Crusher Lower Bearing For

Crusher Bearings for Jaw or Cone for Telsmith, Universal ...

Messinger rock crusher bearings can be found on many rock crushing machine brands, including Telsmith, Cedarapids, El Jay, JCI,, Pioneer (KPI), Universal, and many others. Messinger is one of a few OEMs that has manufactured the large radial and thrust roller bearing parts used in a range of rock crushers used in the industry. Rock crusher bearings by part numbers from stock or fast ...

Crushers

However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage. Cone crushers can in most cases also give a good cubic shape to fine grades. They can be adapted to different appliions. This is an important ...

Serving Industries Worldwide Bearings for Cone Crushers

Cone Crusher Bearing Solutions for the Toughest, Most Demanding Environments. In complement to the manufacture of cone crusher bearings, Scheerer offers a complete line of bearings used in the industry. Appliions include: Additional Products . for the Mining and Aggregate Industries. Upper Cylindrical Roller . Thrust Bearing Tapered Roller Thrust Bearing Lower Tapered Roller Thrust ...

Cedarapids Cone Crusher Bearings

Cone Crusher Bearings. ELRUS stocks bearings for most makes and models of Roller Cone Crushers including Cedarapids, Telsmith, MVP, JCI and Eljay cone crushers. Cylindrical Tapered Thrust Bearings . Optimized surface finish for improved functionality and life cycle. Decreased startup friction and drag through a low profile. cage design.

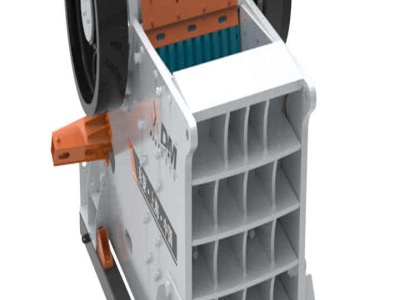

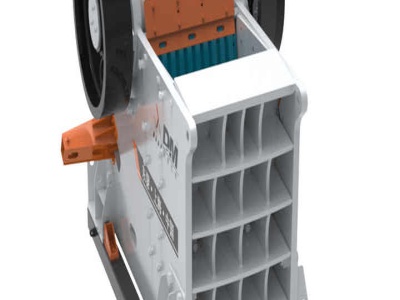

Jaw Crushers

Jaw crushers are used mainly in first stage, primary crushing appliions and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model. Base Units. The RockSizer / StoneSizer upthrust single toggle design ...

Are jaw crusher bearings very important to us?

Answer: Jaw crusher is a machine specially used for crushing stones. It is widely used in mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other departments. It crushes various materials with compressive .

New Type Vertical Crusher

New Type Vertical Crusher. Production Capacity: 815t/h Matching Power: 22kw Applicable Materials: It can be used for the final crushing of various materials such as mixture, gypsum, coal gangue, slag, copper ore. Product Introduction: Product introductionThe new type vertical crusher is a kind of adjustable crusher machine without screen cloth designed on the basis of absorbing the ...

Design of crush height for reliable ...

pressure in high performance bearings may be calculated. Lower stiffness of aluminum and titanium housings, and their thermal expansion rates that are different from steel, should be taken into account in the calculations of contact pressure. At the same amount of crush height, a greater contact pressure is obtained in bearings with a thicker steel back and in more rigid housings (housings ...

Crusher thrust bearing J 940 A for JCI cone crushers ...

Crusher thrust bearing J 940 A for JCI cone crushers Aug 31 2021 0 HS Symons Cone Crusher. HP Multi Cylinder Hydraulic Cone Crusher . DP Single Cylinder Hydraulic Cone Crusher. PY Spring Cone Crusher. Portable cone crusher. Cone crusher price and supplier. HS Series Symons Cone Crusher is widely used in the metallurgical industry, construction materials industry, road building industry ...

Gyratory Crusher Explained

As the eccentric bushing rotates, the lower shaft oscillates in an elliptical orbit around the centreline of the crusher. This action causes the gap between the mantle and concave liners to open and close upon each rotation of the shaft. At the upper end of the mantle this movement is very small, but as the ore falls lower, the throw increases and the crushing force also correspondingly increases.

Crusher Bearings Technical White Paper | Timken

ofownership low in these conditions requires a commitment to proper care, including routine inspection and relubriion of roller bearings in compression and impact crushers. Knowing the common types of bearings used in crushing equipment can help operators and maintenance personnel understand how different designs impact performance. Table of Contents: Compression Crushers 2 Jaw Crushers 2 ...

ZI Cone Crusher | THE STORIES | Kawasaki Heavy Industries ...

ZI Cone Crusher. Supported by two bearings (the upper bearing of the top frame and the lower bearing of the bottom frame). The feed materials are crushed by the eccentric motion of the main shaft. The concave (crushing liner) is assembled inside. It is one of the main wear parts and is replaced during maintenance work if wornout.

Major causes of bearing failure

Bearing "crush", which is designed into the bearing, controls this. Installing a bearing in an undersize housing hole increases crush and will cause the steel back to yield and get thicker at the point of least resistance. This is generally at an oil hole or adjacent to the parting lines if there is no hole. CORRECTIVE ACTION 1. Verify that the bearing installed was correct for the ...

14 Cone Crusher Common Problems And How To Fix Them | MC

Cone crusher trip by low pressure. Reply. Nabam Vijay says: 10/01/2021 at 19:49 . What is the normal lubricant pressure for 250TPH propel cone crusher. Reply. Jason says: 12/11/2020 at 22:04 . Cone crusher won't clear, electrical is fine. Any ideas? Reply. beidoou says: 19/11/2020 at 14:59 . Maybe you need to adjust the cone crusher inlet and outlet parameters according to the change of ...

Jaw Crushers » Armstrong Equipment

The ® Jaques Single Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Typical appliions for our singletoggle jaw crushers are in mining, quarrying and recycling. The jaw crushers handle ores, rock, gravel and recycled concrete.

Roller Crusher | Single/Double Roll Crushers

Rock Roll crusher is fine crusher equipment that similar to the hammer crusher. It can crush the compressive strength of less than 160 MPA of materials. Medium feed size, and adjustable discharge size. With the characteristic of low maintenance costs, low requirements for water, reliable performance, less power consumption, less dust, low noise ...

Latest Posts

- المصنعين الرصاص الكرة مطحنة

- قضبان كربيد نهاية مطحنة

- كسارة متنقلة من الحجر الرملي في جواليور

- مبيعات مطحنة الكرة الطلاء في الجزائر

- مصنع معالجة الحديد في المملكة العربية السعودية

- كيفية جعل رمل السيليكا

- مقاسات مختلفة من مجاميع تكسير الحجارة

- كسارة الحجر تيرازو

- تصميم ماكينات نورتون

- كسارة الحجر سعر المصنع في مصر

- مصنع كسارة 200 طن المملكة العربية السعودية للبيع في المملكة العربية السعودية

- مزدوجة مبيعات كسارة الأسطوانة في المملكة العربية السعودية

- بيع معدات صنع كربونات الكالسيوم

- آلة كسارة قديمة في الولايات المتحدة الأمريكية

- دليل طاحونة مصانع الأسمنت

- Kitco Copper Boulion Oz

- How Mining Crusher Work

- Portable Crushing Screening Plant Alogue Pdf

- Coal Mining In Ukraine Images

- Importance Of Mine Surveying In Mining Industry

- Shy Stone Breaking Machine Crusher

- Beneficiation Of Dolomite In Simi Valley Us

- Gold Mining For Sale In Australia

- Usa Plastic Bottle Crusher

- Conveyor Idler Calculation Excel Sheet Freeware

- Slag Primary Crusher Price

- Sample Calculations For Flexowell Conveyors

- Diagram To Build A Cement Bagging Plant

- Iron Ore Crushing Plant South Africa

- Cheap Japan Rock Mining Mill