Capacity Air Swept Coal Mill

What Is Coal Mill In Cement Plant

Coal Mill In Cement Plant, Airswept Coal Mill Coal Mill. The coal mill adopts an edge driving system, is driven by the motor through the reduction gear and large and small gears. Raw coal is fed into feeding device of coal mill in cement plant, the hot air with temperature about 300 ℃ through the duct into the feeding device, there is a. Get ...

Coal grinding technology: a manual for process engineers ...

The mills examined are the: airswept ball mill, roll or ball and race types of mills, airswept hammer mill, and wet overflow ball mill. The handbook is not intended to be an exhaustive guide to design and practice since separate books could be written on each system. Instead it is a guide for the process engineer who must select a coal grinding system as part of a larger coal conversion ...

Grinding Equipment_Henan Zhengzhou Mining Machinery Co., Ltd.

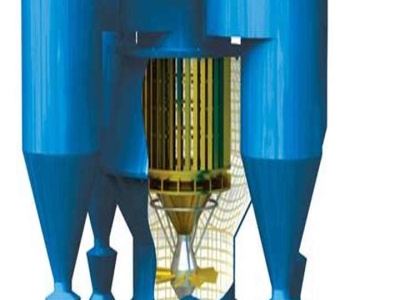

Air swept coal mill is consist of feeding device, main bearing, rotating parts, discharging device, high pressure starting device and lubriion system. And the feeding device is consist of feed pipe, blast pipe and etc. FEATURES . OUR ADVANTAGE. grinding efficiency and low energy consumption; metal consumption per unit of products; operation, and large production ...

Function Of Dynamic Classifier On Coal Mill

Coal Mill Classifier Vanes. usa classifier vane for coal mills google patentsan improved vane of the type with adequate mill grinding capacity, the mps mill equipped with six static classifier is the further from the 200 and less than 325 mesh without increasing mill pressure drop. installation of dynamic vane classifier in coal mills in.

Air Swept Coal Mill China Manufacturer

Air swept coal mill is used for drying and grinding pulverized coal. It mainly consists of feeding device, main bearing, rotary part, transmission device, ballast device, highpressure starting device and lubriion system. Raw materials are loaded into the mill by feeding equipment, hot air enters the mill through the air inlet tube. With the rotation of the mill barrel, coal and hot air ...

A Comparison of Three Types of Coal Pulverizers

The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal. Grinding pressure can be adjusted to account for variations in coal grindability and desired product fineness. Raw coal is fed through a ...

The Storm Approach to Coal Pulverizer Optimization

to as the mill capacity. We prefer to discuss coal throughput as one of the three major components of capacity (Hardgrove grindability and fineness are the other two). Take one version of a typical correction curve for a pulverizer rated at 125,000 lb/hr as shown in Figure 2 for an HGI of roughly 50 and 70% passing a 200 mesh sieve (green line). Figure 1: Typical MPS89 with Storm Components ...

drying in a mill coal

Air swept coal mill,coal grinding dry ball mill for sale. The airswept coal mill is mainly used for drying coal powder and crushing coal powder. The airsweep coal mill adopts advanced and reasonable structural devices, which has the advantages of reducing energy consumption, long service life, fewer wearing parts, large yearonyear output, and difficult to get price. Reduction of CAPEX in ...

PULVERIZING BALL FROM KENNEDYVAN SAUN AIR SWEPT TUBE MILL .

The Kennedy Airswept Tube Mill uses air to remove the pulverized coal leaving behind the larger particles that need additional puliverizing. ADDITIONAL INFORMATION: [From "Marine Development of Pulverized Coal" by Comdr. J. S. Evans and Brierly, page 407] The Mercer is a 9500ton cargo vessel built by the Federal Shipbuilding Co. at Kearney,, in 1920. It is equipped with a 2500 ...

China Cement Machine Leading Manufacturer, Rotary Kiln ...

Grinding Mill. Ball mill, raw mill, mining mill and air swept coal mill are pengfei featured products. Best grinding equipment supplier Pengfei.

What Are the Main Components of AirSwept Coal Mill?Fote ...

· Airswept coal mill is the main production facilities in cement plant's, its main role is drying and grinding coal powder, fine powder with hot air after passing through a cyclone dust collector separately. In recent years, airswept coal mill has been widely used, and has features of reliability, large capacity, high efficiency, easy maintenance and so on. So, what the main components of ...

Airswept Coal Mill

The airswept coal mill is brim driven by motor through reducer and gears. It has airswept structure with drying chamber, which allows the coal mill to accept raw material with different moisture. Inside the cylinder there is in sequence stepped lining plate, double stepped lining plate and ripple lining plate, which increase the capacity of the coal mill. The shutterstructured inlet can ...

ulhasnagar air swept coal mill processing bluestone

Amravati air sweep coal mill processing basalt Coal dust is a type of fine coal powder ground by coal grinding mill size range 005001mm and most of powder's size range 2050μm Pulverized coal processed by grinding machine could be fully burned use ratio very high and we have provided technical support for many power plant Read More . ulhasnagar air swept coal mill processingcement ...

Coal mill

CHAENG Coal Mill is also called the air swept coal mill. It is used for grinding and drying the coal with all kinds of hardness. vip + ; Online Service; Global website English; ; Español; Русский; العربية; Video; Project; Gallery; HOME; PRODUCTS. Vertical Roller Mill Steel Slag Vertical Mill Coal vertical mill Raw material vertical mill ...

coal mill differential pressure | worldcrushers

· However, the mills had never performed at this level and the base capacity of K#/hr . mill differential pressure is high due to coal flow. Pressure ? Georgia State University. In the high velocity flow through the constriction, kinetic energy must increase at the expense of pressure energy. Coal Mill Differential Pressure | Crusher Mills, Cone Crusher . ball mill supplier,ball mill ...

Coal Mill

The grinding mill adopts airswept structure with a drying bin, so that it had strong adaptability to the water containing in the raw coal. Inside the powder grinding cabin, the ladder lining board, doubleladder lining board and ripple lining board are arranged in a combined type, thus improving the powder grinding ability of the grinding mill. The feeding device adopts windowshade structure ...

Coal Pulverizer Design Upgrades to Meet the Demands of Low ...

The MPS mill is classified as an airswept, pressurized, vertical spindle, table/roller mill. It contains an integral classifier, a grinding section, a windbox (plenum), and auxiliary components. (Figure 1) Frequency converted electric drive Turret Louvre Return hopper Pendulum joints Housing Hot air inlet duct Grinding track carrier Motor Foundation Rotating cage Rotary classifier SLS Sealing ...

Air Swept Coal Mill

This air swept coal mill is specially used to dry and grind coal. And it is mainly consist of feeding device, main bearing, rotary part, transmission device, high voltage starting device, and lubriion system. Raw materials enter into the mill by the feeding device, and the hot air gets into the mill through the air tube. When the mill cylinder begins to rotate, coal and hot air can exchange ...

Coal Grinding in Air swept mills

Coal Grinding in Air swept mills. We are having an air swept mill for coal grinding. we are getting washed coal in rakes whichis unloaded in the raw coal hopper in the hopper is covered by railing to screen big lumps of rock. The size of rocks vary between majority size of washed coal is around 3mm with a volatile matter of 2830 %. The problem is that the mill gets ...

Air Swept Coal Mill

Air Swept Coal Mill Coal Mill LK Products Made In China, China Manufacturer. CIC HMC can design and produce below 5m coal mill. These mills are widely used for dry pulverizing of coal with different hardness, and main equipment of pulverized coal preparation system in cement industry, thermal power generation and chemical industry. ★AirSweptCoalMill:Model φ~φ ...

Pulverizers 101: Part I

· Most MPS89 pulverizers are rated for about 125,000 pounds of coal per hour, often referred to as the mill capacity (Figure 1). We prefer to discuss coal .

Steady state inferential modeling of temperature and ...

· The model relates primary air flow (kg/s) to the mill demand as presented in Eq. . (1) PA = ⁎ Mill demand + 38. Mill loadingThis refers to the level of coal inside the mill during its continuous state of operation. The power consumption of the mill varies with the coal loading inside the mill. During plant operation, any increase ...

Coal crusher machine,coal grinding mill plant, mobile coal ...

Air swept Coal Ball Mill is the main equipment in cement plant for both drying and grinding of the powders. Compared with the ordinary ball mill, it has advantages of higher capacity, more convenient operation, safer usage, and more reliable performance. Coal Processing Plant Line . NO. Equipment: Model : Motor(KW) Number : Hopper: LC3000X4000 : 1 : I : Vibrating Feeder: ZSW490×130: 22: 1 ...

Latest Posts

- سعر كسارة الفك المحمولة في السودان

- كسارة مخروط ذروة

- الولايات المتحدة الأمريكية الشركات الحجر معدات المطحنة

- عملية طحن التلك

- كسارات مخروط اليابان

- تخطيط مصنع طاحونة الأرز وتكلفة المشروع

- لوحات الخد كسارة الفك

- سعر آلة كسارة الحجر في uttarakhand المستخدمة

- مورد حجر النهر في أبوظبي

- الكسارات المستعملة للبيع في تورونتو

- مطحنة الكرة المستخدمة للبيع سيبو

- الحجر المحمول الكسارات ه في أستراليا

- تجهيز الذهب الصخور الصلبة

- مصنع تكسير الأحجار بجدة

- سعر معمل طحن الرخام فى مصر

- Ultrafine Ring Roller Mill

- Sand Classifier For Sale Philippines

- Sand Making Machine Coimbatore

- New Building Materials Construction World Supplier

- Welcome To Disha Processing Company We Are Engaged In

- Parts Used In Construction Of Hammer Mill

- Explossive Use In A Open Cost Mining Iron Ore Mines In

- Crusher Price Plant

- Coal Crusher Electric Motor Drive Kv

- Pegmatite Fine Powder Mill

- Quarry Crusher In Germany

- Milling Machine Afternoon

- Pebble Crusher Design Criteria

- Field Rock Crusher

- Crusher Yang Onlinelokasi