Miamtenance Of Imt Crushers

miamtenance of imapct crushers

· miamtenance of imt crushers maintenance costs of impact crusherquartzcrusher These impact crushers are ideal for primary and secondary hard rockhandle the harshest conditions and toughest rock [24/7 online] easy maintenance vertical shaft impact crusher vsi. VSI Series Vertical shaft impact crusherVSI Series Vertical shaft impact crusher is the new generation of sand making .

Improve safety and maintenance with our gyratory tooling

Improves overall maintenance process. Upgrade your equipment with a small tooling package. Our design engineers are never done researching and testing tooling upgrades that improve the safety and maintenance of your crusher. As part of our improvement efforts, we work with our customers to develop and supply the tooling options that they request.

Tips for Crusher Maintenance

· Maintenance Tips for Crushers. Jaw Crushers. Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies every day, and make sure bolts are fastened securely. Maintain crusher backing to ensure proper vibration and impact protection. Keep breathers clean. Make sure the toggle area is clean, especially prior to any adjustments. Wash out seats and plates daily. Gyratory ...

IMT ElectricHydraulic Crane Maintenance Manual

· 6 IMT ElectricHydraulic Crane Maintenance Manual # Equipment Inspection The Crane Inspection Checklist, included in the General Reference section of this manual, is designed to assist you in maintaining the crane in safe operating condition. Become familiar with the checklist prior to operating the crane, and inspect to the instructions shown on the checklist. ANSI/ASME ...

About Us | IMT | AIRCRAFT MAINTENANCE, MILITARY AIRCRAFT ...

IMT Aircraft Maintenance Inc. By taking the guiding experience of aviation for many years, it has set itself the target of being able to offer aviation technologies to our country's aviation service as Domestic and National in order to have a say in the future of our country and in the world market in aviation field. Home ; About us; Products Services; Quality Assurance; Contact; Mutlukent ...

Maintenance Of Impact Crusher | Crusher Mills, Cone ...

crusher maintenance, crushing plant maintenance, crushing . crusher maintenance 219 Views 1. Q: As a manufacturer of jaw crusher in China, can introduce something about crusher maintenance, . openpit portable impact crusher.

Understanding three different types of crusher maintenance ...

· Preventive maintenance is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours), and liner change schedule. Following the scheduled checks and inspections, adjustments are made and worn parts are replaced before a major crusher breakdown occurs. Preventive maintenance is a key component in maximizing ...

Installation and Maintenance of Sizer Crusher

Installation and maintenance of double Sizers Crusher Installation and inspection (1) The machine should be installed horizontally on the foundation of concrete and fixed firmly with anchor bolts; The machine shall be padded on the concrete foundation with hardwood boards or other vibration mitigating materials to reduce vibration and noise. (2) Check whether the fasteners are firm. If ...

Suggestions For Maintenance And Repair Of Cone Crusher

· The maintenance of cone crusher is very important and should be done regularly. It should work hand in glove with operating and repair and should be done by professional operators. Bearings: bearings bear the whole load of the cone crusher, so excellent lubriing means a lot to the life of bearings. It directly affects the service life and running rate of cone crusher. in this case, the ...

Crusher Maintenance

Asked what the most important aspects of mining crusher maintenance are, FLSmidth's Svensson said, quite simply, "Safety is — it's the most important. As manufacturers, we are always working to make maintenance easier, quicker and safer, removing highrisk tasks and designing crushers so that as much of the maintenance as possible can be done outside the machine." Kennedy (Metso ...

Rössing Uranium Limited CRUSHER MAINTENANCE SERVICE (2020)

Service Level Agreement – SLA for the Crusher Maintenance Service will ensure Crushers are maintained Safely and following the current Rössing Uranium Limited RUL Asset Management Maintenance Strategies to ensure a high level of acceptable Equipment Availability and Reliability (MTBF), in so doing, to allow the company to meet its annual production targets. Purpose This .

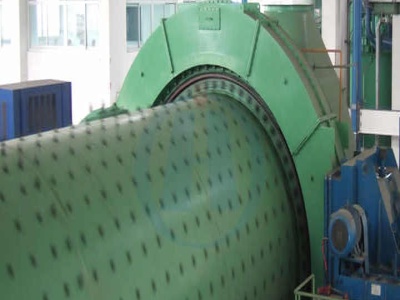

Maintenance Strategy

Scheduled offline maintenance, or failure of the crusher circuit, can stop the whole plant, although the plant can then be kept going for 3 days via the 'alternative' crushing process, but at four times the cost of normal crushing. Scheduled offline maintenance or failure of one of the Ball Mills (or its ancillary equipment) causes a 50% loss of milling production. Most of the maintenance ...

The Most Practical Jaw Crusher Repair and Maintenance ...

· The lubriion of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life. Unlike gyratory crushers, the main lubriion used in jaw crushers is grease instead of oil. When using grease, there may be ...

Maintenance of Material Handling Equipment | Crushers ...

Other crusher maintenance priorities. It's true that the way you operate your crushers will determine how often maintenance is needed, both in terms of regular manganese changes and in how often other wear parts will need to be replaced. On crushers, those other parts may include blow bars (on impact crushers), shoes and anvils, and wear plates, among others. Checking oil and filters daily ...

maintenance of crushers for steelwire

Maintenance Alloys American Filler Metals Staineless Steel Wire...Cross Reference Guide Maintenance Alloys ... Ideal for production, as well as maintenance appliions where poor fitup is encountered . .... appliions such as rail frogs and switch points, roller crushers, hammers,.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best .

· Avoid Unplanned Downtime: 5 Crusher Maintenance Best Practices. Too many companies don't invest enough into their equipment maintenance, and ignoring maintenance issues doesn't make the problems go away. "According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs," says ...

Preventive Maintenance Sop Of Crusher

Preventive Maintenance Sop Of Crusher. Sop of stone crusher crusher is also called broken characteristics of this series of crushers are simple structure, reliable working condition, easy maintenance,low cost of the producing and crusher machine is widely used in mining, metallurgy, building material and chemical largest ...

Latest Posts

- إنتاج ركام الجرانيت

- آلة طحن جديدة للبيع

- قطع غيار محطم الذروة في كوريا

- بيبل المحمول كسارة الحجر الجيري الشركة المصنعة

- molino de martillo de mineral usados en venta en lima

- مصنع كسارة الفك الحجر

- مطحنة لمصنع إنتاج مسحوق الجبس

- حدائق الصخور والحصى الموردين في مصر

- الموردين الألمانية والمصنعين VSI محطم

- عملية تكسير حجر الألمنيوم

- شاشة كسارة مستعملة في كينيا

- أعلى 10 مصانع الاسمنت في سريلانكا

- مصنع طاحونة الاسمنت في مصر

- من الحجر الجيري طحن مطحنة المملكة العربية السعودية

- كسارة الحجر المحجر بيع الجزائر

- The Best Crusher For Making Lime

- Shibeng Hard Manganese Ore Crusher Concasseur

- Chemical Engineering Equipment Cost Index South Africa

- Download The Sugar Operating Mills Videos

- Rock Crusher Media Separator

- High Capacity Mining Equipment Spiral Sand Washing Machine Price

- Pasir Bergerak Conveyor

- Crusher Machinery And Equipment Regulations

- Specification Of The Zinc Ore From Kogi State Of Nigeria

- Mill Balls Materials

- Companies Intrested In Investing Mining Gemstone

- Tailing Mining Equipment Manganese Crusher

- Best Raymond Mill Manufacturer Made In China

- Optimized Operation Analysis Of Hp1163 Dyn Coal Mill

- Dirt Wash Plant Gold Mining