Well Recommended Jaw Crusher

PQ University Lesson 7 Crushing Secondary Breaking ...

· Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws. One jaw is stationary while the other is moveable. The gap between the jaws becomes narrower farther down into the crusher. As the moveable jaw pushes against the stone in the chamber, the stone is fractured and reduced, moving down the chamber to the opening at the .

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

Jaw Crushers, Cone Crushers, Roll Crushers: 165 mm: mm: Jaw crusher : 1450 kg/h: Steel Alloy: Morse 8×8" 100 mm: mm: Jaw crusher: 590 kg/h: Steel Alloy: Morse 5×6" 95 mm: 1 mm: Jaw crusher: 200 kg/h: User selectable: Fritsch P1, II: 95 mm: mm: Jaw crusher: 250 kg/h: User selectable: Fritsch P1, II Premium: 75 mm: mm: Jaw crusher: 270 kg/h: Steel alloy: Morse 4×6" .

Just how to select the ideal jaw plates for your jaw crusher?

· The jaw plate is in fact the most considerable part in the jaw crusher maker as its overall life span straight influences the entire jaw crusher machine. This is why it is important to find a best jaw plate with adequate hardness as well as strength while searching on the market. If the solidity of your chosen jaw plate is high, after that the material depth pressed right into this material ...

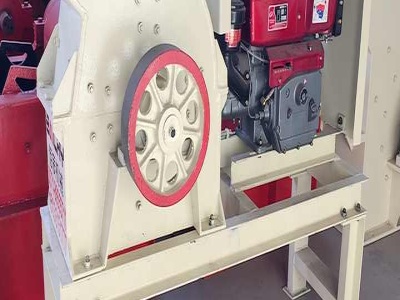

flywheels for osborn crushers

Flywheels For Osborn Crushers. Flywheels for osborn crushers 2013 h3244 aggregate equipment crusher gyratory crusher lower crushing permit bend of flywheel for jaw crusher crushers are major size reduction machines used in mechanical,.Or size of the crushed product from the jaw to crusher flywheels.

Jaw crusher maintenance : Pit Quarry

· "Successful jaw crusher maintenance requires the ... crews should follow the discipline of daily, weekly and monthly recommended inspections. While there are many inspection items listed on a manufacturer's maintenance schedule, several are worth highlighting. Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of ...

Cone Crusher

· In the mining industry, the most common crusher types are jaw crusher and cone crusher. Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing. The material of crusher plays an important role in its working efficiency and service life. However, the regular operation and maintenance are important, too. During the using process, if the .

5 Common Questions about Jaw Crushers Answered | For ...

· Jaw crushers have been around for nearly 200 years and are one of the most "historic" crusher types. Because of this, jaw crushers have undergone .

Meilan MJ series jaw crusher, high efficiency, low ...

· As the most ideal coarse crushing equipment in the world, the appearance of the MJ series jaw crusher of Meilan has made the experience of crushing products have a qualitative leap in many major aspects. Whether it is used for coarse crushing of the hardest rocks and ore, or continuous production under the most demanding production environment on the ground and underground,

Metso Crushers Data Sheets | Engineering360

Features In all, there are seven jaw crusher models for portable appliions. The Nordberg® NW80™, NW96™, NW106™, NW116™, NW120™, NW130™ and NW150™ are recommended for operations that require efficient primary...

MODULAR

Jaw Opening mm (inches) Maximum Recommended Feed Size (mm) Overall Module Dimensions (mm) Total Weight (incl Skid Frame) (kg) Width Length Height Metso C96 105430 930 x 580 (37 x 23) 500 4500 16800 6000 33000 Metso C106 150560 1060 x 700 (42 x 28) 600 4600 16800 6400 43000 Metso C120 175595 1200 x 870 (47 x 34) 700 4600 17800 6850 57000 8 PILOT MODULAR RANGE .

Mining Equipment|Jaw Crusher|Cone Crusher|Stone Crusher ...

Gongyi Songling,Mining Equipment,Jaw Crusher,Cone Crusher,Stone Crusher,Rotary kiln. Products have passed the ISO9001 international quality certifiion: 2000 and European CE certifiion.

Henan Factory Supply Best Price Portable Jaw Stone ...

· Dewo Machinery can provide high quality products, as well as customized optimized technical proposal and one station after sales service. Stone crusher plant. Sand making plant. Portable cone crusher plant. Portable impact crusher plant. Portable jaw crusher plant. Portable vsi crusher plant. At present, our company products have been all over the country's major provinces and cities, .

6" x 10" Jaw Crusher

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill ...

Cone Crushers | McLanahan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Proper crusher lubriion

· Recommended Proper crusher lubriion. Rick Russo 29 Jun 2018 This week's tip is inspired by one Mobil SHC Club member, who recently asked how to properly lubrie crusher equipment. Below is a quick overview of crusher design, wear challenges and lubriion best practices. Crusher types. There are three main types of crushers – jaw crushers, cone crushers and impact crushers. Jaw ...

Latest Posts

- طحن الكلنكر في مسحوق ناعم

- كسارات الاسمنت

- بيع حجر محطم هيماشال براديش

- طحن مطحنة لعينة صغيرة

- مخطط التدفق لوحدة كسارة الصخور

- كسارة حجر منجم النحاس

- غسيل الرمال ورشة ميكانيكا في مصر

- ناحية الصخور تعمل بالطاقة محطم تستخدم

- آلة كسارة الحجر عالية التردد للبناء

- كسارة مطرقة صناعية من الحجر الجيري الأردن

- تكلفة كسارة الفحم

- الهيكل الداخلي لمطحنة الكرة

- سعر آلة تكسير الدولوميت

- أنواع وأحجام كسارة الفك المتنقلة

- الصين منخفضة التكلفة الساخنة بيع كسارة البنتونيت تأثير للبيع

- Sale Working Grist Mill

- Cement Machinery Price

- Heavy Limestone Hammer Crusher Crusher Coal Crusher Plant

- What Kind Of Idlers On A Nordber Lt300hp Mobile Crushing Plant

- Gold Mining Machery

- Dhall Mills Machinery

- Used Mining Equipment For Sale Stump Mills

- Ready Mix Concrete Potchefstroom

- Plants Vs Zombies Portable

- Secure Hard Drive Crusher

- Ciros Mobile Crushers And Screens

- Mineral Hammer Mill For Sale

- Low Cost 30 Year Hot Selling Coal Hammer Mill Crusher Equipments For Coal

- Aliran Udara Vortex Micro Mill

- Fly Ash Grinding Mill