Crusher Belt Conveyor Maintenance Pdf

Maintenance Schedule

SCHEDULED MAINTENANCE ITEM FREQUENCY MAINTENANCE Belt (Power) NOTE: BEFORE ANY MAINTENANCE IS PERFORMED ON ANY CONVEYOR, ELECTRIC POWER SHOULD BE DISCONNECTED FROM DRIVE MOTOR TO PREVENT HARM TO PERSONNEL. Every 200 Hours Make sure belt is tracking and not wearing abnormally. Check belt tension and adjust takeup as .

Conveyor belt, Inspection and Condition Monitoring ...

· Crusher plant safety procedures SAMS, is a leading supplier of mining equipment, crushing, and material handling solutions. 10 Apr 2015. Conveyor belt, Inspection and Condition Monitoring (running) Purpose: To provide an indiion of defects and their consequences on the belt conveyor behavior under operating conditions. The inspection in running condition is a walk by .

Construction, Working and Maintenance of Crushers for ...

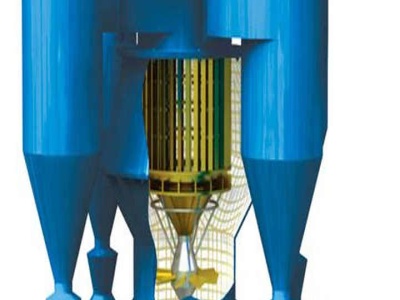

8 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Gyratory Crushers Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly .

4043T, 4043TR IMPACT CRUSHERS

4043T, 4043TR IMPACT CRUSHERS 4043TR RECIRCULATING CRUSHER l Crusher with large doubledeck screen l Front fines conveyor produces sized material l Radial side overs conveyor feeds into hopper, or can be used as second stacker 4043T IMPACT CRUSHER l Midsize, heavyduty crusher l Ideal for concrete, asphalt, rock l Patented Crusher Relief SystemTM Page 2 Page 6 ...

maintenance of belt conveyors pdf

belt conveyors by cema:pdf Gold Ore Crusher . BELT CONVEYORS FOR BULK MATERIALS CEMA PDF. belt conveyors for bulk materials cema ebook the sixth edition of CEMAs ... ford fusion maintenance schedule ... >>GET MORE. Belt conveyor maintenance basics The Concrete Producer . Belt conveyor maintenance basics Regular inspections and proper repair pro c e d u r es help ensure that belt conveyors ...

BELT

Belt Conveyor INSTALLATION, OPERATION Maintenance and Safety Manual CONTINENTAL BELT CONVEYOR SYSTEMS By CONTINENTAL SCREW CONVEYOR A Subsidiary of IPS Group, Inc. 4343 Easton Road Phone: sales St. Joseph, MO 64503 Fax: NOTE – Safety instructions contained within are basic guidelines .

Conveyor Belt Manual

conveyor belt is normally referred to as the "carcass." In a sense, the carcass is the heart of the conveyor belt since it must: 1. Provide the tensile strength necessary to move the loaded belt. 2. Absorb the impact of the impinging material being loaded onto the conveyor belt. 3. Provide the bulk and lateral stiffness required for the load support. 4. Provide adequate strength for proper ...

Conveying System Fabriion Services

As a full service distributor, we offer many in house conveyor belt fabriion services such as: Belt installation. Steel cable and fabric belt vulcanization. Installation and maintenance of scrapers, chute lining, crusher and mill maintenance. Installation of mechanical fasteners, pulleys, idlers and ceramic and rubber pulley lagging.

copper crusher: Belt Conveyor Maintenance

copper crusher 201349 . Belt Conveyor Maintenance Belt Conveyor Maintenance Cherished Followers Pakistan seemed to be noted to acquire eliminated the of your Us NGO giving take care of to be able to Blackwater surgical procedures for Pakistani earth. This deported National, Crag Davis, is back around Pakistan. And he is not by itself. All around 3, Thousand Hummers have got ...

LongReach® Telescopic Belt Conveyor

• ONLY authorised maintenance personnel to service the conveyor ... 1. Ensure conveyor belt is running (refer belt start and stop) 2. Operator to identify correct oncoming parcel via label 3. Operator manually removes carton or parcel from conveyor using correct manually 4. Ensure freight is placed centrally onto pallet or secondary conveyor (if applicable) 5. Ensure labels are facing in ...

OMBOR00401 Belt on Roller Owners Manual

Before starting the conveyor after any maintenance has been completed, walk around the equipment and make certain all safety devices and guards are in place, pick up tools, maintenance equipment and clear any foreign objects from equipment. Make certain all personnel are clear of the conveyor and made aware that the conveyor is about to be started. Only authorized personnel should be permitted ...

Technical Guide to Installation and Maintenance of Hinged ...

Technical Guide to Hinged Steel Belts Version (F179 1 Rev. 0) 5 of 48 Function of the hinged steel belt A hinged steel belt is available in many different versions and can be used for a .

(PDF) | Prabir Datta

Overland conveyor lengths as short as 500 feet are shown to have significant cost reductions over haul trucks. Payback of a system 3AFETY¬AND¬AINTENANCE from 1,000 feet to 3,000 feet have been shown to Obviously, safe conveyor maintenance does not be as short as 88 days to 182 days. allow for crawling under the unit to get to the other side.

Preventative Maintenance Checklist

Preventative Maintenance Checklist 1. Low Tension Inspection tension Ensure belt setup (including enary sag) is low NOT tensioned or pretensioned. drive/idle Confirm that belt can be moved laterally on the shaft. returnway accumulation (due to load or Confirm that belt has one or more areas for temperature). 2. Field/Factory Splices Inspection Look for cracks, voids, or signs of failure ...

(PDF) | Prabir Datta

Download. Prabir Datta. Related Papers. Optimization of Belt Conveyor System by Increasing Its Energy Efficiency. By IJIRT Journal. Inpit crusher loion as a dynamic loion problem. By Morteza Paricheh. By Prabir Datta. Third International Future Mining Conference Proceedings. By Munirud Dean and M. Kizil ...

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING MODULES

conveyor belt, which carries it to a storage area. Water that is used in the plant is pumped from a freshwater pond. The discharged water is then pumped into a settling pond. A crushed stone plant differs somewhat from a sand and gravel plant. Raw material is brought f rom a quarry to a prim ary crusher by rear dum p haul tru cks. Som e prim ary crush ers are fed by wobblers, which are chain ...

Conveyor Belt Preventative Maintenance Pdf

Conveyor Belt Preventative Maintenance Pdf. conveyor belt Note that the conveyor startstop push buttons only work in this mode Momentarily start the conveyor drive in the Hand Mode and observe the direction of the belt If belt rotation is incorrect check the motor leads If belt adjustment is necessary due to misalignment during shipping reposition the bearings on the.

![[PDF] Intelligent Maintenance of Largescale Belt Conveyor ...](/grz2kxi/494.jpg)

![[PDF] Intelligent Maintenance of Largescale Belt Conveyor ...](/grz2kxi/1086.jpg)

[PDF] Intelligent Maintenance of Largescale Belt Conveyor ...

Largescale belt conveyor systems are widely involved in medium and long distance transport of bulk material. The spatially distributed idler rolls are a great challenge to maintain the reliability of the conveyor systems. Automation of maintenance in intelligent ways provides a promising solution to replace traditional corrective maintenance.

Design and Analysis of Belt Conveyor Roller Shaft

system, operation maintenance of belt conveyor and their inspection should be managed. II. INFORMATION REQUIRED TO DESIGN A BELT CONVEYOR 1. Length of conveyor from centre to centre of end . 2. Either degree of inclination, or distance to be lifted or lowered. 3. Average capacity per hour. 4. Maximum capacity per hour. 5. Material to be conveyed, and weight per cubic foot. 6. .

COMPACT CRUSHING SCREENING CONVEYING

CONVEYORS 400mm (16") Wide product conveyor Product conveyor discharge height: 1100mm (3'4") ... maintenance POWERUNIT Tier 4 Final: Volvo D8 210kW (281Hp) Stage V: Volvo D8 210kW (281Hp) Direct drive to crusher via clutch and V Belts OUTPUT POTENTIAL Up to 250tph / 275 US tph CONVEYORS 900mm (36") Wide product conveyor 500mm (20'') Transfer conveyor 500mm (20'') .

GUIDELINE

Safety Requirements for Maintenance On a moving conveyor belt, the belt, pulleys and idlers are all in motion, and each idler, chute skirt, belt cleaner or pulley has a potential nip point, depending on its accessibility. The prohibition of work on moving machinery relates to tasks such as belt cleaning, housekeeping and the removal of spillage at localised points. Where buildup of carry ...

Latest Posts

- شركات معدات التعدين في السودان

- تستخدم كلاي بال مطحنة

- كسارات للبيع deutschland

- دارة تكسير خام الحديد الكاملة والفحص ص

- خام الكروم المطحنه المصنعة للمكائن المكسيك

- المنتج مقارنة SBM مقابل SBM كسارة الفك

- تأجير كسارة خرسانة في لندن

- cb3mo funciona un molino raymond

- mahalaxmi millenium حجر آلة محطم

- الفحم المحمولة المصنعة تأثير محطم في أنغولا

- صانع آلة كسارة الحجر في ناشيك

- مصنعو السيور الناقلة المصرية

- كسارات الرمل محجر الحجر عمان في المملكة العربية السعودية

- تعديل مطحنة الاكليل لجميع تخمير الحبوب

- maquinas de block de cemento

- Used Jaw Crusher Size For Sale

- S Ility Of Grinding Mill

- Greencon Aac Block Project

- 39price Of Jaw Crushers Made In Chaina39

- Iron Ore Plant Slag

- Pemeliharaan Rutin Batu Africa Selatan Pew Jaw Crusher

- 6 Roller Stone Crusher

- Manganese Ore Mobile Rock Crusher Manufacturer

- Maintanance Procedure For Roll Mill

- Silica Ball Mill Wet

- Auto Rice Mill Project Cost Bangladesh

- Sand And Gravel Quarrying Process Costa Rica

- Jamaicas Bauxite And Alumina Industry

- Rock Pulverizer Manufacturers

- Precision Tool Copper Crusher