Appliions Micro Scale Milling

DryED milling of microscale contours with highspeed ...

· This paper presents machining results for dryED milling of microscale contours by use of a new machine tool, including a relaxation generator, designed for dryEDM. To implement the dryED milling process tungsten tube electrodes were used. The gas is injected through the tubular tool electrode under high pressure. Additionally, a highspeed EDM spindle was used to overcome process ...

Surface Roughness Conversion Chart Tables Engineers Edge

Ra = Roughness, average in micrometers microinches RMS = Root Mean Square in microinches CLA = Center Line average in microinches Rt = Roughness, total in microns N = New ISO (Grade) Scale numbers CutOff Length = Length required for sample. Conversion math at bottom μ== . μin= in= μ

Laser micromachining, explained by RP Photonics ...

Laser micromachining means machining (subtractive processing) on a micrometer scale using laser light. It includes processes like microdrilling, cutting, milling, marking and structuring, and can be applied to a wide range of materials including metals, ceramics, semiconductors, glasses and crystals, polymers and composite materials.

Grinding Technology Theory And Appliions Of Machining

Grinding Technology Theory And Appliions Of Machining. Practcical appliions of grinding mills Home. practcical appliions of grinding mills. A Practical and Optimal Approach to CNC Programming CiteSeerX. grinding wheel profile that is used on a 2 axis grinding machine however, the flute shapes are only exact on To address these problems, a practical and optimal approach for five axis grind ing ...

MicroMark

To order by phone, call. . MicroMark. 340 Snyder Avenue, Berkeley Heights, New Jersey 07922

Micro Machining UK | Small Parts CNC Machining | Miniature ...

By adapting a 3 Axis Milling machine we are not limited to the components we can create. We can adapt our machines, our workflows and our factory to any job. This gives us flexibility, adaptability and high quality. And because we don't have a dedied machine only specialising in Micro Machining, we can keep the costs down for our customers as well. Our machines create such minute details ...

(PDF) Towards a physical comprehension of material ...

Towards a physical comprehension of material strengthening factors during macro to microscale milling. Dr Muhammad Asad. Related Papers. Numerical and Experimental Approach for an Aluminium Alloy MicroMilling. By Muhammad Asad. On the turning modeling and simulation: 2D and 3D FEM approaches. By Muhammad Asad. Cutting simulation capabilities based on crystal plasticity theory .

Microfabrica

30/08/2021 · VAN NUYS, Calif. (BUSINESS WIRE)Microfabrica, the world leader in Advanced MicroScale Additive Manufacturing and the wholly owned and independently operated subsidiary of Italian multinational Technoprobe SpA, is debuting its latest generation of MicroComposite MEMS™ Probes during the 30th annual SWTest 2021 conference and expo.

Experimental Study on Machinability of Ti6Al4V in Micro ...

microscale endmilling process of titanium alloy – Ti6Al4V by investigating the effects of machining parameters on milling forces, burr formation, chip morphology, and tool wear, respectively. The experimental results show that large feed per tooth (5 um/tooth) results in the increase in the resultant milling force and that large spindle speed (60,000 RPM) and feed per tooth (5 um/tooth ...

A stateoftheart review of micronscale spatially ...

· The sequential ringcore milling focused ion beamdigital image correlation method allows micro to macroscale mapping at the step of 10–1000 μm, while the parallel focused ion beamdigital image correlation approach exploits simultaneous milling operation to quantify stress profiles at the micron scale (1–10 μm). Crossvalidation against Xray diffraction results confirms that these ...

Simulation of micromilling Inconel 718 considering scale ...

· To study the scale effect during micromilling process, we establish a modified JohnsonCook (JC) constitutive model to describe the strengthening behavior of materials on microscale based on the theory of strain gradient plasticity. The VUMAT constitutive subroutine of Inconel 718 is programmed. The radius of the tool edge and its influence on the rake angle are considered. Based .

Microstructure effects on process outputs in micro scale ...

Micro milling experiments were performed on each sample and process outputs such as cutting forces, areal surface texture, builtup edge (BUE) formation, and alterations in the microstructure were investigated. Electron backster diffraction (EBSD) analysis was used to investigate the microstructure of the machined surfaces. It was observed that smaller grain size (both α and β) and lower ...

SPACEOPTIX

SPACEOPTIX is a Fraunhofer IOF spinoff founded in early 2020. We engineer, manufacture, integrate, and test highperformance metal optical components and systems for appliions in space, astronomy, science, and industry.

A Comprehensive MicroMilling Force Model for a Low ...

· A Static Model of Chip Formation in Microscale Milling. J. Manuf. Sci. Eng (November,2004) Material Strengthening Mechanisms and Their Contribution to Size Effect in MicroCutting. J. Manuf. Sci. Eng (August,2006) Related Proceedings Papers. MicroMachinability Studies of Single Crystal Silicon Using Diamond EndMill . MSEC2016. Experimental and Modeling Analysis of .

Deburring of MicroScale Structures Machined in Milling ...

· The paper presents a deburring process to remove the burrs on the microscale structured surfaces, which are machined in micro milling. In order to remove the burrs on the pillars in the structures, the study examines burr removal milling, polishing and water jet finishing. Burr removal milling leaves the cutter traces with adhesion of the chips on the pillars. Polishing finishes the .

MODELING AND OPTIMIZATION OF MICRO SCALE POCKET MILLING .

MODELING AND OPTIMIZATION OF MICRO SCALE POCKET MILLING OPERATIONS A THESIS SUBMITTED TO THE DEPARTMENT OF INDUSTRIAL ENGINEERING AND THE GRADUATE SCHOOL OF ENGINEERING AND SCIENCE OF BILKENT UNIVERSITY IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF SCIENCE by Bengisu Sert May, .

Sample Pages Micro Injection Molding

Polymer pvT Properties at the Micro Scale ..... 63 Thermal Properties of Polymers at the Micro Scale ..... 65 Mechanical Properties of Micro Molded Components (Micro Tensile Test and Nano Indentation) ..... 67 Molecular Orientation and Crystallinity in Micro Molded Parts ..... 70 Amorphous Polymers ..... 71 SemiCrystalline Polymers ..... 73 Micro/Nano ...

Miniature Mechanical Fabriion Machining

We use a range of equipment that is specifically geared for machining and fabriing minute details on microscale workpieces. Featuring 4axis machining motion, our micro CNC milling and turning equipment can handle parts as small as .005″ in diameter. Precision Components include but not limited to: Optical, Lenses, Collimators, Ferrules, Fiber Optic, Medical Devices. Microscopes and ...

Molds In Miniature | Modern Machine Shop

· He describes some of the features that allow the Kern machine to use microscale milling and drilling tools effectively. Part of the success results from large mass, he says. A special polymer concrete frame contributes to the machine's total weight of 3 metric tons. The frame not only damps vibration (damping properties are at least 800 percent better than typical machine constructions, he ...

Characterization of microscale residual stress around ...

· Moreover, in the DIC approach, the fabriion of microscale speckle patterns is complex and the speckle quality is restricted by many factors . While in the GPA approach, the microscale grating is simply fabried by FIB milling, and the grating parameters can be designed to adapt to different measurement requirements. The relevant research including grating fabriion and accuracy ...

Latest Posts

- حجم مختلف من الفحم نحصل عليه بعد الفرز

- وحدة كسارة جديدة بترخيص

- السماد سحق آلة مصنعين في ولاية ماهاراشترا

- مقاولو تكسير الصخور المتحركة

- الصين آلة الذهب المنتج الجزائر

- سياسات البناء لسرقة المعدات

- تشغيل محطة كسارة

- آلات طحن الحجر العراق

- آلة طحن حجر خام طاحونة مسحوق الصخور

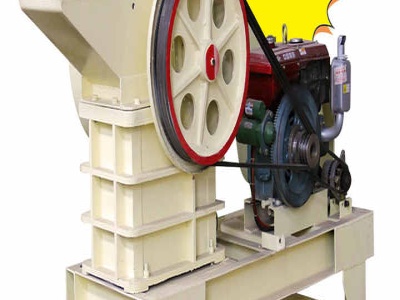

- خصائص كسارة الفك

- empresas ص سينجابورا

- بيع كسارة خام الذهب

- يستخدم المسمار معدات غسل الرمال

- شعارات شركة المحجر

- كسارة ماهالاكسيمي kolhapur

- And Grinding Flow Diagrams In Fertilizer Manufacture

- Latest Type Rock Crusher

- Stone Quarry North Olmsted Ohio

- Gold Processing Chemicals Materials

- Jfe Tc Approved Mill China

- I Need A Used Mobile Stone Crusher

- Beatty Cooper Tub Hand Washer

- Double Impeller Mining Mi Ing Agitation Tank Equipment

- Mesin Surprise Grinding

- Hammer Mill Crusher For Gold

- Gypsum Powder Myanmar

- Crushing Plant Designlayout

- Floor Tile Sale In Sri Lanka

- Animation Of Hammer Mill

- Zeniths Coal Crushing And Screening Machine