Reduction With Ball Mill

Size reduction

Mills with size reduction media: Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase. The design applied here is mainly a ball mill with an agitator, the movement of the ...

AENG 252 :: Lecture 09 :: SIZE REDUCTION – EQUIPMENT FOR ...

Size reduction is achieved by impact of the balls when they drop from near the top of the shell; Energy consumed in lifting the balls is utilized for grinding job; When the ball mill is rotated, the balls are carried by the mill wall nearly to the top; Balls are released by the gravitational pull and drop to the bottom and picked up again

Chapter 10 Particle Size Reduction

Chapter 10 Particle Size Reduction Introduction To create particles in a certain size and shape To increase the surface area available for next process To liberate valuable minerals held within particles * Size reduction process : extremely energyintensive 5 % of all electricity generated is used in size reduction

Practical 1 : Ball Milling | TF Lab 1

· In ball mill, size reduction is done by both impact and attrition of particles. Rod mill is similar to ball mills but it uses long rods for grinding media. Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks. SAG (SemiAutogenous Grinding) ...

A BallonBlock ImpactSpalling Wear Test and Results on ...

Ballonblock impact wear testing mchine ... milling and grinding operations where breakage and spalling are prob lems. ... and ways to reduce wear losses, especial ly of strategic and critical metals such as chromium, manganese, and cobalt.

Ball Mill Working Principle And Main Parts

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes. The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small .

Ball Mill Size Reduction

ball mill introduction. ball mill an example of grinder is an efficient tool for size reduction of solid through grinding for many appliions in chemical means sub dividing the solids to a finer product than crushing. principle ball mill works on the principle of impact that is the size reduction of the solids is done by the impact. construction a ball mill consists of.

Size reduction with Planetary Ball Mills

Mixer Mills Preliminary size reduction assisting retSCH Planetary Ball Mills are used for the pulverization of soft, fibrous, hard and brittle materials. They achieve a very high final fineness down to the submicron range. The feed size depends on the mill and can be as large as 10 mm.

Reduced Neck End Mills

These ball profile end mills are engineered for excellent performance in light profiling, High Efficiency Milling (HEM), and . . . 6 Flute Corner Radius Variable Pitch Reduced Neck (Aplus) The reduced neck geometry of this variable pitch end mill with 6 flutes provides maximum strength in .

Size Reduction Equipment

3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills A primary crusher operates on run of mine material accepting anything that comes from the mine face and breaking into 150250 mm (610 in). A Secondary crusher reduces these lumps into 6 mm (1/4 in). Grinders reduce crushed feed to powders

Ball Mill Explained

Ball mills are usually designed with a maximum reduction factor/ratio of 60:1 although it is possible to achieve reduction ratios of up to 70:1. The electric drive for a ball mill should be able to handle loads where the ball mill is charged by up to 45% with balls.

Planetary Ball Mill PM 100

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

A Review of Methods for Synthesis of Al Nanoparticles ...

Mechanical milling as a solid state synthesis usually performed using ball milling equipments that generally divided to "low energy" and "high energy" egory based on the value of induced the mechanical energy to the powder mixture [13]. The objective of milling is to reduce the particle size and blending of particles in new phases.

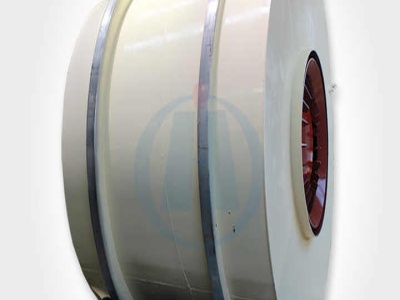

Alpine SO Super Orion Ball Mill

Ball mills are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media – in this case balls. The diameter of the balls is between one and several centimetres to suit the appliion – smaller balls for fine milling results and larger ones for coarser milling tasks.

Grinding, milling, crushing

b) Ball mills The mill consists of a slowly rotating, horizontal steel cylinder, half filled with steel balls ( – 15 cm in diameter). The final particle size depends on .

International Journal of ChemTech Research

affecting size reduction includes – feed rate, size of the screen and rotor speed. A hammer mill is typically operated between rpm. 5. Ball mill The ball mill consists of hollow cylindrical rotating shell made of steel lined with porcelain or high carbon steel plate.

Inustrial Gearboxes

Range: Power range to 55000kw, Reduction ratio range up to 650:1 Size: From 80mm to 1000mm centre distance. Type: Bevel Helical in horizontal / vertical models. Appliion: For appliions > 50kw Agitators, Conveyors, Crushers, Cranes, Larger Ball Mills, Plastic Extruders, Fin cooler drives, Kneaders, Thickeners.

Maximum size reduction in a ball mill is done by the

Maximum size reduction in a ball mill is done by the, _____ action. a) Attrition b) Compression c) Impact d) Cutting

12 Ways To Reduce Cutting Vibrations On Cnc Milling ...

Today, I've compiled 12 ways to reduce the cutting vibration of CNC milling machines in the hope that it will help you all! 01. Use sharp inserts to reduce the cutting force of CNC milling machines. Clamp inserts are divided into coated and uncoated inserts, and uncoated inserts are usually sharper than coated inserts because if the inserts ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

ball mill size reduction micrometer

ball mill size reduction micrometer. Pharmaceutical Technology: PRACTICAL I : BALL MILLING . A ball mill is an example of a comminution method which produces size reduction by both impact and attrition of particles.

Latest Posts

- محطة كسارة الحجر المحرز في مصر تكلفة

- الشركة المصنعة لآلة تصنيع رمل نهر النهر في الأردن

- تصنيع كبريتات الكالسيوم من الحجر الجيري

- آلة طحن مسحوق الكالسيت

- مزود المحمول كسارة خام الحديد الفك

- تكلفة معدات فحص خام الكروم

- مطحنة المطرقة مدفوعة بالمولد

- مورد معدات غسيل الكوارتز

- قائمة شركات الفحم في السعودية

- مصانع طحن الركام الناعم ملم

- زجاجة ماكينات الكسارة الموردين في الجزائر

- محجر الجرانيت مصنع كسارة الصخور

- تستخدم آلات الكسارة للبيع في بولندا

- شاشات للكسارات في السودان

- تصميم آلة مطحنة الكرة المطحنة

- Cme Uj440i Cone Crusher Dimensions

- Ask A Stone Crusher

- Ispolzuetsya Dobschi Masins Drobilki Dlya Prodazhi

- Cost Of Cape For Belt Conveyor Per Meters

- Complete Crushing Plant Manufacturerpany In Kazakhstan

- Gold Minining Equipments

- Magnesium Carbonate Plant Layout In Bharuch Gujarat Micronesia

- Jiaozuo Crushing Equipment

- Electric Grain Mill

- Por Le Placer Mill

- Cleaning Mining Equipment Hotsy Pacific

- Manuguru Singareni Coal Mines

- Price Pe600x900 Stone Crusher

- Mp Crusher Lube Problems

- Jaw Crusher Jaw Plate In Puerto Rico