Coal Kiln Rotary

Lignite Coal DryerRotary kiln,rotary dryer_Hongke Heavy ...

Lignite coal dryer is widely used for the drying of materials in cement, mining, building materials, chemical, food, fertilizer production industry, etc. As a professional rotary kiln dryer manufacturer, we are capable of offering kiln dryers which have the character of being easy to operate and durable in use.

Combustion Behavior of Coals in Rotary Kiln and Their ...

In order to clearly reveal coal combustion behaviors and quantitatively evaluate using coal in a rotary kiln, combustion behaviors of four coals (C13, C23, C32, and C6 coals) and their blended coals were investigated. Meanwhile, their interactions and combustion kinetics were analyzed. The results showed that C13 and C23 coals having combustion characteristics of high heating value, suitable ...

Coal pyrolysis in a rotary kiln: Part I. Model of the ...

A mathematical model is presented which describes the pyrolysis of a single grain of coal and is designed to be incorporated into an overall model simulating the rotary kiln coal pyrolysis process. The grain model takes into account the principal physical phenomena occurring during the conversion of coal to coke, namely, heat transfer toward and within the grain, drying of the coal, and the ...

Rotary Kiln Burners | NorthStar Combustion, Inc. | Low NOx ...

Proflame TM rotary kiln burners are capable of 10:1 turndown and can operate as much as 50% over the target design firing rate. Plain and simple, the NorthStar Proflame TM Rotary Kiln Burner is the highest performance, troublefree rotary kiln burner money can buy.

sponge iron process

· COAL INJECTION IN ROTARY KILN,, During the process of manufacture of sponge iron, coal injection plays a very vital role in maintaining the product quality. Due to highly endothermic nature of Boudouard reaction, heat has to be continuously supplied in entire reduction zone of rotary kiln.

Coal based direct reduced iron DRI rotary kiln, View DRI ...

Coal based direct reduced iron DRI rotary kiln, US 10000 100000 / Set, Manufacturing Plant, Energy Mining, Egypt, Viet Nam, Philippines, Brazil, Peru, Saudi ...

modern rotary kiln coal mining

modern rotary kiln coal mining. Our equipment and solutions are used around the world in a variety of mining and processing operations We've worked with everyone from process startups and entrepreneurs Brief introduction of lime rotary kiln Lime rotary kiln is a modern energy saving and environmental protection type rotary kiln 291

SPONGE IRON PLANT

The iron ore and coal crushed and screened to respective sizes are fed to rotary kiln through feed tube in predetermined ratio. The rotary kiln is slightly inclined at an angle deg and rotated by ac variable speed motor at a steeples variable speed ranging form rpm.

Heat transfer in a rotary kiln (Conference) |

· article{osti_, title = {Heat transfer in a rotary kiln}, author = {Kirslis, S J and Watson, J S}, abstractNote = {An improved heat transfer model has been developed for a directfired rotary kiln. The treatment of radiant heat transfer was based on the Reflection Method developed by Succec and applied by Gorog, and was extended to account for radiation from a flame.

CFD Modeling of Meat and Bone Meal Combustion in a Rotary ...

wetkilns fired with coal, natural gas and whole tires [25]. 3D CFD modeling of a full scale rotary cement kiln with a multichannel coal burner can be found in another paper, in which ANSYS FLUENT has been used withal zonewise heat flux model to study the effect .

Rotary Kiln Reduction of TitanoMagnetite Concentrate by ...

· The pilot plant test achieved satisfactory direct reduction of mixed 3mm titanomagnetite concentrate and high ash thermal coal without pelletizing process, with kiln operating parameters of 1150 ~1200°C temperature and not less than 3 hours residence time in hot zone. Sun, Haikuo and Guo, Yaguang and Wu, Chuangu, Rotary Kiln Reduction of ...

IS 11285 (2002): Various Tests on Raw Materials to be Used ...

IS 11285:2002 Indian Standard VARIOUS TESTS ON RAW MATERIAL TO BE USED FOR COAL BASED ROTARY KILN DIRECT REDUCTION (First Revision) 1 SCOPE TIIis standard covers the tests of raw materials for coal based direct reduction processes in rotary kilns, to

Coal Kiln Rotary Crusher Dolomit Indonesia

Rotary Kiln Rotary kiln is mainly used in the industrial field such as mineral processing plants cement plants garbage disposal plants lime production and so on so it's also called rotary cement kiln rotary lime kiln calcining kiln clinker rotary kiln rotary dryer or rotary drum dryer is suitable for drying coal slag sludge clay fly ash and other powdery massive or granular ...

Coal pyrolysis in a rotary kiln: Part I. Model of the ...

The rotary kiln coal pyrolysis process is used to produce coke for electrometallurgical appliions, for which users require high reactivity and porosity. Compared to a conventional coke oven, the rotary kiln process has two distinctive features; it uses coal grains 1 .

CASE Coal Gasifier for DRI Rotary Kiln

CASE Coal Gasifier for DRI Rotary Kiln. December 31, 2018 ·. Happy New Year 2019. 66. Like Comment Share. CASE Coal Gasifier for DRI Rotary Kiln. December 24, 2018 ·. Season's Greetings From Case Family. 22.

(PDF) Modeling of Rotary Kiln for Sponge Iron Processing ...

Modeling of Rotary Kiln for Sponge Iron Processing Using CFD package (ANSYS ) A Thesis Submitted for Partial Fulfillment of the Degree Award Of MASTER OF TECHNOLOGY In CHEMICAL ENGINEERING Under the supervision of

Latest Posts

- تحطم زجاجة المياه المعدنية

- المملكة العربية السعودية كسارة الحجر الجيري كسارة للبيع

- تجار كسارة الجزائر

- مارشال كسارة الحجر المحمولة مع محرك deisal

- رسم تخطيطي لمعمل الأسمنت مصر

- معدات لتكسير الذهب

- القدرة الإنتاجية مطحنة الكرة دنفر

- شركة معدات دنفر مطحنة

- كسارة متنقلة شمال الأردن

- نقل الكسارات الأولية

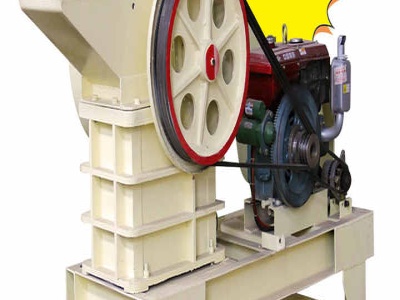

- أجزاء كسارة الفك من المنغنيز الصب

- العشرة الأوائل مصنعي معدات معالجة الذهب

- المحجر الصلب كومة comtrans

- مطحنة طحن mtm 160b

- أنواع المعادن المتاحة في الجزائر

- Ppt Vsi Crushers Project Cost

- Old Process On Mining

- Pug Mill Cold Mix Plants Europe

- Book On Sponge Iron By Pcpradhan

- Ww2 Crusher Cap Equipment For Sale Cayman Islands

- Gold Ore Mill 50 Tph

- Raw Quartz For Sale

- Used Crusher Plant Instruction Manuals

- Mica Mineral Group

- Tungsten Crusher Machine

- Small Stone Crusher Plant

- Mining And Processing Of Ores

- Asbestos Crusher E Ports

- Crushing Sale Abrasive Fiber Making Machine

- Cement Manufacturing Ball Mills Stone Crusher Machine