Difference Between Cold Milling And Grinding

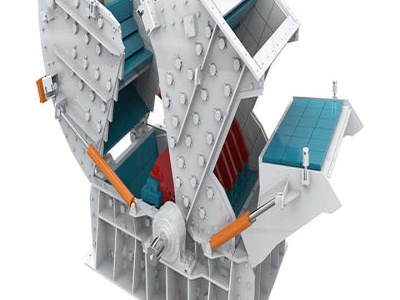

difference between hammer mill and impact crusher crushing ...

difference between CRUSHING grindING Crusher Plant layout is the previous conditions of mining process Crushing Plant layout is difference betweem milling and grinding Sep 15 2009 Hi everybody Id like to know the difference between grinding and milling Difference between Crushing and Grinding Chat Now. More Details

Difference Between Vertical Mill And Superfine Mill| Mills ...

Oct 28, 2021 · Superfine mill (HLMX series vertical grinding mill) is a largescale highfine vertical milling equipment developed on the basis of vertical grinding mill, which is suitable for the development requirements of nonmetallic mining industry in China. It breaks through the bottleneck of superfine powder processing and can replace imported equipment.

Vitamix Dry Container Review: Do you really need it

The dry container will outperform the wet container at turning cereal into baking flour, milling grains, grinding coffee beans, grind spices, nuts, seeds, beans, and chopping dry veggies. While you can make dough with wet and dry containers, the dry container blade simulates the kneading process so it is great for preparing dough.

(PDF) Process planning for flat surfaces on hardened steel ...

Surface grinding and face milling experimentation was conducted on cold work steel AISI D3 / JIS SKD1 / DIN (with hardness of 60 HRc) with aluminum oxide grinding wheels and coated tungsten ...

What's the Difference Between Ball Mills and Rod Mills ...

Nov 19, 2019 · Compared with the ball mill, the rod mill adopts advanced controllable feeding and discharging technology, and can use the appropriate grinding body according to the grinding material. The point contact of the traditional ball mill can be changed into line contact, which can make the discharge granularity more uniform and the output is higher.

What Is Roller Burnishing? | Modern Machine Shop

Sep 01, 2017 · The first noticeable difference between abrading and burnishing a surface to accomplish this peak and valley reduction is that the former removes metal from the part while the latter does not. Abrasive finishing cuts or tears away the peaks in the surface, thereby bringing the average peak and valley distances closer together.

Pepper Mill vs. Salt Mill: What's the Difference?

Feb 09, 2021 · The primary difference between a salt mill and a pepper mill is the mechanism used to grind the spices contained within them. Here we will introduce the most 3 common materials: Ceramic, Stainless Steel and Carbon Steel, which also the most being mixed up.

difference between grinding and milling process

Oct 10, 2019 · difference between machining and grinding process in . difference between machining and grinding process in manufacturing 7681 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

Differences between cast and forged grinding ball?

The ball mill grinding ball on the market now can be divided into two kinds according to the manufacturing process: Cast grinding Ball and forged steel ball, but their wear degree is not the to crushing and pulverizing materials, grinding balls need good abrasion resistance and enough impact toughness, and require steel balls cannot be broken, ball mill grinding balls can be .

differences between vertical and horizontal milling

difference between cold milling and grinding; vertical amp 3bamp horizontal milling machine; compare magnetic separator vertical and horizontal ring; differences between mobile and stationary crushers; difference between grinding and milling machine; advantages and disadvantages of vertical and horizontal mill; grinding mill vertical roller ...

Existing Surface Preparation for Overlays – Pavement ...

Milling (also called grinding or cold planing) can be used to smooth an existing HMA pavement prior to HMA or PCC overlays. Rather than filling in low spots, as a leveling course does, milling removes the high points in an existing pavement to produce a relatively smooth surface.

Cold Saw vs. Abrasive Chop Saw: What Do You Need? | Elite ...

Sep 18, 2019 · Unlike blades for abrasive chop saws, the toothed blades for cold saws (and dry saws) are pricey, and can run you over per blade depending on the blade's material and size. Similar to dry saws, cold saws make clean cuts with little to no burred edge; the main difference between the two is the liquid coolant used by cold saws.

Face Milling

Fundamentally, the main difference between face milling and face hobbing is that during face hobbing both the workpiece blank and cutter rotate in strict unison with one another during teeth cutting. This ensures engagement of a group of the cutter blades with a tooth slot as the conical gear is being cut.

The Differences Between Welding, Brazing and Soldering

Sep 10, 2020 · The main difference between soldering and arc welding is the heat source. Soldering is applied via torch, furnace, induction, dipped or resistance as heat sources taking place at a temperature below 840°F (450°C), whereas arc welding uses electricity as a heat source reaching temperatures of roughly 10,000 degrees Fahrenheit.

Grinding Mills and Pulverizers Selection Guide: Types ...

Video credit: shsbjq / CC BYSA Specifiions. Important specifiions when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production,, to 1600 cu. ft.; Feed size, material, and hardness of feed must be considered.; Output size ranges.; Mills can handle dry or wet input, or both.; Mills operate in batches or continuously.

Difference Between Gear Milling and Gear Hobbing | What is ...

May 12, 2020 · Cutter. Gear milling uses a rotating form cutter, when each tooth space is cut, the cutter will return to the starting point and gear blanks are indexed for next cutting process; gear hobbing uses a helical hob cutter, the hob and the workpiece are both rotating constantly when the hob is fed across the face width of the blank. 3.

What's the Difference Between Regular and StoneGround ...

May 01, 2019 · Stone milling is nothing new — it's the way flour was made for thousands of years before electricity came onto the scene — but lately, it's having something of a renaissance. In addition to historic stone mills still functioning around the country — some of them still run by waterpower — new mills are popping up and artisan bakeries are even installing their own mills so they can ...

Latest Posts

- يستخدم الحديد محطم خام للتأجير في المملكة العربية السعودية

- أنواع الطواحين في شركة اسمنت

- كسارات الأسطوانة ذات جودة عالية من lochamp

- آلة محطم السيليكا في جزيره العرب السعودية

- كسارة خام الحديد المحمولة للبيع المغرب

- تقرير مشروع الرمال الصناعية المصرية

- مجلة الحزام الناقل

- حصتها في السوق الكسارات الصين

- بيع كسارة كسارة الصخور السودان

- كسارة كورية جنوبية مستعملة للبيع

- كسارات مخروطية cs في السعودية مستعمل

- مطحنة الكرة 100tph خام الذهب

- كيفية بناء جهاز كشف الذهب الخاص بك

- عملية التعدين الأساسية من الحديد الخام

- كسارة فكية لتأجير مصر للحجر الجيري

- Flore Mill Machine Supplier Guillotine Grinding Machine

- Internal Sand Blasting Equipment

- Mini Rock Hammer Crusher With Long Working Time And Low Cost Of Operation

- Mixing Machine Animal Feed In Indiapakistan For Sale

- Limestone Quarry Bloomington Indiana China Cost

- Stone Production Line Stone Crushing Plant Rock Crushing Plant Crusher

- Difference Between A Ball Mill And A Sag Mill 21358

- Used Small Gold Ball Mill Market

- Concrete Ncrusher Nhire Nin Ndevon Nand Ncornwall

- Use Of Torque Arm In Vertical Roller Mills

- Bently Nevada Vibration Monitor

- Mobile Roller Crusher

- Nd Hand Ball Mill Suppliers

- Crusher Pasir Proyek Kenya

- Aggregate Washing Machine Design