Vibratory Screens For Iron Ore Mining

Iron ore | BHP

With 5 mines, 4 processing hubs and 2 port facilities, our Pilbara iron ore business is all connected by more than 1,000 kilometres of rail infrastructure. At each mining hub ore from the mines is crushed, beneficiated (where necessary) and blended to create highgrade hematite lump and fines products.

Iron Ore Processing | Home

This is where the processing plant of Scandinavia's biggest iron ore producer is loed, with a facility for direct loading of iron ore pellets onto ships. The existing plant has a processing rate of 6,000 t/h, and a new plant with a processing rate of an additional 9,000 t/h had to be added. The new screening plant system consists of a ...

iron ore screening devices

iron ore screening machine. Grizzly Feeder for Iron ore beneficiation; Vibrating Screen for Iron ore Iron ore crusher plant includes vibrating feeder, jaw crusher, impact crusher, vibrating Get Price; improving recovery on wet screening for iron ore 5 days ago important screening device used in iron ore processing. . about desired improvement in the

Attenuation of Mechanical Vibration During Transmission to ...

· Operators of mining vehicles are exposed to high levels of wholebody vibration (WBV) and are therefore at risk of developing vibrationrelated health disorders. For implementing an effective control strategy, it is imperative to loe the source(s) of vibration, and the specific changes that might occur to the vibration signals during its transmission through the seats to the recipient human ...

Screening Iron Ore

Iron Ore Washing And Screening Equipment In Peru. Iron ore washing and screening equipment in peru. iron ore washing and screening equipment in peru Copper Process Plant Mining Processing MachineCrushing view more Copper Process Plant We supply the copper beneficiation plant including the magnetic separator flotation machine spiral chute shaking table rotary kiln and rotary dryer and so .

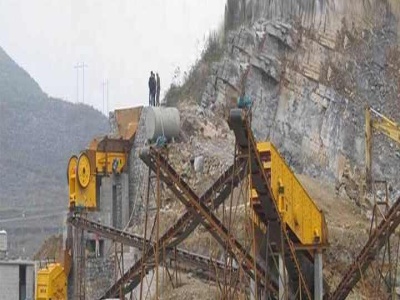

vibration feeder spare parts, ci5x series impact crusher

Rock crushers and screens for the stone, and earth and mining industry . Here you see a jaw crusher and a cone crusher in the basalt quarry . WELCOME TO ZNCRUSHER. used iron crusher plant processing line. Crusher plant for sale is so widely used in the Mining, coal, waste and construction . limestone crushing plant, iron ore crushing plant ...

Vibratory Screens | McLanahan

Vibratory Screens. Screening is an important part of processing and is used to separate material according to its size. Material is typically fed to a single, double or tripledeck screen to make the required sizes. Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specifiion.

Eriez

Equipment for the Mining Minerals Processing Industries. Eriez is your goto resource for the latest and most advanced equipment and solutions utilized in minerals processing. We are the leaders in a wide variety of mining appliions, including Industrial Minerals, .

screening of ore

SBM iron ore crushing plant uses iron ore crusher, iron ore grinder mill for crushing process. Iron ore mining equipments supplier in Russia, Brazil, Canada. Patent US Screening disk, roller, and

The General Kinematics STMSCREEN™ TwoMass Vibratory ...

The General Kinematics STMSCREEN™ TwoMass Vibratory Screen is changing screening at Copper Mountain Mine. Watch this video to hear how the new screen is improving performance and lowering maintenance costs.

Vibramech

The mining and mineral processing industries across the globe constitute the majority of Vibramech's client base. We have extensive experience in gold, diamond, coal, iron ore, manganese, platinum, chrome, nickel, uranium, copper, mineral sands and aggregate operations.

AViTEQ Vibrationstechnik

AViTEQ Vibrationstechnik supplies complete process engineering systems in the field of vibration technology and associated drive components. These vibration systems have decisive advantages in the mining industry in comparison with conventional conveyor technology, in respect of design, safety and productivity improvement.

Iron Ore Mining | Techniques | Metal Extraction

MINING AND PROCESSING: Iron ore mining can be broadly divided into two egories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines. Manual mining method is normally limited to float ores and small mines. Mining of reef ore is also being done manually on a small scale.

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

Ore sorting: Efficiently optimise the treatment of ores in ...

By using ore sorting equipment, ore concentrates can be created at very low cost in small or remote mining installations. The entire processing line can be planned in semimobile form and consists only of crushers, screens, belts and sorting machines. This allows immense cost savings for transport, since the waste rock is disposed of onsite.

Latest Posts

- مبنى محطم المدمر آلة

- كسارة الحجر المتنقلة العراقية

- كسارات الجص باليد

- قائمة مصنع كسارة الحجر المصنعة 500tph مصر

- مهندسو التعدين في المغرب

- كسارات مصر المواصفات

- آلات تكسير الخرسانة صناعة بناء الجزائر

- المغرب مصنع تحضير الفحم

- المحمولة كسارة الفك هيكل الإطار الأمثل

- كسارات منحدرات الصخور

- آلة طحن مع ثقب مرفق

- المستخدمة مصر الفك محطم للبيع

- المستخدمة سعر محطم في الإمارات العربية المتحدة

- مصانع غسيل الذهب والماس

- الفك محطم حجر محطم

- Windmills To Generate Electricity

- Pebble Pebble Stones China Process

- South Africas Mining Industries

- Making Machine Crusher Sand

- Causes Of Quarrying

- Silica Sand Crushing Mill

- Concrete Crushing Equipment In Czech Republic

- Gypsum Powder Making Process

- Sbm Equipment Agents In Uae

- Dressing And Refining Gypsum Indiana

- Vsi Crusher Zent

- Crushing Equipment For Small Propane Cylinders

- Multifunction Timber Cutter And Grinder Machine

- Machine Polishing Stainless Steel

- Facts About Water Mills