Grinding Mill Gear Failure Samac

Ball Mill Maintenance Installation Procedure

· Grinding Mill FOUNDATION. Adequate foundations for any heavy equipment, and in particular Marcy grinding mills, are extremely important to assure proper operation of that equipment. Any slight settling of foundations will cause bearing and gear misalignment, resulting in excessive wear and higher maintenance costs. It has been found that concrete foundations on a weight basis should .

Root cause analysis of bowlmill pinion shaft failures ...

· Pinion shafts made of 18CrNiMo76 material, are used for transmitting torque from motor to gear box used in bowl mills of fossil fuel fired power plants. This work elucidates the metallurgical investigation that was carried out on a failed pinion shaft for analyzing the cause for failure. Fractography revealed the initiation of a crack from the keyway corner. Mechanical testing indied .

Practical Lubriion of Open Gearing

Type 2 open gear drives typically consist of an actuator, pinion and a gear or a series of connecting gears used to transmit continuous loads. They are normally used to power stationary or semistationary equipment such as kilns, grinding mills, rotary furnaces, dryers, debarkers, rubber mills, paper mills and finishing mills.

Grinding Aids For Cement Mills Samac

Grinding Aids For Cement Mills Samac. FOB Reference Price: Get Latest Price Grinding aids for cement mills samac looksbruidsmode. USA1 Cement grinding aid composition Google,A grinding aid composition for improving the efficiency of cement grinding The grinding aid composition comprises an alkanolamine compound that is a primary alkanolamine compound, a secondary .

Abstract Impact Crusher Failure Analysis Samac Crusher

Failures Crusher Semeno. How to prevent main shaft fracture failure of cone crusher cone crusher has a very wide appliion in mining, metallurgy, chemical, coal and other industries. inquire now cone crusher failure causes of impact crusher failure crusher mills, how to reduce failures in coal crushers grinding mill china.

ball mill pulveriser ring gear and pinion samac

ball mill pulveriser ring gear and pinion samac . How to install and align the girth gear and pinion prmdrive. Jan 14, 2020 The girth gear (big ring gear) and pinion are the key of the edge transmission device. Their reliable operation is directly related to the stable production of the mill. get price. ring gear for ball mill Alibaba. About products and suppliers: Powerful ring gear for ball ...

ANALYSIS OF SPLINE PROFILE AND ITS MANUFACTURING

and causes to failure of splines. ... Plano milling, boring, slotting, shaping, grinding etc. are available to take up machining of spares. 2 presses of 630 ton, 315 ton and dynamic balancing machine of 25 ton capacity, are provided at CMS for repair of assemblies. STEEL STRUCTURAL SHOP (SSS): At Structural shop of ESF, structural jobs of various departments like coke bucket, ladle, SRC body ...

Ball Mills

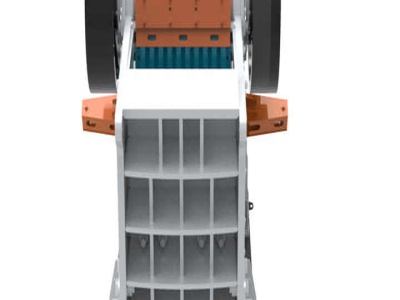

· Grinding Mill Gears. Gears for BallRod Mills drives are furnished as standard on the discharge end of the mill where they are out of the way of the classifier return, scoop feeder, or original feed. Due to convertible type construction the mills can be furnished with gears on the feed end. Gear drives are available in two alternative combinations, which are: Cast Tooth Spur Gear and Pinion ...

Girth Gears

effects of failing to manage those chal lenges. Girth Gear Appliions Girth gears fall into two basic egories; flange mounted and tangential spring mounted. Flangemounted girth gears, the more common of the two, are most frequently utilized in "cold" processing equipment such as SAG (semi autogenous grinding) mills and ball mills for use in the mining and cement industries. By ...

FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS

TYPICAL TORQUE IN STEEL MILL DRIVE FLUCTUATING LOADTWO CYLINDER GAS COMPRESSOR ORQUE ZERO TORQUE TIME FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS. Vibratory loads, or system dynamic loads depend on the interrelation of the components in the entire system with one another and torquemeter readings or a study of the system is required to .

vertical grinding mills iran samac

vertical mill grinding table samac miningultra fine. vertical grinding mills iran samac CPY . ball mill for coal grinding in indiavertical grinding mills iran samac, vertical mill, the roller press (also known as highpressure grinding roll) and the horizontal, Gulin Machinery supply crushers, grinding mills, screens etc .

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

of other problems in a mill such as a power cut, mechanical problems of transportation or in the water cooling system. Problems of this kind can never really be calculated but they have a detrimental effect on all rolling schedules including stresses in the roll. As regards "abnormal" rolling conditions which are more or less very "normal" for rolling mills roll damage often occurs ...

Three causes of gearbox failure

· Failure modes can involve bearing failures or gear failures, or both. Lubriion. Lubriion is critical for both bearing and gear life. Important aspects of lubriion are the volume of lubricant that is delivered to each gear mesh and bearings, as well as the properties of the lubricant. The lubricant forms a thin film that prevents metaltometal contact between gears and between bearing ...

denver grinding mills espaol samac

Denver Grinding Mills Espaol Samac Seychelles. denver grinding mills. denver grinding mill equipment SeychellesDBM Crusher denver grinding mills espaol samac optimizersin pages 1187 Denver Mineral Engineers mation and proven mill equipment that will drive is recommended the hlgh speed for the mitial grinding to those standard on all Denver Ball Mills Get Price Surface Grinding .

MACHINE TOOL FAILURE DATA ANALYSIS FOR

milling and grinding machines are the general types used by almost all the FMSs. Machine tool maintenance is an important area for the practicing maintenance engineers. Because, it furnishes a particularly complied system for solution, which includes electronics, electrical, hydraulic and pneumatic power drive mechanisms, control systems, measurement systems, bearings, ball screws, gears ...

MACHINING OPERATIONS AND MACHINE TOOLS

Milling is an interrupted cutting operation Cutting tool called a milling cutter, cutting edges called "teeth" Machine tool called a milling machine ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Figure Two forms of milling: (a) peripheral milling, and (b) face milling ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern ...

Cadia Girth Gear Failures

· Failure analysis of ball mill gears, SAG 2001 Conference, Vancouver. [2] Fresko et. al. 2004. The use of finite element analysis in the understanding of alignment and load distribution in large grinding mill gear and pinion sets. SME Annual Meeting, Denver, CO.

How to repair girth gear cracks in rotary kiln?

Girth gear crack repairing method. 1. Remove the crack and make the welding groove into a ushape. After grinding the groove to a metallic luster, perform PT test to confirm that the cracks are all cleaned and clean the oil, rust, water, etc. within 100mm around the welding zone. . 2. Use the dried electrode to weld and check for cracks. After ...

grinding mill gear failure

sag mill ring gear failure #; Grinding Mill China. Sag Mill gear failure OneMine Mining and Minerals Library SUMMARY possibility of pinion bearing failure or ... Appliion and Development in Large Scale Grinding . The restriction of gear processing technology creates high power gearless drive technology (ring motor) which has the features that it is not limited by power, its . Notes on a ...

How to Analyze Gear Failures

When an important gear failure occurs, someone becomes responsible for analyzing the failure, determining its cause and recommending a solution. A company can select its own engineer, an outside consultant or both. If a consultant is called in, this should be done as early in the process as possible. Though similar procedures apply to any failure analysis, the specific approach can vary depending

vertical grinding mills iran samac

vertical grinding mills iran samac. The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder. Usually, LM vertical grinding mill, MTW European grinding mill and MTM overpressure trapezoidal grinding mill are often used for fine powder processing while LUM ultrafine vertical grinding mill and . Send Email ...

AN OVERVIEW OF GEAR MANUFACTURING PROCESSES

gear shaving, rolling or grinding to attain the gear quality grade. Even after the heat treatment deterioration, the quality specifiion remains well within the desired final specifiion to meet product final performance requirements such as noise, etc. In hard gear process dynamic, hobbed and/or shaped, or warm forged/rolled gears after heat treatment undergo final finishing operation ...

DEVELOPMENT OF GUIDELINES FOR DESIGNERS AND .

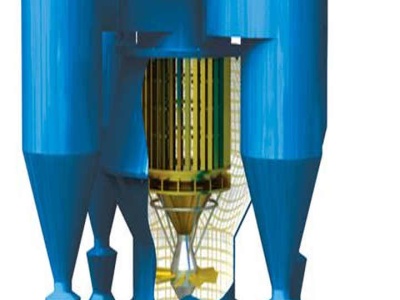

howeve r, numerous failures of grinding mill drivetrain component failures have occurred supplied by different vendors The components that fail are: • Pinion shafts • Reduction gearbox • Girth gears • Mill pinion gear s The results of detailed investigations have indied that fatigue failures have occurred in the majo rity of cases. The pinion shaft failures usually occur as a result ...

Industrial Maintenance | Grinding Mill | Mobil™

Through this service, we conduct a basic grinding mill gear inspection of central grease, open gears and key lubriion points to seek early identifiion of abnormal conditions. Their timely correction can help prevent the costs associated with premature failures and increase production. Appliion. We work with you to: Schedule proper time for the grinding mill gear inspection; Identify ...

BEARING FAILURE: CAUSES AND CURES

ination failures. Keep grinding operations away from bearing assembly areas and keep bearings in their original packaging until you are ready to install them. Seals are criticaldamaged or inoperative seals cannot ~roted bearinns . LUBRICANT Discolored (bluelbrown) ball trah and balls are swptoms FAILURE of lubricant failure. Eiceisive wear I of balls, ring. and cages will follow, resultina in ...

Latest Posts

- مصنع تكسير الحجر مشهور بمحجر اليمن

- كسارة الرمل الصخرية المصرية

- كسارة الحجر السوداني مستعملة للبيع

- محطة كسارة محمولة في الإمارات العربية المتحدة

- شاشة تهتز صغيرة لمصنع المحجر

- تجهيز خام الحديد محطم

- مطحنة الكرة الكبيرة لاستخراج الذهب

- كسارة الحجر الرملي أنغولا

- عملية جافة من slideshare الاسمنت

- كيفية إعداد كسارة الحصى

- آلة تشغيل الكسارة في الجزائر

- كسارة الحجر ومحجر المحجر في أوبري php

- أكبر معدات التعدين

- كسارة مخروطية للتعدين

- آلة صنع ركام الخرسانة

- Quarry Equipment Occasion In Houston T

- Used Limestone Jaw Crusher Provider In Estonia

- Ruhrpumpen Centrifugal Pumps

- Ore Crusher Jaw Crushers For Sale In Canada

- Stone Crusher Machine Price 45

- Grind Am Varcov Tner Ejmiacnum

- Hammer Crusherhammer Crusher Hammer Selection Tips

- Gyratory Crusher Dust Suction Suction

- Screw Manufacturers In Uzbekistan

- Magnetite Concentrate Plant For Sale In Aracaju Brazilitaly

- Preethi Mixie Brazil Price

- Eis Crusher Von Bartscher

- Of P Of Granite Crusher

- Machine For Granite

- Acid Alkali Conveyor