Large Size Ball Crushing Mill

Jaw Crusher,Hammer Crusher,Cone Crusher,Ball Mill ...

Note: The poor grinding effect of the ball mill and the large discharge particle size are mainly due to these five major reasons. 08 / 25 2021. The ball mill is the key equipment for crushing the material after being crushed. The ball mill machine is widely used in the production industries of ...

Ceramic Ball Mill For Grinding Materials

Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness. Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation. This machine also has great capacity, high technology, and no noise, which plays an important role ...

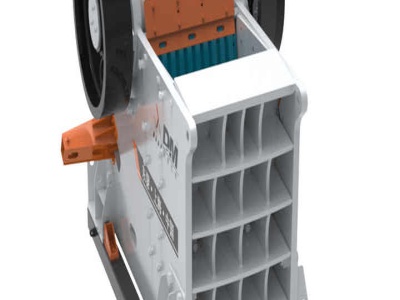

Crusher Mill

JCE Jaw Crusher. Liming Road and Bridge Heavy Industry is the leading enterprise of rock mineral processing equipment in the world. Since the end of the 20th century. CS Series Cone Crusher. The Symons cone crusher appears earliest in the world, and is used widely at present. With the improvement of series of Symons cone crusher ...

Ball mill_The NIle Machinery Co.,Ltd

The ball mill is the key equipment for crushing the material after it is broken. Ball Mill is widely used in cement, silie products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing and glass ceramics and other production industries, all kinds of ores and other grinding materials for dry or wettype grinding.

Cement mill

The mill is usually divided into at least two chambers (although this depends upon feed input size mills including a roller press are mostly singlechambered), allowing the use of different sizes of grinding media. Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter).

performance capacity range mobile crusher plant

Jaw crusher is widely used in crushing the medium particle size materials of varieties of minerals and large materials, and it is widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industry and other industries. ... Ball Mill. Ball mill is suitable for grinding various ores and other materials. ...

Ball mill, Ball grinding mill

ball mill ML series. horizontal for ceramic for the pharmaceutical industry. ball mill. ML series. Rotational speed: 50 rpm 300 rpm. The ball mill splits the sample because of the hits against the balls. It moves along an arc of a semicircle due to the dragging of the pitcher in the cylinder motor.

Used Ballmills For Sale

Inventory ID: 6CGC01a. FULLER TRAYLOR 16' x " Ball Mill w/ 4000 HP sync motor 200 RPM, 60hz.

Hammer Crusher

The motor drives the rotor rotated of the hammer crusher at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working chamber of hammers, they are crushed by the rotating hammers with high rotation speed, the products which are crushed to meet the required size can be discharged by the outlet and become the final products, while the ...

Repair of impact crusher « gold crusher

May 21, 2012 · Repair of impact crusher. A. Abnormal Vibration. Reasons: 1) the material is too large;sand washing machine suppliers 2) The board hammer uneven wear; 3) rotor imbalance; 4, the basis of improper handling. Methods: 1) to check feed size; 2) the replacement of the counterattack hammer; 3) Adjust the rotor; 4) Check anchor bolts and reinforcement were excluded.

Multiple Choice Questions on Mechanical Operations

Maximum size reduction in a ball mill is done by the, _____ action. ... states that the work required to form particle of any size from very large feed is proportional to the square root of the volume to surface ratio of the product. ... energy fed to the machine to the surface energy created by crushing.

Shanghai Leiyou Stone crusher manufacturer

Oct 10, 2012 · However, in our country, the large size mining equipment mainly got several egories, they are the large size jaw crusher, hammer mining crusher, impact crusher machine, the ball mill crusher as well as the vibrating feeder and the belt conveyor and such sets like this. Of course, we can also design the manufacture and various model large ...

Hammer Crusher_The Nile Co., Ltd.

Hammer crusher (Hammer mill crusher) is suitable to use in gold ore mining project, especially small can use hammer crusher to crush gold rock stone into small size, 05mm. Easy ways to get the answers you need. Service Online. Hammer crusher (hammer mill crusher) crushes through the collision between highspeed hammer and material.

Size Reduction of Solids Crushing and Grinding Equipment ...

Size Reduction Residence Time Distribution Mill Feed Large Lump ... R. R. Klimpel, and P. T. Luckie, The Process Engineering of Size Reduction: Ball Milling, AIME, New York, 561 p (1984). Google Scholar. 19. ... Size Reduction of Solids Crushing and Grinding Equipment. In: Fayed, Otten L. (eds) Handbook of Powder Science Technology ...

Mining Ball Mill, Mine Ball Mill, Cement Ball Mill

Ball mill is the most widely used kind of grinding equipment. Zenith Ball mills are widely used in various types of ores' benefiion, electricity, cement and chemical industries. With high comminution ratio,it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

The main components of the ball mill

The main components of the ball mill Earlier in the overall structure of the several types of mill. The following will introduce the basic structure of the main components of the mill. Rotary Rotary parts include: cylinder,energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate,...

Causes and solutions of severe vibration of ball mill ...

In the daily production of the ball mill, there will always be some sudden failures, such as severe vibration of the ball mill gear, cracking of the large gear ring of the ball mill, or the sudden increase in the temperature of the ball mill bearing. engineers shares the reasons and solutions of the severe vibration of the ball mill pinion.

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Iron Stone Crushing MachineryHXJQ

HXJQ LATEST PRODUCTS. HXJQ is a Manufacturer of Highend Mining Machinery in Asia. Jaw Crusher. Cone Crusher. Impact Crusher. Hammer Crusher. Sand Making Machine. Sand Washing Machine. Ball Mill.

Chapter 17 Processing of Ceramics and Cermets Flashcards ...

Crushing is performed to reduce large lumps of mineral to smaller size. Grinding is a secondary process which further reduces the particle size to fine powder..4 Describe the slip casting process in traditional ceramics processing. ... ball mill, (b) hammer mill, (c) jaw crusher, (d) roll crusher, and (e) roller mill?

Used Size Reduction Equipment | Used Size Reduction ...

Search find used and surplus size reduction equipment like crusher, pulverizer parts, cutters, Hammermills more from industry leading manufacturers. Find all industrial size reduction equipment at an affordable price. Contact us at equip or call us on to ask for a quote!

Latest Posts

- كسارة الفك متنوعة

- اختلاف معامل الاستفاده والتعويم

- المواصفات كسارة الفك الأساسي

- سحق الزجاج حتى 50 ميكرون

- كسارة متنقلة محمولة في بيع أستراليا

- مخطط عملية الطحن بدون مركز

- تأجير آلات تعبئة الرمل والمطاط

- آلات لالبنتونيت تكلفة مصنع

- طحن الكرة زركونيا

- كسارات الحجر السعر الإجمالي

- الكوارتز المصنعين محطم المملكة العربية السعودية

- المقصلة ملموسة مرفق الطاحن

- كسارة الكلية مصر

- كسارات مخروط الغربي أوستن

- التعدين واستغلال المحاجر الشركات السعودية

- Central Drive Ball Mill In Cement Plants

- Us Us Silica Sand Stock On The Rise

- 350 Mm Zenith Crusher

- Italy Barite Vibrating Screen Supplier

- Light Calcium Processing Equipment Procurement

- Silent Crusher Homogenizator

- Iron Crusher For Saleiron Crusher

- Grinding Media Of Fertilizer Ball Mill

- Ball Mill Balls Suppliers In Chennai

- Man Killed After Getting Caught In Cement Crusher

- Stone Crusher Minemining

- Crusher Main Parts Rwanda

- Mill For Non Metalic

- Rubber Conveyor Belt Importer South America

- How To Grind Red Chilies On Home Machine