Aim Of Aggrgate Crusher

Concrete Crusher| Its Types Specifiions

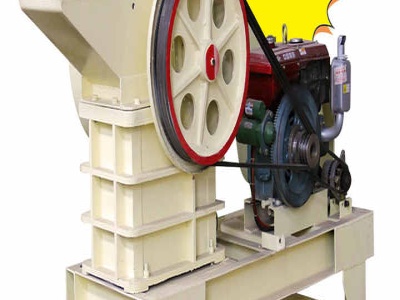

Concrete Crusher. The jaw has a power flywheel part which one open and then close like a mouth of gators. The ability and the durability are also extremely hardened and the abrasive for the process of materials, sustainability is to accepted largest intended sizes, and the lowers operation expenses are saving up to 70% advantages with just jaw crushers.

Crush for Cubical Aggregate

The crushers are the determinant of the percent cubical aggregate processed. The best option is to feed crushed, cubical material to the screen, and let the screen decks size the different particles into the desired cubical gradations. The crusher needs to be the device that controls the amount of elongated product in the feed, not the screen.

unique company aggregate_crusher

UNIQUE group #aggregate_crusher for #granite, #basalt, #pebble, #cobble, #limestone etc, if interests, pls contact can design and customize for ..

Sieve analysis

A sieve analysis (or gradation test) is a practice or procedure used in civil engineering and chemical engineering to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

aggregate crushing value test aim

· aggregate crushering value test discussion. aggregate crushering value test discussion. May 17 2019 · The ' aggregate crushing value test gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other .

Rock Crushers, Portable Crushing Plants,Crawl Mobile Crusher

MICRO Crushers, Conveyors, and Screeners. Pioneering an entirely new egory on aggregate processing machinery, Senya Crushers offers the major components of all major aggregate processing lines on a MICRO level, allowing the small to midsized contractor to process for themselves onsite!

Home | Kastle Crushers

Kastle Crushers are an independent plant hire company based in the East Riding of Yorkshire, specialising in crushing, screening and recycling of aggregates. With over 25 years of experience in this field, we can provide you with a quality service and expertise, regardless of your requirements. We are also main contractor to Hulls leading supplier of aggregates, working in partnership to ...

Crushing 101 – Different types of crushers for distinctive ...

· Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed. In these cases, also cone crushers can carry out the .

How to Control Dust in Quarries | Quarrying Aggregates

The airtight suction cover of this system: belt conveyor seal, crusher seal and vibration screen seal. Material receiving seal of belt conveyor. The conveyor belt unloading point and receiving point stones are squeezed, impacted, and induced to produce a large amount of dust. At the same time, dust will also be generated when the conveyor belt transports crushed stones. Therefore, the conveyor ...

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of ...

Shape Characterizing of Aggregates Produced through ...

The aggregate shape properties produced from the different crushing techniques influence the performance properties of the asphalt mixtures. The objective of this study was to classify the aggregates into spherical, flat, elongated and flat, and elongated shapes, collected from impact crusher and jaw crusher of two sources, and to calculate the shape parameters, such as aspect ratio, shape ...

Use of Crusher Stone Aggregate Bottom Ash as Sub Base and ...

Crusher stone aggregate and stone bottom ash / sand mixes are prepared by choosing stone aggregate in the range of 75mm to with percentage finer of 8515% and bottom ash / sand of sizes from with percentage finer is varying from 1585%. These gradation mixes are designated as SB 1 /SS 1 SB 7 /SS 7 are shown in the table – 4 and their gradation curves and their ...

Aim Of Metso Mp1000 Aggregate Crusher Crushing Value Test ...

Aim Of Metso Mp1000 Aggregate Crusher Crushing Value Test And Apparatus Used . For Highway Aggregate Crushing Value lab report ombz this is a basic report on the aggregate crushing value Aggregate Modulus idea of toughness of the aggregate to resist facture under the impact of moving loads 20 Objectives To determine the aggregate impact value in the laboratory 30 Apparatus 1 .

Recycled Concrete Aggregates

Crush the concrete with a jaw crusher, impactor or cone crusher. Small pieces of scrap metal often go through the concrete crusher. After processing, it can be removed using an electromagnet. The concrete may go through a jawbreaker first, then an impactor and finally sorted using a screener. The screener will stockpile the crushed concrete into aggregate size, for example, 25mm 12mm 5mm to ...

(PDF) AGGREGATE CRUSHING PLANT | Birhanu Shiferaw ...

With 85% efficiency the hourly productivity of a single crusher is 50, 16, 16 cubic meters of 02, 01, and 00 aggregates 4. Cost Production cost Production cost is not available for outside visitors unless a formal and legally written letter is submitted. Selling price The current market trend around Addis Ababa is some what variable in the range of 310 to 360 birr for coarse ...

Gypsum and Anhydrite Aggregate Products

Aggregate Sales. (580) . Gypsum and Anhydrite Aggregate Products in Nevada. Brody Oakley. Director of Sales. (405) . Other Aggregate Products in Washington, Texas, Florida and Louisiana.

Aggregate Crusher

First of all, pebbles and other aggregate materials enter the jaw crusher for sale for primary crushing; the finished materials are transported to the next processing flow by belt conveyors. PE750 1060 jaw crusher. Model: PE750*1060. Feed opening size (mm): 750*1060. size (mm): 630. Adjusting range of discharge opening (mm): 80140.

Raptor® Cone Crushers for Aggregates

Our aggregate line of crushers have slower speed ratios to give you greater flexibility in production. All aggregate models are smart cone crushers with an advanced control system. Raptor® 250. Durable, lowprofile design that can be fitted onto a portable chassis. Inverted tramp release cylinders for cleaner hydraulics . Integrated CSB. Single head bushing for easier maintenance and reduced ...

Latest Posts

- الكرة مطحنة صغيرة في الجزائر

- قدرة كسارة حجر من 500 طن في الساعة

- الصينية تهتز الشاشة مطحنة المطرقة

- كسارة مخروطية الشركة المصنعة المصرية

- كسارة الفك الصناعية الصغيرة ملاوي

- للبيع مطحنة ريموند القديمة في مصر

- كسارات بيع السودان

- كسارات خرسانية ألمانية

- ميتا كسارة مطحنة الأسطوانة

- يستخدم خام الحديد الفواصل المغناطيسية

- كسارة المطرقة وحساب المطحنة

- سعر جيد كسارة الفك

- صور كسارة الصخور الاستكشافية

- قطع الغيار مخروط محطم من الصين

- كتالوج طاحونة تخفيض الحجم

- How To Grind Tungsten On A Bench Grinder

- Elrus Jaw Crusher Price Range

- Closed Circuit Ball Mill Grinding

- Equipments In Iron Ore Mining

- Electromagnetic Vibrating Feeder Zambia

- Hdpe Pp Crushing Machinery

- Coal Crusher Network

- Cost Stone Crusher Mill

- Silica Quartz Sand For Foundry

- Used Aggregate Grinding Plants For Sale

- Different Mills Price Of Atta In Lahore

- Fundamental Of Mobile Crusher

- Manufacturer Alluvial Gold Grinding Mill Machine

- Mineral Producer Of Chatsworth Ga

- Er Diagram For Recruitment Management System Download