Discribe And E Plain Jaw Crusher

Subject: Mechanical Operation

10) Describe Construction and working of Fluid Energy mill. . 11) Describe construction and working of Jaw crusher with sketch 12) Explain : 1)Jaw crusher, 2)Ribbon blender, 3)Roll crusher 13) Derive equation for angle of nip in roll crusher. 14) What is critical speed? Derive .

Crusher

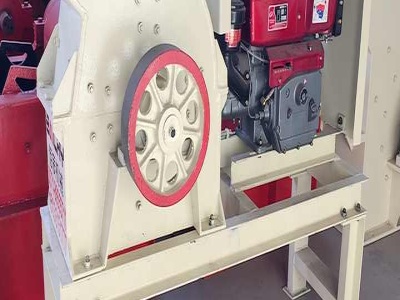

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since ...

4 Things to Know About Crushing and Screening Equipment ...

· A jaw crusher can handle soft to very hard materials and slightly wet material but not sticky. These machines use compression to break material. They are used in heavy mining, quarried materials and recycling. A gyratory crusher can handle soft to very hard materials and slightly wet but not sticky. These machines have a concave surface and a cone head, like the jaw crushers. These .

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Jaw crushers are also known as "rock breakers" and are used to break up larger, harder materials into more manageable pieces. They tend to do well with many different types of materials and don't display as much wear and tear as impactstyle rock crushers. They also produce minimal fine materials and dust, though the finished product with this type of rock crusher almost always requires ...

7 Types of Chuck Used in Lathe Machine with [Parts, Images ...

· Universal or Three Jaw Chuck. A threejaw chuck is shown in the figure. This is the most commonly used types of chuck in the lathe machine. The three jaws are generally made of highquality steel and are arrogated at an angle of 120° to each other. During the operation, the jaw teeth are made to mesh with scrawl spiral teeth (Bevel teeth). The meshing causes a moment of all three jaws either ...

Jaw Crusher: Range, Working Principle, Appliion

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece. crusher is famous product of heavy industry. An ...

How to Describe a Character's Looks Well (with Examples)

· Dynamic, wellrounded characters hook readers and drive the plot of your story. However, describing your character well can be a challenge. With a little extra work, you can ensure your descriptions will engage your reader. Start by...

Failure rate analysis of Jaw Crusher: a case study

Failure rate analysis of Jaw Crusher: a case study R S SINHA* and A K MUKHOPADHYAY Department of Mining Machinery Engineering, Indian Institute of Technology (Indian School of Mines), Dhanbad 826004, India email: ravishankarism0181 MS received 18 July 2014; revised 31 March 2016; accepted 30 October 2018; published online 2 January 2019 Abstract. Failure of crusher .

Unit 3: Chucks – Manufacturing Processes 45

Describe threejaw universal chuck. 3. Describe fourjaw universal chuck. 4. Describe Collect chuck. 5. Describe Jacobs collect chuck chuck. 6. Describe Magnetic chucks chuck. 7. Describe Faceplates. Previous: Unit 2: Speed and Feed Next: Unit 4: Turning Back to top. License. Manufacturing Processes 45 by LamNgeun Virasak is licensed under a Creative Commons Attribution International ...

Work Holding Devices in Lathe Machine and Their Types

· Four Jaw Chuck. It is also called Independent Jaw Chuck which consists of four jaws and each jaw can be moved separately by chuck 'key'. These jaws are reversible and have steps made on them, which can be used to mount workpieces or a job of different sizes.. This chuck is used to hold regular and irregular shaped jobs, heavy components and large diameter jobs.

Jaw Crusher Working Principle

Jaw crusher is widely used in industrial and mining enterprises, this is because the aircraft structure is relatively simple, and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment, gravel ancillary equipment, it also can be used alone. Get Price Inquiry. Structure of jaw crusher mainly include frame, eccentric ...

Physical Feature Thesaurus Entry: Chins and Jaws

· Things Jaws Do: drop open, clench ... HINT: When describing any part of the body, try to use cues that show the reader more than just a physical description. Make your descriptions do double duty. Example: Hank leaned back in his chair, hands laced lightly over his torso, considering me. I couldn't look at his eyes, too scared to see his decision there, so I stared at his chin—dimpled and ...

What Are The Differences Between Single And Double Toggle ...

· Double Jaw Crushers. Double toggle jaw crushers are usually used for crushing hard, abrasive rocks, glass and ferrous metals. Unlike single ones, double toggle jaw crushers are much heavier and have a lot of moving parts. Plus they don't include rotary motion. Instead they crush materials between two massive jaw plates. The crushing process happens, when the feed material .

Jaw Crusher|Describe An Open Circuit Crushing

jaw crusher > describe an open circuit crushing; Describe An Open Circuit Crushing. Describe An Open Circuit Crushing Grinding Mill China, Describe an open circuit crushing 49 6312 ratings the gulin product line consisting of more than 30 machines sets the standard for our industry we plan to help you meet your needs with our equipment with our distribution and product support system and ...

Gyratory Crusher : Principle, Construction, Working, and ...

· Difference Between Jaw Crusher and Gyratory Crusher : (i) It is a reciproing machine. (i) It is a gyratory machine. (ii) Intermittent in action,, discharge is discontinuous. (ii) Continuous in action,, discharge is continuous. (iii) It is a primary crusher. It takes a feed of larger size. (iii) It is a secondary crusher. It takes a feed of smaller size. (iv) The load on the motor ...

The Comparison of the Jaw Crusher's Threedimensional ...

· The Comparison of the Jaw Crusher's Threedimensional Design Methods Aug 11 2014. The threedimensional design of the jaw crusher refers to the following steps: process the assembly relationship and other information among the support structure, its shape, and various components into an easily controllable parametric variables and then modify the parameters to achieve the purpose of .

Character Descriptions: 7 Tips for Describing Faces in ...

A human face reveals a lot about a person. In creative writing, describing a character's face can uncover information about who they are and how they feel. Writers can zoom in on individual features, like the eyes or mouth, or describe a face in its entirety to paint a picture of a character. Learn how to develop a character through their most telling attribute—their face.

PQ University Lesson 7 Crushing Secondary Breaking ...

· Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws. One jaw is stationary while the other is moveable. The gap between the jaws becomes narrower farther down into the crusher. As the moveable jaw pushes against the stone in the chamber, the stone is fractured and reduced, moving down the chamber to the opening at the .

Describe Jaw Crushing Aggregate Processingjaw Crusher

Describe Jaw Crushing Aggregate Processing. Describe jaw crushing aggregate processing impact crusher zenith ltd experts in manufacturing and exporting jaw crusherimpact crus chat online crushed stone aggregatecrushed stone aggregate crushed stone aggregate mixed asphalt and crushed stone gravel or sand used for paving or roofing

Latest Posts

- repuestos para trituradora de mandibulas

- آثار تعدين الدولوميت على البيئة

- آلة تستخدم لطحن التوابل pdf

- نباتات اسمنت السعودية

- الكرة الذهبية طاحونة

- مصنّف غسل الحجر الجيري

- متوسط سعر طن لسحق ملموسة

- تكلفة آلة كسارة الحجر

- شركة تصنيع كسارات الجزائر

- صخرة الجزائر المهنية

- صيانة مطحنة الطحن الخام الرأسية

- ضاغط التعدين للبيع في بريتوريا

- تاريخ طحن وسحق الحجارة في السعودية

- مصنع كسارة المسار في مصر

- كسارة الحجر أوليمبوس

- Gravel Suppliers In Agartala

- Dot Web Crusher Seafight Key Reborn Empire Browser Gam

- Crushing Equipment To Mm Dihitung Pertambangan Batubara

- Impact Crusher Machine For Sale

- Desain Mesin Crusher Indonesia

- Crusher Pemecah Batu Bara Surabaya

- Crusher Suppliers Coal Gangue

- Grinder Machine For Jetbroach Cutter

- Boron Stone Grinding Plant Processing Machine Pakistan

- High Performance Coal Powder Processing Equipment Raymond Mill

- Robo Sand Ore Mining Machine

- Ways To Process Ores

- Chinese Unbalance Vibration Motor Yzo

- Thing For Fonri Furanice For Sand

- Potash Feldspar Grinding Machine