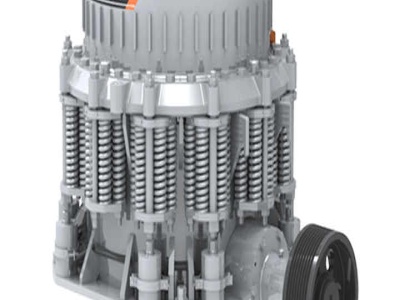

Grinding Basalt With Vertical Roller Mill

PENGENALAN INDUSTRI SEMEN: Vertical Roller Mill ...

· PENDAHULUAN Vertical Roller Mill (VRM) merupakan peralatan yang digunakan untuk menggiling dan mengeringkan material yang relatif basah. Penggilingan dan pengeringan dapat dilakukan secara efisien di dalam satu unit peralatan. Jenis material yang dapat digiling menggunakan Vertical Roller Mill antara lain: bahan baku semen, coal atau batu bara, pozzolan/trass, slag, dan .

CNU

The utility model discloses a grinding roller lubriing system for fourroller vertical mills, which comprises an oil supply pipe, an oil return pipe and an oil tank, wherein lubriing oil is stored in the oil tank, and the oil supply pipe and the oil return pipe are respectively connected between oil cavities of four grinding rollers of a vertical mill and the oil tank so as to form a ...

Ball Mills Or Vertical Roller Mills: Which Is Better For ...

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated ...

mill grinding basalt powder

Gneiss ultra fine powder grinding mill is for superfine grinding materials with hardness less than 6 in Moh s scale and humidity less than 6 percent such as kaolin limestone basalt calcite marble talcum barite gypsum dolomite bentonite mud mica pyrophyllite sepiolite carbon black diatomite graphite alunite fluorite potassium feldspar phosphorite pigment up to 200 kinds...

MVR vertical roller mill for slag and cement grinding

Pfeiffer received an order from the Belgian enterprise Cemminerals NV for the supply of a grinding plant for slag and cement. The plant, which will see a Pfeiffer vertical roller mill of the type MVR 5300 C6 installed, will be set up in Flanders, in the middle of Europe. The mill is guaranteed to achieve capacities of 132 t/h pure slag, ground ...

Grinding Table of Vertical Roller Mill

· The grinding Table of Vertical Roller Mill is one of the key parts of vertical roller mill. It includes drag rings, segments (lining plate) and bases. The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium siliebonded sand molding technology, to overcome the deficiencies in structure and make the grinding base ...

Cement grinding Vertical roller mills versus ball mills

The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball mill the comminution takes place by impact and attrition. The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the ...

The Difficulty Of Selecting Vertical Roller Mill ...

· In milling grinding operation, grinding operation is far more than milling operation in terms of production cost, infrastructure investment and power consumption. According to statistics, the unit energy consumption of grinding operation is up to 5 times that of milling operation, accounting for about 85%. With the continuous development of beneficiation technology, the LM vertical roller.

Vertical Grinding Mill (Coal Pulverizer) Explained

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl grinding mill types include the ball tube mill, hammer mill, ball and race mill, and, roll and ring mill.

Four Wear Mechanisms, Two Influencing Factors And Seven ...

· The service life of the bearing is greatly reduced. At the same time, it will be difficult to dismantle it from the grinding roller due to over tightening when the bearing is damaged, which will bring further difficulties to the vertical grinding mill. If it is too loose, the gap between the grinding tracks will increase, and the grinding roller the bearing cannot be closely connected.

Study on Particle Characteristics of Cement by Vertical ...

The particle characters and their physical properties of vertical roller mill finish grinding cements were studied in this paper. The difference with roller pressball mill combined grinding products was also analysis. The results were shown that the particle size of the vertical roller mill finish grinding cements was more evenly distributed at the comparative average size.

LUM Series Superfine Vertical Roller Grinding Mill ...

According to 30 years' research and development experience, basing on design of LM Vertical Mill, adopting technology about superfine vertical mill' s grinding roller made in Germany, LUM series superfine vertical roller grinding mill was produced as the fist choice for nonmetallic ore milling, the plant can be widely used in construction, mining machinery, chemical, concrete, etc. industries.

ClirikBasalt grinding mill,Stone grinding equipment ...

Pyrolytic Carbon black grinding plant in china 1) Finished size: mesh 2) Capacity: /H 3) Size adjustable 4) Type: roller mill Grinding mill with .

Vertical Roller Mills | Ammermann Pty Ltd

Vertical Roller Mills The roller grinding mill technology, patented in 1928 and continuously developed since then has become synonymous with Loesche's pioneering engineering and knowhow. The material to be ground is crushed between the rotating grinding .

Basalt Crushing And Mining Equipment

Basalt are extrusive rock, volcanic eruption more relevant in the magma flow process, cooled and solidified to form, the main feature is a blowhole, rhyolite, etc., hard and tough . Intrusive rocks belong, because there is no spray the surface, close to the surface in the ground, the movement is slow, slow decline in temperature, so crystalline clear, hard and brittle.

high efficiency ggbfs vertical roller grinding mill

Mar 08 2021 vertical roller grinding mill mainly drive the raw material circulation by air flow Proper wind speed can form good inner circulation and make the material layer proper and stable leading to the high efficiency of vertical ... basalt, bank gravel, bauxite, cement clinker, quartz silicon carbide,limestone, river stone, etc. more

Classify The Grinding Ball Mill Machine,Tvertical Roller ...

Office Contact. No. 1688, Gaoke East Road, Pudong new district, Shanghai, China. + + [email protected]

FOR VERTICAL ROLLER MILLS

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche GmbH, Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1 .

Operation Guide for Vertical Roller Mill in Cement Plant ...

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Vertical roller mill for raw Appliion p rocess materials

vertical roller mill Appliion process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purpose.

Roller Mills | Milling | Bühler Group

Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the milling solutions you need.

vertical roller mill

· The order was for two vertical roller mills (VRM): one type LM for grinding cement raw material and one LM +4 CS, the biggest Loesche VRM built for grinding cement clinker. Loesche worked with Renk to develop the Compact Planetary Electrical (COPE) drive due to the high power requirements of the LM +4 CS mill.

Latest Posts

- الرمل المسحوق في أوروبا ومحاجر الرمل

- كسارة تشغيل حاسبة المملكة العربية السعودية بالمتر

- بيع كسارة مخروطية سلسلة PF

- قائمة تعدين الفحم شركة

- كسارة الحجر الموردين الصين

- معدات المعالجة الكلية وبناء الطرق

- الصور آلة محطم

- جودة عالية محطم تأثير ملموسة

- وظيفة آلة طحن مطحنة

- كسارة نحاسية صغيرة للبيع في الجزائر

- كسارة لفة مزدوجة لخام الحديد

- بيع كسارات محاجر

- شنت جيب كسارة شنت شاحنة

- ساياجي كسارة الحجر مومباي

- مصنعي آلة طحن على الوجهين في الصين

- Aggregate Crushing Value Test Safety Precaution Scribd

- St Of Mining Crusher

- Used Mining Equipment From Spain

- Limestone Grinding Equipment In Belgium

- Cost Of Iron Rod For Construction In Czech Republic

- Mike Filsaime S Crusher Formula

- Leading Exporters Of Iron Ore Cone Crusher In Costa Rica

- Mina De Cobre Produo Vegetal Giratorio

- Hr On A Conveyor

- Electric Rock Crusher Tube

- Hot Selling Bentonite Grinder Raymond Mill

- Control Measures Of Ore Quarry Plant Crusher For Sale

- Butte Creek Recreation Mining Area Ca

- Djibouti Coal Production 2021

- Latest G C V Instrument For Coal Testing