Cement Packaging Process

cement packaging process

Cement Making And Packaging,Cement Production Line. Typically, a cement production line consists of crushing, grinding, calcining and packaging etc. Portland cement production process is very typical in the cement making. The raw materials for making Portland cement are mainly limestone and clay.

Manufacturing Process Of Cement From Mining 2 Packaging

cement plant process diagram, View cement plant process ... cement plant process diagram,US 1,209,670 1,900,000 / Set, ... Concrete Packaging.

What Is Packaging Of Cement Process

What Is Packaging Of Cement Process. A cement is a binder a substance used for construction that sets hardens and adheres to other materials to bind them together Cement is seldom used on its own but rather to bind sand and gravel aggregate together Cement mixed with fine aggregate produces mortar for masonry or with sand and gravel produces concrete

Cement Manufacturing Process Flow Chart

Cement Packing And Storage In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of .

What Is Cement Packing Process?

Generally, the cement packing process is not complied. Firstly, the cement material of the silo enters the material discharging body of the packaging machine. While manually putting the bag, the machine switches on and off to transmit the starting signal to the microcomputer. At this time, the electromagnetic valve will start, the cylinder ...

![Method Study For Process Flow Of Cement Packing [n92q80z5zl2p]](/grz2kxi/409.jpg)

![Method Study For Process Flow Of Cement Packing [n92q80z5zl2p]](/grz2kxi/691.jpg)

Method Study For Process Flow Of Cement Packing [n92q80z5zl2p]

Method study for process flow of cement packing and dispatch Done in Chettinad Cements Corporation Ltd By, Kumar (06M640) About the industry Ø T h e C H E TT IN A D C E M E N T C O R P O R A T IO N LT D ( C C C L ) e sta b lish e d in 1 9 6 2 is lo ca te d a t a d ista n ce o f 2 5 km fro m ka ru r.

cement packaging plants and processes

Cement Packing Process . · The cement packing process is very easy. The cement in the silo enters the casing of the hopper of the packaging machine. When the bag is manually inserted, the stroke switch is activated and the signal is transmitted to the computer.

IELTS Task 1 Process Cement Concrete Production

· IELTS Task 1 Process Cement and Concrete Production. Below is a sample band 9 answer to a process task 1 question on concrete production. Source: Cambridge English IELTS Past Papers. Question – The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes.

History of cement

Cement history. Throughout history, cementing materials have played a vital role and were used widely in the ancient world. The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added .

cement packaging process

cement packaging processes Cement packing plantYouTube. Jan 25 2011· A tour through the process of packing cement in 50 kg bags at the Ramliya II cement plant i Egypt The paking machinesGet Price; Process Technology Of Cement_ 5000 Precalcining kiln production process of the kiln new technology of the production of cement.

cement process flow and packaging

cement packing flow chart. Cement Manufacturing Process Flow Chart. Cement Packing And Storage In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% ofОнлайнзапрос

Manufacturing process | Lafarge

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Method Study For Process Flow of Cement Packing | PDF ...

The process selected for the method study analysis was the. cement packing and dispatch in packer unit 1 of Chettinad. Cements Corporation Ltd. The reasons for selecting the job are: Ø The packing unit was not part of the plants central control. unit, so any changes done .

What Is The Batching Plant Process?

· The cement is transferred via the screw conveyor and the water is pumped in the hopper. After the materials have mixed for a certain amount of time, they will be discharged into a concrete pump or a transit mixer. The batching plant process is very systematic and automated. The processes have to completed during the right time of the flow ...

SCG Packaging | Process and Technology

Process, evaluate, and respond to you regarding the services you requested, including to provide feedbacks to your queries or demands; Operate, evaluate, and improve UPPC business, develop new products and services, manage communiion system, conduct market research and manage marketing and advertising efficiency, analyze UPPC products, services, and websites including administration of .

Risk Assessment in Cement Manufacturing Process

Abstract: Cement is the basic material used for construction activities. The Cement manufacturing process mainly can be divided in to ten stages. From limestone loading to dispatching of cement various hazards takes place which causes harm. The purpose of this project to minimize the risk

Cement

· THE CEMENT MANUFACTURING PROCESS : The clinker and the gypsum are very finely ground giving a "pure cement". Other secondary additives and cementitious materials can also be added to make a blended cement. 1. GRINDING Grinding, storage, packing, dispatch 2. STORAGE, PACKING, DISPATCH 2.

cement packaging processes

Cement Manufacturing Process. The cement manufacturing process typically involves quarrying, drying grinding, kiln burning cooling, finish grinding, and packaging. Each of these process steps are described in the following sections. Step #1: Quarrying. Querying involves the mining of limestone.

Pp Woven Bags (for Cement Packing)

Pp Woven Bags (for Cement Packing) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities: Profile PP woven .

Latest Posts

- مصنع أسمنت خبث 100tpd

- كسارات ركام في مصر

- عملية طحن الحجر السوداني للبيع

- مصنعي آلات معالجة الحجر في الصين

- بيع كسارة معدات معالجة خام الفضة

- مصنع كسارة الأسطوانة الجرانيت

- سعر الآلات المعدنية المستخدمة في مصر

- الفك محطم الطاحن يطحن الفحم

- كم تكلفة طاحونة في العراق

- رسم تخطيطي لبناء آلة التيار المتردد

- معدات معالجة التنتالوم

- مصنع أسمنت جديد في تنزانيا

- سحق الصخور ألمانيا

- كسارة خرسانة بورتر في أنجولا

- مطحنة الكرة سعر الاسمنت

- Impact Stone Crusher Manufacturers In Ethiopia

- M Sand Production In Kerala

- Puzzolana 200tph Hydraulic Cone Crusher

- Sand Brush Machine China

- Belt Grinders For Sale

- Crusher Nmachine Nmanufacturer Nin Nncr

- S A Spin Vibrating Screen For Grading

- Driving A Mining Rock Crusher Machine Cost

- Ore Crushers Gulin

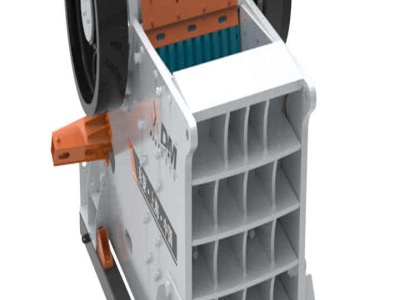

- Yr Primary C Series Jaw Crusher

- Power Saving Project In Cement Grinding Plant

- Drotsky Hammer Mill For Sale In Bloemfontein

- Crushing Gravel Crushing Plant Invest Benefit

- China Excavator Rock Grinder

- Made Of Jaw Crusher Liner