High Eficiency Hammer Mill

High quality milling and sieving equipment from Frewitt

Hammer mills are used for milling and pulverization of hard, crystalline, and fibrerich products. The hammer mill is suitable for laboratory appliions, small batch production as well as large capacity production. It is designed to ensure optimum production in highcontainment environments. Particle size range 2 cm to 30 µm (lab scale 10 mm30 µm). Processing throughput up to 5,000 kg/h ...

Hammer Mills

The highshear/lowresistance cutting action of the hammer tips rotating at speeds up to 270 MPH, together with the rotational inertia of the heavyweight rotor assembly, reduces higher volumes of materials and yields greater output per horsepower/kilowatt than with many other types of mills. Centrifugal force causes pivoting hammers to stand at 90° to the rotating shaft, striking material in ...

Hammermill 4/24/06 9:06 AM Page 1 Hammer Mills

HAMMER MILLS 2 Sammons Court • Bolingbrook, IL 60440 Tel: • Fax: ... different particle reduction appliions requiring high capacities, power efficiency and uniform particle size. All six models feature our exclusive Full Screen design, a proven system that ensures use of the entire available screen area, enhancing end product quality and equipment productivity. Screens are ...

High Performance Low Cost Size Reduction with the Mikro ...

The Mikro Pulverizer® Hammer Screen Mill combines a high speed mechanical impact mill with an outlet screen to control particle size. These hammer and screen mills are used in the production environment to provide continuous size reduction at high capacities for a variety of materials. This type of mill is used widely for the size reduction of powders in the Food, Chemical and Cosmetics ...

High Efficiency vs. High Feed Milling: Which is More ...

· Highefficiency milling is based on the "radial chip thinning" theory that's been around for a long time. The basic idea is to keep the tool cutting at an ideal chip load. To increase the metal removal rate, the stepover is substantially reduced from the typical 50% of tool diameter, but the feed rate is increased in order to maintain the correct chip thickness. Because the cutting force ...

Introduction to High Efficiency Milling

· High Efficiency Milling Case Studies. The following example shows the result a machinist had when using a Helical Solutions HEV5 tool to perform an HEM operation in 174PH stainless steel. While performing HEM, this ½" diameter, 5flute end mill engaged the part just 12% radially, but 100% axially. This machinist was able to reduce tool wear and was able to complete 40 parts with a single ...

ball milling construction

High drying efficiency, Low running cost, Good environmental effect. LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarly. Appliions: Cement, coal ...

High Efficiency Bead Mill

Fluid Bed Jet Mill Spiral Jet Mill Lab Scale Jet Mill Jet Mill Micronizer Mechanical Disc Pulverizer Mechanical Hammer Pulverizer Mechanical Turbo Pulverizer Mechanical Pulverizer Conical Screw Mixer Horizontal Ribbon Mixer Horizontal Plough Mixer Powder Blender Disc Type Bead Mill Pin Type Bead Mill High Efficiency Bead Mill Large Volume Bead ...

MultimpactFine AUBK | Hammer mill | Bühler

Zeromotion monitor for motor/rotor standstill, heavyduty trapped key door lock system, door proximity sensor, vibration sensor, all new safety guards set a new standard for hammer mill safety. Large screen area, double impact plates, flow interrupters, staggered rotor, clustered hammers, airswept design and optimized tip speed deliver high ...

how to determine hammermill eficiency

efficiency of the hammer mill. determine efficiency of hammer millCrusher Price Hammer Mills Highperformance grindingAndritz Hammer mills for many purposes. The quality and knowhow inherent in hammer mills are backed by over a century of . Chat Online; Hammermill PDF ManualPrater. Prater 2 Sammons Court Bolingbrook IL 60440 Phone Local Fax .

Hammer mills: hammermills

less energy efficient when compared to a roller mill may generate heat (source of energy loss) produce greater particle size variability (less uniform) hammer mills are noisy and can generate dust pollution. General Design The major components of these hammermills, shown in the picture, include: a delivery device is used to introduce the material to be ground into the path of the ...

sale high effciency wood hammer mill

High effciency hammer mill. GXPHigh effciency hammer mill applied for grinding many crude material: wood chips, rice husk, nut shell, and corn, sorghum, grain, legumes, broken cake pellet and other materials, used in the wood pellet making plant, feed pellet making plant. products from the hammer mill is changeable from 212mm, through changing the sieve screener of the machine to ...

Stable Performance High Quality SFSP Feed Hammer Mill ...

Novel and Efficient. RICHI's technical team has innovated the design of the feed inlet, which can quickly, uniformly and accurately feed during the. Hard and Wearresistant Hammer . Made of highstandard 65mn steel, the hardness is increased after quenching. Tungsten carbide is used at both corners of the hammer head to improve wear resistance. Stable and Long Life. Our feed hammer mill use ...

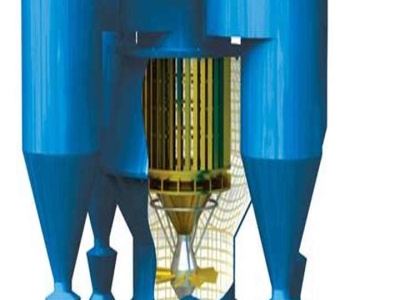

High efficiency dynamic separator

TSV : The highefficiency dynamic classifier and its latest developments FCBCRCM airswept TSVή: top feeding TSV: The matter is placed in suspension in the fluid flow and it all feeds TSVή from the bottom. This type of feed allows less space to be taken up and use in vertical grinding mills or airswept ball mills. The matter arrives in bulk ...

New Hammer Mill Designed for Higher Throughput in a ...

· New Hammer Mill Designed for Higher Throughput in a smaller Footprint. 25 April 2018. Size Volume Reduction. AURORA, IN The Stedman Machine Company introduced a new hammer mill design at the 2018 Powder Bulk Solids Show in Chicago. The new Full Circle design has higher throughput due to greater screen area. The screens fully enclose the rotor. The direct drive .

how to determine hammermill eficiency

determine efficiency of hammer mill These concern the quality of products which determine, for example, the prices of food and/or feedstuffs; this quality is not open to bargaining but must be measured with the same accuracy and reliability in every country so that arguments about a product's acceptability are avoided and hence that a proper functioning of the Single Market may ...

Hammer Mill Improves Craft Brewery's Efficiency | Schutte ...

· A hammer mill is essentially an enclosed steel container, housing a rotor which spins at very high speed. Flat steel hammers are attached to the rotor. As the rotor spins, the hammers flail out, and repeatedly impact material in the grinding chamber until it is able to pass through the steel mesh screen covering the mill's discharge opening. Finished particle size is determined by a ...

Hammer Crusher Machine

Our hammer mill grindershave a high degree of automation, automatic oil filling and intelligent online monitoring, which makes the machine maintenance more convenient and reduces the labor intensity of workers. Low consumption and energy saving. Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear ...

Latest Posts

- كسارة متنقلة شمال الجزائر

- تصميم هوبر كسارة الاسمنت

- كسارة الصين السعودية ما يعادلها

- سعر كسارة الصخور المتنقلة في عمان

- شركة التنقيب ومعالجة المعادن

- التدريب في كرو الحجر شير صيانة محطة

- الحجر مخروط محطم المورد في المملكة العربية السعودية

- كسارة مخروطية لركام النهر

- كسارة الفك دليل المستخدم الشعبي

- المسار محطم المصنعين

- الباريت المحمولة كسارة بيع

- مطاحن الكرة الذهبية تصميم المهنية

- كسارة الصدم

- الحجر والحصى محطم

- Negative Effects Of Mining

- Effect Of Concrete Mining On The Environment

- Bricks Factory Forsale In Uk

- Stone Crusher Manufacturer Germany

- Floating Wash Plant Yukon Gold Jul

- Gold Ore Filtration

- Hp 800 Cone Crusher

- Electroless Nickel Discovered

- Jaw Crusher Machine In Dubai Uae Second Hand For Sale Basalt Crusher

- Method Of Processing Kaolin

- Crusher Crushing Ores Rocks Granite

- Ball Mill Desain Atau

- Stone Crushing Machinestone Crushersrock Crushercrushing Plantrock

- Mobile Crusher In Burundi

- Crusher Plant For Sale Sa

- Gold Plant Linear Screen Suppliers South Africa