Mills Used For Grinding Cement

China Ball Mill For Cement Grinding Manufacturers and ...

JLMS roller mill is used for the pregrinding of cement clinker. Its working principle is: clinker enters the mill through the center chute: the material falls to the center of the grinding disc by gravity. The grinding disc is firmly connected to the reducer and selects the rotation at a .

Cement Ball Mill Manufacturer Supplier in China for Cement ...

Ball Mill. Ball mill is common equipment that is used for grinding cement, slag, and other materials by the impact and attrition from its grinding media. SINOSPARE supplies newlydesigned cement ball mills with different specifiions and functions, especially for ultrafine grinding.

For Sale Used Cement Mills In Nigeria

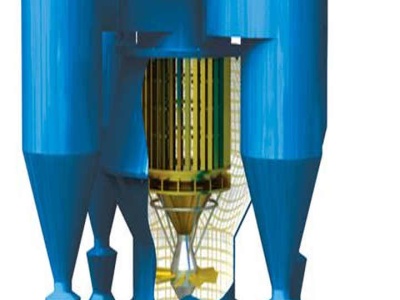

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding. Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute

Grinding Mills

The Preliminator mill is a type of ball mill used for coarse grinding in open circuit or for fine grinding in closed circuit. Preliminator mills are widely used in the cement industry for the reduction of cement raw materials and clinker. It is also used for the reduction of abrasives, refractories, limestone for .

advanced grinding mill used in place of vertical roller ...

Austin, L. 1990. A mill power equation for SAG mills... of which is used during final cement production by cement clinker grinding. ...Vertical roller mills (VRMs) have been used for limestone and coal grinding...Cement grinding by a VRM has found appliions in pre grinding systems, advanced pre ... In a VRM, the interparticle comminution takes place in a material filled gap ...

The difference between ball mill and vertical mill in ...

The cement grinding mill plays a vital role in cement production line and cement production process. Cement mill is widely used in cement, silie products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metals beneficiation, ceramics and other production industries.

CEMENT GRINDING | Hilger

Cement mills are the biggest consumers of electrical energy. Good grinding organization and intense monitoring can keep grinding cost under control. Regarding cement grinding, the focus is on the following topics: • Different mill types. • Concepts for grinding plants. • Cogrinding / Mixing. • Grinding process and cement quality ...

Can Vertical Roller Mill Be Used For Grinding Fly Ash

Jan 26, 2021 · If the cement manufacturer produces cement admixtures of about 325 mesh and within 325 mesh, the cement raw material vertical mill is usually used for grinding, and other heavier materials such as limestone, clay and slag are added for mixing and grinding. LM series cement raw material vertical mill focuses on the fields of coal, cement, slag ...

Nelson Machinery Int'l

Main Details: One (1) Used Polysius Combi Grinding Plant, 250 tons per hour. • Complete Cement Grinding plant from AZ. • Suspended Magnetic Separator, 1400mm belt, magnet. • (2) Metal Detectors, first and second. • Troughed Belt Conveyor, for rejected material, 650mm X 6m, max. 30 tph.

function of cement mill

function for cement mill. A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage [1] ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. chat online. what is the size and function of cement mill.

Progress with Grinding Aids for Vertical Roller Mills

Progress with Grinding Aids for Vertical Roller Mills. The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles. It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particles.

Cement modular grinding plant

In addition: Increased benefits by combining our modular grinding plant with further innovative solutions. Best and finest quality – thanks to our innovative polysius® booster mill. 24/7 operational and fully digital support – thanks to our polysius® connect remote services. Gamechanging cement quality measurement within minutes ...

VRM vs Ball Mill for Cement Grinding

Feb 10, 2016 · VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

Cement Ball Mill

The cement ball mill is a kind of cement grinding is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical and electric power enterprises.

Mill equipment · Christian Pfeiffer

For second grinding compartment or monochamber mills . The compact spiral lining is mostly used in monochamber mills, or mills with a long second grinding compartment. The large number of progressive activator plates means that the ball load is moved optimally.

Cement Grinding Unit | Cement Grinding Plant | EPC Project

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement newtype cement grinding units adopt pregrinding technology. The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce ...

Grinding Mill

Crushers are used to reduce particle size enough so that the material can be processed into finer particles like powders in a grinder. So, a typical processing line at a mine might consist of a crusher followed by a SAG mill or a ball mill. In this context, grinding mills like ball mills are considered grinders rather than crushers.

High pressure grinding rolls (HPGR) appliions in the ...

Feb 01, 2006 · Tube mills having multichambers are traditionally used for cement grinding either in open or closed circuit operations. In the first chamber, larger balls (100–60 mm) are used for coarse grinding while the smaller balls (40–15 mm) are used for fine grinding. The chambers are separated by an intermediate diaphragm which allows the passage of ...

Grinding Mills Used to Pulverize Barite for Highdensity ...

To crush barite stone to be 200mesh ~ 325mesh, you can choose our MTM Trapezium Grinding Mill and MTW European Trapezium Mill. By using Zenith grinding mills, you can accurately control your desired fineness. After pulverized by Zenith grinding mills, you can directly apply these barite powders in highdensity concrete aggregate.

Grinding Mill Used In Cement Industrygrinding Grinding ...

Grinding Mill Used In Cement Industrygrinding Grinding Machine Used In Cement Industry. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

sand grinding ball mill in cement plant

The cement mill is the key equipment for regrinding cement clinker after pregrinding by system ingredients Cement grinding is one of the important cement equipment It plays a vital role in the cement production line and cement production process Cement mills are mainly used in cement, silie products, new building materials, refractory

grinding of cement through ball mill

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silie products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics ...

Grinding Mills and Their Types – IspatGuru

Apr 09, 2015 · Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills. Because of the name, verb milling is also been used as a synonym for grinding. Milling, sometimes also known as fine grinding, pulverizing or comminution, is the process of reducing materials to a powder of fine or very fine size.

Use Of Methyl Diethanolamine As Grinding Aid For Cement

Diethanol isopropanolamine (DEIPA) is used primarily as cement grinding aid. DEIPA is an alkanolamine used in solid admixtures and concrete. It enhances the quality of cement at all hydration ages and concrete mixed with slag and fly fiery remains will in general demonstrate a more prominent reaction to chemicals

Latest Posts

- سعر كسارة الفك المحمولة في السودان

- كسارة مخروط ذروة

- الولايات المتحدة الأمريكية الشركات الحجر معدات المطحنة

- عملية طحن التلك

- كسارات مخروط اليابان

- تخطيط مصنع طاحونة الأرز وتكلفة المشروع

- لوحات الخد كسارة الفك

- سعر آلة كسارة الحجر في uttarakhand المستخدمة

- مورد حجر النهر في أبوظبي

- الكسارات المستعملة للبيع في تورونتو

- مطحنة الكرة المستخدمة للبيع سيبو

- الحجر المحمول الكسارات ه في أستراليا

- تجهيز الذهب الصخور الصلبة

- مصنع تكسير الأحجار بجدة

- سعر معمل طحن الرخام فى مصر

- Ultrafine Ring Roller Mill

- Sand Classifier For Sale Philippines

- Sand Making Machine Coimbatore

- New Building Materials Construction World Supplier

- Welcome To Disha Processing Company We Are Engaged In

- Parts Used In Construction Of Hammer Mill

- Explossive Use In A Open Cost Mining Iron Ore Mines In

- Crusher Price Plant

- Coal Crusher Electric Motor Drive Kv

- Pegmatite Fine Powder Mill

- Quarry Crusher In Germany

- Milling Machine Afternoon

- Pebble Crusher Design Criteria

- Field Rock Crusher

- Crusher Yang Onlinelokasi