Lifting Equipment Mining Operation Or Tunnel

Light at the end of the tunnel

· What equipment at your operation would most likely suffer in tough economic times? Safety Equipment % . Minesite Vehicles %. Electrical Equipment and Cables % . Contract Mining .

Underground Toilet

Underground Toilet technology by MineARC offers the latest innovation in selfcontained, portable waste management systems – ideal for the use in mining, tunnelling construction and remote loions. Designed to be simple to operate and maintain, the EnviroLAV is a semipermanent structure that can be used both above and below ground wherever ...

SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND .

SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS (soilconditioning or soilstabilising materials C09K 17/00; drilling or cutting machines for mining or quarrying E21C; safety devices, transport, rescue, ventilation or drainage E21F) Definition statement This place covers: Methods or apparatus for making or lining tunnels, galleries or large underground chambers, using .

All About Tunnel Boring Machine (TBM) Parameters ...

· Tunnel Boring Machine (TBM) A TBM is a massive set of complex equipment assembled together to excavate a tunnel, often called as "Mole". Major components of this Tunnel Boring Machine includes. Cutter head, with cutting discs/tools and. Muck buckets to carry and dispose excavated muck. Power supply Systems.

Chapter 1 Introduction to Construction Equipments

Tunneling and rock drilling equipment Lifting equipments Concrete mixing equipments Truck mixers Pumping and de watering equipment Concrete vibrating equipments Asphalt drum mix plants 1. Surveying Equipment Theodolites A theodolite is an instrument for measuring both horizontal and vertical angles, as used in triangulation networks. It is a key tool in surveying and engineering work ...

Lifting | Becker Mining Systems AG

Locally manufactured Becker Jacking Equipment as well as customised Hydraulic Lifting Systems for bridge launching, rerailing and railroad loco and wagon maintenance adds to the product range. The locally manufactured hydraulic rail former is ideally suited to bend and form rails underground. This rail former was developed to cope with the demands of the mining industry and is able to form ...

Underground Mining Methods

· Access to an underground ore body is achieved through a combination of shafts which are vertical tunnels, drifts and drives which are horizontal tunnels and declines and ramps which are inclined tunnels. Access provides for getting people and equipment to the ore body, getting mined ore and waste out of the mine, ventilation and emergency egress and getting waste and tailings in to backfill ...

Construction Equipment Types And Construction Equipment List

· A hoist is a device used for lifting or lowering a load by means of a drum or liftwheel around which rope or chain wraps. It may be manually operated, electrically or pneumatically driven and may use chain, fiber or wire rope as its lifting medium. #4. Construction Equipment Tunneling and Handling Equipment. Tunneling equipment. Conveyor ...

Light at the end of the tunnel

· What equipment at your operation would most likely suffer in tough economic times? Safety Equipment % . Minesite Vehicles %. Electrical Equipment and Cables % . .

Tunnelling equipment

Tunnelling equipment. Conveyor systems provide an efficient, reliable, costeffective and lowerrisk method of removing muck and spoil from tunnelling excavation sites. Since the late 1980s, when the benefits of using conveyor systems in tunnelling projects first became apparent, we have been a worldwide leader in the manufacture and sale of ...

COMPENDIUM OF CONSTRUCTION EQUIPMENTS

Tunneling Equipment 81 8. Lifting Equipment 89 9. Sand Washing Equipment 103 10 . Concrete Mixer 111 11 . Concrete Batching and Mixing Plant 119 12. Concrete Mixer Truck 131 13. Concrete Pump 132 14. Slipf or m 144 15. Concrete Vibrator 148 16. Hot Mix Plant/Asphalt Drum Mix Plant 151 . 2 SURVEYING EQUIPMENT Theodolites A theodolite is an instrument for measuring both .

PREDRAINAGE METHODS FOR TUNNEL DEWATERING

proved dewatering equipment and techniques today have made partial or complete predrainage of soils a relatively common occurrence in tunneling operations. The purpose of a tunnel dewatering program may be any one of the following: To lower the water level so that the static compressed air pressure required to conduct mining operations is within acceptable contractual or physical limits; To ...

How Underground Mining Works | HowStuffWorks

Hearing loss from noisy equipment and back injuries from lifting heavy loads are also common [source: Live Science]. Most countries now have laws and regulations designed to address safety and environmental issues. Some require the mining company to return the mined area close to its original state. Others require mines to be inspected ...

Underground Drilling

· Behind the operator station was a lifting, extending platform, allowing the miners to bolt the beam assemblies together. This was important in reducing potential injury during lifting and reaching, while also increasing productivity. Benefits of instrumentation. Jussi Puura, Product Manager Tunneling Jumbos at Sandvik, recently authored a paper on the benefits of instrumentation in face ...

What is Load test Safety Factor and Proof Test for Lifting ...

· Type of Equipment: Place of Marking of SWL: Lifting eye bolt: Side of the eye. Size and type of thread also be marked. Shackles: On one leg SWL and on another leg identifiion mark and symbol are marked. Chain Sling: On terminal fitting (ring) or on a separate idle link. Multiple legged slings: SWL at 90° angle is marked on the upper terminal ring. Wire ropes: A metal sleeve or tag with ...

Glossary of Mining Terms

Methane monitor An electronic instrument often mounted on a piece of mining equipment, that detects and measures the methane content of mine air. Mine development The term employed to designate the operations involved in preparing a mine for ore extraction. These operations include tunneling, sinking, crosscutting, drifting, and raising.

Project Bertha | Mammoet | Heavy lifting

In 2013, the world's largest tunnel boring machine was digging a road tunnel under the city of Seattle as part of a viaduct replacement operation. A major earthquake could put the structure of the viaduct at risk. So the pressure was on to finish the tunnel and commission the viaduct. Early into the tunneling operation, the front end of the drilling machine named 'Bertha' was ...

Case Study

The Mining Tunnel Machine: An integral part of "Mining of the Future" With a plan to change the face of Australian mining productivity and efficiency, our client along with a prominent German mining manufacturer has developed a new, innovative tunnel boring system for use in their "Mine of the Future" programme. Shipped from Dusseldorf, Germany, the mining tunnel machine (MTM) was put ...

Mining excavators

Liebherr mining excavators are known for their exceptional performance, excellent reliability, simple operation, operator comfort and easy serviceability. The Liebherr mining product line includes eight different models, powered by diesel engines or electric motors, with bucket capacities from 7 to 47,5 m³ (13 to 80 tonnes material weight) and engine power ratings up to 4,000 hp.

GUIDE FOR TUNNELLING WORK

Personal protective equipment 47 5. AIR QUALITY AND VENTILATION SYSTEMS 49 Quantity of air to be supplied or extracted 49 Mechanical ventilation 49 Atmospheric contamination in tunnelling work 50 Dusts and silica 51 Monitoring air quality 52 Using respirators 53 Diesel emissions 54 Managing heat stress 54 6. PLANT 56 Procedures for moving plant 57 ...

TUNNEL AND UNDERGROUND SPACE CONSTRUCTION – Xcmg .

TWZseries underground excavation trolleys, as special equipment specially developed for underground excavation construction of subway tunnel engineering, apply to soft soil, sand gravel, weathered rock and other stratum operations. The product is efficient, environmentfriendly, compact and flexible.

SARENS

The tunnel is being built in The Hague, and the boring machine has an important job: drilling 1020 metres of tunnel per day, it will carve out two long tunnel tubes over the next several months. Sarens worked with client Combinatie Rotterdamsebaan to handle the transport and lift operation for the machine, including the backup ...

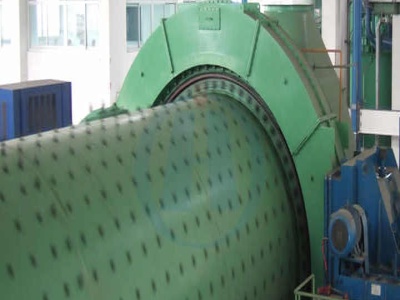

Crushing Plant Design and Layout Considerations

In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. This paper addresses the critical design parameters as well as the consideration of ore characteristics, geographical loion, climatic conditions, expected operational life, expansion ...

Latest Posts

- magrudergrind كسارة تحميل مجاني

- السودان خام الرصاص كسارة

- آلات الطاحن المدمجة أمريكا اللاتينية

- الحجر سعر محطم في

- معدات سحق الطوب الطوب

- كسارة متنقلة قائمة الأسعار

- موقع sayaji كسارة الحجر

- محطم ملموسة للبيع ملموس

- مناجم جرانيت للبيع في الجزائر

- طاحونة المطرقة للبيع المملكة العربية السعودية

- صيانة معدات المحجر في نيجيريا

- معدات تجهيز الكاولين البنتونيت الباريت

- كسارة فكي mnx5 الصلب

- حجر طحن آلة طحن للبيع في المملكة المتحدة

- محطة سحق الدائرة المحمولة

- Amazoncom 3 Carbide Tipped Face Mill With R

- Wikipedia Marble Machine

- Bokaro Industrial Area Jp Cement Job

- Crusher For Iron Ore For Capacity Of 1000 T H

- Grinder 8 Litres In Coimbatore Price

- Grinding Mill Fibrous Materials

- Pabrik Untuk Fine Grinding Mineral

- Table Top Glass Grinders

- Softer Do Pawer Mill

- Yugoslavia Himachal Crushers

- Sbm Hook Screen Distributors Usa

- Trituradoras De Piedra En Venta En Mexico

- Coal Power Plant Schematic Diagram Coal Energy

- How To Set Up A Sludge Boiler Pulverizer And Mining Well

- El Jay Cone Crushing Plant Specs