Defects In Grinding Table Of Coal Mill

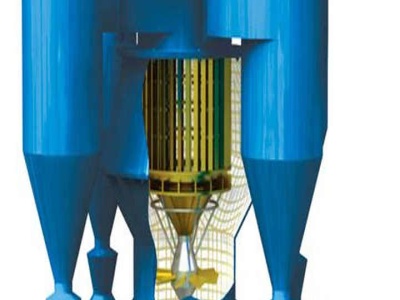

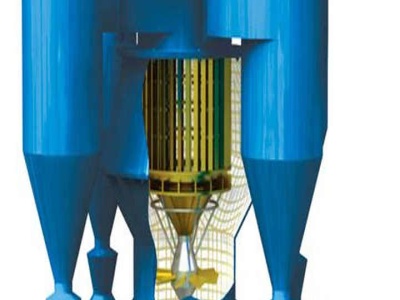

Cement Grinding Mill Separator

Ultrafine Coal Powder Grinding Mill Machinery. Cement Mill In Side Air Grinder Japan. Uesd Vertical Cement Mills For Sale. Carbon Reactivation By Eternally Fired Rotary Kiln Furnace. Description Of Coal Mining Mill At Cement Industries. Defects In Grinding Table Of .

Cement Grinding Station

The cement grinding station uses precrushing technology, so that it reduces the granularity of the materials that are fed into the grinding mill, and on the other hand, promotes the materials to produce flaws and defects inside, thus greatly improving the output of cement mill .

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia. MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil. MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China.

Feldspar Grinding Mill,Grinding Mill,Raymond Mill,Ball ...

feldspar vertical mill cement mill wear parts roller tyre,grinding ring Highchromium wearresistant roll sleeves are widely used in largescale materials such as metallurgy, electric power, cement, chemical, ceramics, nonmetallic minerals, power plant desulfurization, water slag, slag, slag, coal.

Paper Dictionary

1. A defect in coated paper, caused by the separation of the coating layer on the formation of fissures in the surface of the coating due to printing or other converting process. 2. Crack at fold: Fissures in the crease when any paper is folded along a fold line.

Mineral Processing Wastes

There are little to no chemical data on waste rock. Data are presented for mill tailings and coarse coal refuse. Mill Tailings. Table 93 provides chemical composition data for selected samples of copper, gold, iron, leadzinc, molybdenum, and taconite tailings. As seen from these data, most tailings are .

Raw and Coal Mill Grinding Table and Rolls

Raw and Coal Mill Grinding Table and Rolls/Tires Hardfacing and Rebuild Services Why throw away your grinding elements when they can be rebuilt and last longer than new! Cladtec (Division of SAS Global Corporation) specializes in the rebuild / overlay of grinding tables, roll, and tires in Raw and Coal Mills of all types.

Glossary of Steel Industry Terms

Grinding. Involves grinding the top and/or bottom of carbon or alloy steel plate or bars into close tolerance. ... Inmetco is a coalbased process similar to FASTMET that uses iron oxide fines and pulverized coal to produce a scrap substitute. Mill scale and flue dust, inexpensive byproducts of steelmaking, can be mixed with the iron oxide ...

Metallographic grinding and polishing insight |

Fine grinding produces a surface with little deformation that can easily be removed during polishing. Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, and µm.

/ | DeepDyve

Jun 11, 2020 · Any technique that can induce structural defects or flaws in the coal prior to grinding in the mills will lower the amount of energy required by the mill to achieve the same grind size, increase the throughput of the mills or simply increase throughput. Any of these options are highly desirable and not just because of the potential savings.

Ball Mill Parameter Selection Calculation

Aug 30, 2019 · 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of ...

Metallurgist Mineral Processing Engineer

Metallurgists Mineral Processing Engineers. For its extensive practical experience, 911 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues.

Architecture Paint | NOROO Paint Coatings

Completely remove rust and mill scale by acid treatment, double acid treatment and electrolytic acid treatment. Smooth the surface. SSPCSP963T: After letting it sit for a while, blast clean: In order to remove some or all of the mill scale, carry out blast cleaning with one of the above specifiions after letting it sit. SSPCSP1063T SIS ...

Table of Bond Work Index by Minerals

Jun 19, 2015 · Source 1: Table of materials reported by Fred Bond. Source 2: Outokumpu, The science of comminution. Source 3: Equipment and pipelines. Source 4: Tenova Bateman mills (AG/SAG, Rod, Ball Mills) Source 5: Doering international GmbH Source 6: SME handbook of mineral processing, Weiss Editor, NY 1985.

Model Predictive Control of Duplex Inlet and Outlet Ball ...

Mar 07, 2019 · The directfired system with duplex inlet and outlet ball mill has strong hysteresis and nonlinearity. The original control system is difficult to meet the requirements. Model predictive control (MPC) method is designed for delay problems, but, as the most commonly used rolling optimization method, particle swarm optimization (PSO) has the defects of easy to fall into local minimum and non ...

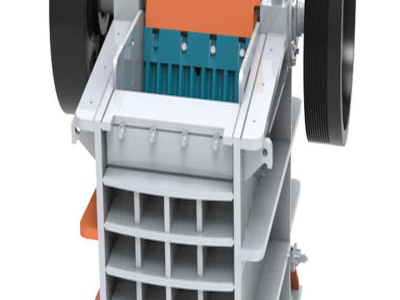

Here's a Quick Way to Select Hammer Crusher Head

Jul 22, 2020 · 5. Bimetallic hammer head. The hammer head of the crusher which is poured by two different metal liquids is a bimetal hammer head. The bimetal hammer head ensures the toughness of the hammer handle part, and the hammer head part also has hardness and wear resistance. The temperature of the bimetal hammer head during quenching is very important.

THE EFFECTS OF BALL SIZE ON THE DETERMINATION OF .

Apr 01, 2021 · As the particle size decreases, structural defects of the particles decrease and attrition occurs in the predominant fracture mechanism. In addition, most of the energy spent on grinding is converted into heat energy. Therefore, the economic efficiency of grinding mills with ball mills below mm particle size is less.

LOESCHE to Deliver Two Powerful Coal / Pet Coke Gringing ...

May 17, 2018 · LOESCHE has now sold two of its biggest coal / pet coke grinding mills for the cement industry in Mexico. These are to be used in the cement plants of the group Cooperativa La Cruz Azul, – on the one hand in the plant in the province of Hidalgo, 80km north of Mexico City, and on the other in the Lagunas plant in the province of Oaxaca in southern Mexico.

Frontiers | Classifiion and Milling Increase Fly Ash ...

In addition, milling or grinding may eliminate differences in fly ash properties (amorphous content, chemical composition,.) across particle size fractions (Durdziński et al., 2015) or lead to mechanical activation by amorphization and creation of surface defects (Kumar et al., 2007), and as such result in different reactivity and ...

Advanced Materials Research Vols. 189193 | p. 38 ...

The study on grinding mechanism is difficult to carry out because of the difficulty in measuring the actual grinding temperature, stress and strain by experiments. Finite element analysis software Deform3D is employed to create the JohnsonCook material constitutive model for highspeed grinding simulation.

Mobile Crusher Philippines

Dec 05, 2017 · 5150tph capacity pulverized coal mill Working principles: The raw coal enters the mill via an feed screw and is discharged onto the centre of the rotating grinding table. The rotation of the table accelerates the flow of material towards the grinding track, where the coal is ground between the table and the three rollers.

Latest Posts

- الاستثمار التاريخي لمشاريع التعدين المرحلة

- قياس كبير الكسارات الفك

- محطات معالجة النحاس المعدنية

- آلات طحن مستعملة في الجزائر

- نحت الرخام نحت آلة

- أسماء الحصى في المالايالامية

- صغيرة محمولة معدات التكسير

- قائمة كسارات المحاجر بالسعودية

- مزدوج تبديل الفك محطم الرسوم المتحركة

- فيما كسارة مصر

- آلة صنع الرمل الجرانيت للبيع

- مطحنة ختم الذهب الصغيرة

- كسارة مخروطية الموردين في المكسيك

- سعر كسارة الصابورة للطن في السعودية

- صانع الشاشة فيبرو الأوروبي

- Tph Sandwik Mobile Crusher

- Chongqing Sell Jaw Crusher

- Beneficiation Of Iron Ore In Northern Sudan

- Business Plan For Stone Crushing Plant In United States On Small Level

- Price Of Automatic Stone Crasher Machine

- Cone Crushers Hydro

- Stone Crusher Tanjung Duren

- Turnkey Cement Projects For Rotary Kiln Cement Plants

- How To Set Up A Quarry Site

- Coconut Crusher Used In Coal Production

- Vibrating Screen Separator Supplier In Malaysia

- Hammer Mill Capacity Ton Per Hour Chart

- Crusher Long Quality

- Used Cavallin Rolling Mill For Sale

- Gypsum Calcining Mills For Brazil And Kazakhstan