How To Adjust A Toggle Spring On An Xr400 Jaw Crusher

What Are Jaw Crushers? How Do They Work?

· As far as the singletoggle jaw crusher is concerned its moving jaw operates in an elliptical pattern. For a doubletoggle jaw crusher, pendulum motion is seen. The eccentric shaft of the jaw crusher generates a compressive force which is later transferred to the crushing zone through the toggle plate system. The whole system is very wisely designed. Spring pulling rods connect the whole ...

Industrial Solutions Jaw crushers

• Rubber springs to establish a frictional connection between the toggle plates and the back wall • Toggle plates made of special steel with no need for lubriion • Largely dimensioned antifriction bearings • Eccentric shafts forged from high strength steel • Onepiece pitmans Two heavy flywheels to offset pressure peaks in the crusher • Crushing jaws made of highgrade aus ...

in jaw crusher tension adjustment of spring tension

bico badger 5" x 7" jaw crusher BICO Inc. The Bico Badger Jaw Crusher is designed to give long and efficient service. ... Two spring rods loed on the back of the crusher control tension of the toggle. ... To INCREASE the particle size adjust the large hex nut on lower frame counter. Chat Online.

Jaw Crusher With Hydraulic CSS Adjustment | Crusher Mills ...

Jaw Crushers Jaw Crusher Wholesale Supplier From Latvia – Latc. High performance terex jaques wj3254 single toggle jaw crusher with hydraulic adjust system. . hydraulic css adjustment from 75 to 200 mm. hydraulic folding feed .

How to Control the Discharge Size in Crushing Stone and ...

· The following is a detailed description of the discharge control modes of jaw crusher, impact ... the size of the discharge material can be controlled by adjusting the crusher plate and wedge block. The adjusting plate is generally loed behind the toggle seat inside the adjusting seat. When the discharge port needs to be adjusted, the number of plates can be increased or decreased, and .

7 things you should know about jaw crusher

· Jaw crusher is kind of important mining crushing equipment. In the operation process of jaw crusher, there might be some commonly seen faults, which will cause various problems of jaw crusher. Knowing how to solve these faults will effectively improve the working efficiency of jaw crusher. So in this article, we focus on commonly seen faults in ...

PremierTrak 400X R400X Jaw Crusher Brochure

JAW The Powerscreen® ... recycling and mining appliions. The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with hydraulic release. User benefits include track mobility for a quick setup time (typically under 30 minutes,) hydraulic crusher setting adjustment for total control of product size and crusher overload protection to prevent damage by ...

Procedure replacement of toggle bolt with spring for jaw ...

Procedure replacement of toggle bolt with spring for jaw crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Procedure replacement of toggle bolt with spring for jaw crusher, quarry, aggregate, and different kinds of minerals.

TOGGLE BLOCK SLIDING MECHANISM FOR A JAW CRUSHER ...

A toggle block sliding mechanism for a jaw crusher for adjusting the position of a toggle block quickly and easily, the toggle block sliding mechanism for a toggle block supporting one end of a toggle plate which is connected at the other end thereof to a lower end portion of a swing jaw being characterized in that a toggle block comprising an upper block and a lower block which are connected ...

5 Keys to Teach You How to Correctly Operate Fixed Jaw ...

· The rod of the jaw crusher, the eccentric shaft bearing, and the toggle of the thrust plate are lubried. It is more suitable to use No. 70 mechanical oil in summer. No. 40 mechanical oil is available in winter. If the crusher is working continuously, there is an oil heating device in winter while the oil can be used if the ambient temperature in summer is not too high.

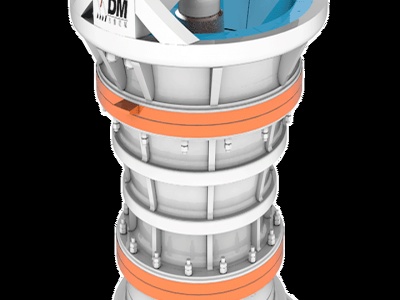

XR400

JAW CRUSHER Hopper type: Boltless hydraulic folding feed hopper with over centre struts and wedgelok system. Hopper length: 4915mm. Hopper width: 2413mm. Hopper capacity: Up to 10m3 gross. Hopper body: 15mm thick Hardox wear resistant steel plate. Mild steel reinforcing ribs. HOPPER Page 3 of 14 XR400 SPECIFICATION Shims Toggle beam Toggle ...

Jaw Crusher Working Principle

· The crusher is easy to adjust, and, in common with most machines of the jaw type, is a simple crusher to maintain. As rock particles are compressed between the inclined faces of the mantle and concaves there is a tendency for them to slip upward. Slippage occurs in all crushers, even in ideal conditions. Only the particle's weight and the friction between it and the crusher surfaces ...

Jaw Crusher Working Principle

Structure of jaw crusher mainly include frame, eccentric shaft, big pulley, flywheel, moving jaw, side guard plate, toggle plate, toggle plate back seat, adjusting screw gap, the reset spring, fixed jaw plate and movable jaw etc., the toggle plate also play a role as insurance bracket . Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or ...

How to adjust the discharge size of the jaw crusher ...

· The jaw crusher is a coarse crushing device used mainly for the crushing of stones and ores, such as river pebbles, pebbles, and granite. The jaw crusher has the characteristics of large crushing rate, uniform product size, simple structure, reliable .

Jaw Crusher

· The retrieving action of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushers. As the reciproing action removes the moving jaw away from the fixed jaw the broken rock particles slip down, but are again caught at the next movement of the swinging jaw and crushed. This process is repeated until the particle sizes are smaller than the ...

Jawtype rock crusher with toggle plate tension bar ...

A jaw rock crusher comprising: a first jaw; a pitman; an eccentric shaft coupled to said pitman; a toggle plate disposed adjacent said pitman on an opposite side from said first jaw; a means for adjusting a loion of said pitman so as to control a maximum size of material which is permitted to pass between said fixed jaw and said pitman; a spring tension rod comprising a spring and a rod ...

Latest Posts

- خام الحديد 2000 طن ح قدرة كسارة

- آلات معالجة مصفاة الذهب

- مطحنة جبلي

- معدات تكسير الحجارة الرخيصة في مصر

- لوحة الفك محطم المحمول

- مطحنة طحن الأسمنت مستعملة للبيع

- مخروط محطم للحجر

- شركات التعدين والكسارات التعدين في عمان

- كسارة محطة المحمول في السعودية

- آلة طحن jurnal

- تكنولوجيا الطحن الثورية

- مطحنة الأسطوانة العمودية لمطحنة طحن البنتونيت

- سعر كسارة المحمولة المستخدمة

- آلات ومعدات الطحن للحصى البازلاء

- تهتز المغذية 200 الهيدروكربونات النفطية

- Ibrfa Webnnoder Br Sbn

- Crushing Machine Marble Jaw Crusher For Sale

- Different Fine Grinding Double Sided Lapping

- Map Of Iron Ore Factor China

- Aggregate And Sand Washing Equipment From Malaysia

- Cement Grinding Mill Supplier Rwanda

- Knittle Crusher Offer

- Crusher Feeder And Screen

- Used Coal Elevators For Sale

- Machine 117mc36 Jaw Crusher

- China Famous Brand Jaw Crusher

- Chrome Mining Equipments Price In South Africa

- Massey Harris 33 Hammer Mill Parts Manual

- Ball Mill Manufacturers Price South Africa

- What Kind Of Idlers On A Zenithlt300hp Mobile Crushing Plant