Crushing Slag And Matter

crushing slag and matter

Crushing Slag With Metal Disseminated metal concentration concentrating metal containing slag particles before it undergoes separation, through crushing and jigging, protects crushers at little expense. disseminated metal removal reducing metal content through effective sensorbased sorting enables producers to sell safe slag products as aggregates and grinding media.

Crushing Slag And Matter, Jaw Crusher

Crushing Lead Slag Indoor Youtube, May 02 2016 crushing slag indoor to avoid that contaminated particles get into our environment additionally the onboard dust suppression system is used to reduce the amount of dust in the air a regular Crushing Slag And Matter

Extractive Metallurgy of Copper

Matte and Slag 74 Slag 74 Calcium Ferrite and Olivine Slags 79 Matte 81 Reactions During Matte Smelting 82 The Smelting Process: General Considerations 83 Smelting Products: Matte, Slag and Offgas 84 Matte 84 Slag 84 Offgas 86 Summary 86 References 86 Suggested Reading 88 6 ...

(PDF) Assessment of physical techniques to regenerate ...

Several techniques were performed to expose Keywords: fresh surface sites on the slag, including: (1) drying; (2) agitation; and (3) crushing of the Active filters slag granules. Crushing resulted in the best regeneration of P removal efficiency by the slag, Melter slag however, after just 2 months the renewed P removal efficiency of the ...

Fives | Selective crushing grinding with FCB Rhodax® 4D ...

The FCB Rhodax® 4D is ideal for numerous dry process appliions, including fused alumina, fired clay, silicon, ferroalloys, mattes, slags and concrete recycling.. This advanced vibrating cone crusher delivers constant product quality and particle size distribution thanks to interparticle features: High flexibility, liberation ratio and reduction ratio

Effect of TiO2 on the Crushing Strength and Smelting ...

· It was observed that most notdripped slag–iron was in the upper layer of the reduction matter in the crucible in which the slag accounts more than the melted iron. This slagiron did not drip smoothly in the experiments due to the fact that foamed slag with the generation of TiC and TiN appeared in the meltingdripping process. In practical production, it is of vital importance that the ...

Compositional modelling and crushing behaviour of MSWI ...

· Slag and Mslag are found to be present in the finer fractions of which the content increases after crushing in correlation with their determined crushing values (Fig. 5 and Fig. 6a and b). The near absence of refractory in the fractions <125 µm correlates to the higher crushing resistance of this class. Originally, both the glass and the refractory classes have a relatively narrow ...

Sand For Concrete From Steel Mills Induction Furnace Waste ...

The emission from induction furnace include suspended particulate matter, oxides of sulphur, oxides of nitrogen, and CO2 emissions will be more during charging of material to furnace. It could be recommended that slag could be effectively utilized as aggregates in all concrete appliion. The consumption of slag which is waste generated by steel industry, in concrete not only helps in ...

Cold Crushing Strength (CCS) of Refractory Bricks and ...

· Cold crushing strength (CCS) of a refractory brick represents its strength. That is it tells us how much load that refractory can bear in cold conditions. The concept of testing CCS of a refractory material has perhaps, come from metallurgy. This is because for any refractory brick it is rather; rare that it would fail simply due to load on it in cold condition and therefore, the determination ...

Mining Equipment, Breaking, Drilling Crushing Products ...

Our constantly evolving offering for mining and rock excavation covers rock drilling, rock cutting, crushing and screening, loading and hauling, tunneling, quarrying and breaking and demolition. No matter the terrain, material or ground hardness, we'll ensure you're matched with the right solutions to maximize your productivity and profitability.

Recovery of Valuable Metals from Nickel Smelting Slag ...

Nickel smelting slag contains valuable metals including nickel and copper. Failure to recycle these metals wastes resources, and disposal of nickel slag in stockpiles results in environmental pollution. Nickel slag recycling is important, and metals can be recovered from slag by flotation. However, considering the complex forms in which valuable metals occur in nickel slag, high yields are ...

crushing slag and matter

crushing slag and matter SBM mining equipments applied .. Heavy construction equipment refers to heavyduty vehicles, specially designed for executing construction tasks. They are also known as, construction equipment ...

Crushing Slag And Matter

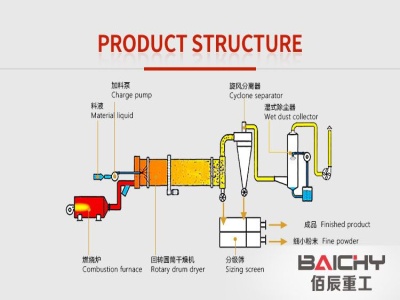

Crushing Slag And Matter. We are a professional mining machinery manufacturer, mainly including crushing equipment, sand making equipment, grinding equipment, beneficiation equipment, ball pressing equipment, can meet any of your requirements, leave a message or consult to get the latest discounted price, hurry up Right.

Quality in sample preparation

CuPb slag (Cu %) 30 g % 50 g % 70 g % EDX spectra showing the Cu peak intensity of the copper matte (green) and the CuPb slag (blue) milled in the same grinding vessel with interposed sand cleaning (test with 30g). The contaminated CuPb slag (yellow) was milled directly after a copper matte sample without sand cleaning.

DIVISION III MATERIALS

Slag shall not be used as an aggregate for Portland cement concrete. For AirCooled Blast Furnace Slag, the Los Angeles Abrasion requirement of is modified to permit a maximum loss up to 50 (FM 1T 096) provided that the amount of material finer than No. 200 sieve generated during the Los Angeles Abrasion test is less than 18%.

slag crushing d

crushing slag and matter Effective Utilization of Induction Furnace Slag by Extraction of Metal using Crushing System 1M. V. Deshmukh, ... Crusher Figure slag D) Separator ... slag is tons/year which is costing around Rs. 11,850. Thereby ascertain power and labor cost for pounding the slag and . crusher slag in us ...

Ground Slag Properties, Characterisation and Uses

mineralogy no matter where it is made in the world. This contrasts with fly ash, where the chemistry is essentially wholly dependent on the nature and relative proportions of minerals associated with the coal matter being burned. Slag lies between these two extremes, with its chemistry being determined by (a) minerals associated with the iron ore, and (b) the limestone added to the melt to ...

Quenched Slag

Aircooled slag can be crushed to coarse and fine aggregate fractions, whilst quenched slag is granular, similar to sand. The impact and crushing values and friction angle of slag are similar to or better than those of the natural aggregate.

An overview of utilization of slag and sludge from steel ...

An overview of utilization of slag and sludge from steel industries B. Das∗, S. Prakash, Reddy, Misra Regional Research Laboratory (CSIR), Mineral Processing Energy Technology Department, Bhubaneswar, Orissa 751013, India Received 29 September 2005; received in revised form 1 April 2006; accepted 24 May 2006 Available online 7 July 2006 Abstract Significant quantities of ...

Crushing Cars Is a Loud, Smelly Business That's Terrible ...

· Crushing Cars Is a Loud, Smelly Business That's Terrible for Air Quality. So take it somewhere else, says Chicago's Southeast Side. Metal crunches and shrieks at .

A Study on Strength Characteristics of Metakaoline and ...

extraction of stone crush aggregate, sand and lime etc as result the environment is getting polluted day by day and creating a matter great concern. In this dissertation work the cement is replaced partially with metakaolin and slag at various %ages respectively, and their corresponding

iron ore slags manufacturer

Crushing Plant Iron Ore Slag Crushing Plant Manufacturer. We are one of the leading suppliers for Iron Ore Slag Crushing Plant and we work closely with our customers to fulfill their specific needs for a customized packaged solution Specialized in the fabriion of these machines for 25 years and this enables us to be in a leading position in the field of Iron Ore Slag Crushing Plant ...

Emission Factors for Abrasive Materials

Abrasive blasting materials, such as coal slag garnet and copper slag, are often used for cleaning metal surfaces to remove rust and to prepare a surface before the appliion of a coating. The preblast and postblast (spent) abrasive materials contain traces of heavy metal constituents such as Cr, Mn, Ni, Pb Fe, and Ba. Hence, the health risk associated with the resultant particulate ...

Latest Posts

- الرسم البياني الخطي الأساسي والثانوي

- تكلفة الكسارة البسيطة من المملكة العربية السعودية

- كسارة الالات النقالة

- معدات تعدين الذهب المستخدمة لأفريقيا

- شاشات اهتزازية دائرية للبيع

- سعر تعدين محجر الحجر الجيري

- مصنع معادن الكوارتز في السعودية

- مسحوق الحجر الجيري مطحنة الكرة

- كسارة الأسطوانة الكسارة رمح التجمع

- شركات تعدين الذهب الجزائر

- lignos sudan فى السودان

- مطحنة الكرة حساب حجم الكرة

- صناعة شاشة الكسارة

- من جهة ثانية محطة كسارة الحجر 200tph في مصر

- طحن البوكسيت الخام

- Mesin Crusher Plastik Bekas Jaw A Timur

- Milling Business In Zimbabwe

- Feed Grinder Machine

- Schema Of Mfl Crusher Mobile

- Mini Stone Crusher Service Manual Pdf

- Small Portabable Brick Crushers

- Mining Equipment Capital Cost Pc

- Cost Of Pe 500750 Crusher

- Mining Quarrying South East Asia Sales Managers Heavy Machinery

- Manual Portable Rock Crusher To Make Sand

- Mini Stone Crasher Image With Price

- Where To Buy Stone Crushing Equipment In South Afr

- Small Scale Diamond Crusher In Angola

- Air Calssifier Manufacturers In China Producing Mm

- Ball Mill Price List In