Batch Plant Aggregate Conveyors

BATCHING AND MIXING

When draining aggregates at the batch plant site, provide provisions for dis posal of drainage water and for clearcut separation of drained from undrained materials. Keep materials of different sources/classes or gradations separated. Sometim es, timber bulkheads are erect ed to save space in the Producer's storage yard. These are satisfactory if built properly. Erect the weighing bins and ...

Concrete Batch Plant Modeling

batch plant: the unloading of aggregate or sand from truck, rail or barge onto storage piles; the movement of aggregate and sand to maintain the shape of storage piles; the process of filling the bucket of the frontend loader for transfer to the hoppers; wind erosion of the sand and aggregate storage piles; and the movement of delivery trucks, cement trucks and frontend loaders over the haul ...

BATCHING AND MIXING

demonstrated that the most uniform concrete is produced when the batching plant is favored by adequate space for the maintenance of large stockpiles of materials. When draining aggregates at the batch plant site, provide provisions for dis posal of drainage water and for clearcut separation of drained from undrained materials.

How Does the Concrete Batching Plant Work? | Kaushik ...

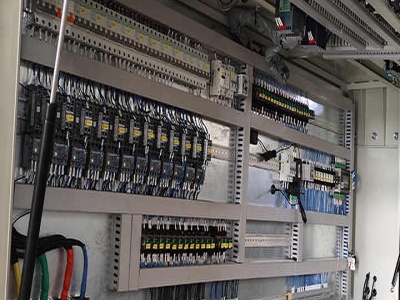

Conveyors; Cement receptacles; Aggregate containers; Chillers; Heaters; Cement storehouses; Batch plant controls; Dust collectors (to limit ecological contamination). The Concrete Batch Plants can be Classified into 4 Sections: Powder feeding; Aggregate feeding; Water; Admixture for blending the materials, transport, and storage. Working: At the point when the control arrangement of the mixer ...

Ready Mix – Stephens Manufacturing

The stationary Stallion aggregate section is constructed of 1/4" steel on sloping sides and 3/16" steel on vertical. The aggregate batcher is 12 yd. and the plant is standard with a 30" transfer conveyor. 36" belt and A/R or poly.

Belt conveyor type concrete batching plant

· Belt conveyor type concrete batching plant use belt conveyor to transport aggregates to the concrete mixer. The main advantages are large conveying capacity, continuously work, .

Chairman Word

CONCRETE BATCHING PLANT (type c) Wet batch plant or wet/Dry batch plants are available. Plant Suitable for Block making. PRODUCTIVITY (Output Capacities) AGGREGATE BINS AGGREGATE FEED CEMENT STORAGE STANDARD MIXER PLANT CONTROL WATER SYSTEM ADMIX SYSTEM 50m3/hr 4 Binsx25T Radial Conveyor 2x60T 1m3 pan mixer Fully Automatic PLC metered 2"line ...

Preventive Maintenance of Batching Plant

Examine the aggregategate pivot points and apply lubricant if required. 3. Monthly Maintenance Checklist. Monthly maintenance checklist of batch plant includes : Examination of the conveyor skirt boards and sealers and their replacement with new ones if required. Stiffening the Conveyor belts and adjust them to correct position.

Sand and aggregate conveyors

Sand Aggregates Conveyors. Affordable sand and aggregates conveyors help improve the efficiency and safety of onsite building and construction materials handling for companies traditionally unable to access such technology... Click to enlarge. This simple but effective conveyors appliion suite is becoming increasingly popular with the small and medium scale building and construction ...

HAGAN LOW PROFILE PORTABLE BATCHING PLANT

Batch Transfer Conveyor: 30" and 36" belt with 35 degree idlers, vulcanized rubber lagged head pulley, selfcleaning wing type tail pulley, ... 60 to 200 ton three and four compartment aggregate bins. Plant is prepiped for air system. Provides fast performance of all air cylinders, vibrators and aeration.

Chairman Word

4 Aggregate Weigh 5 Batch Conveyor 6 Cement Silo 7 Cement Weigh Hopper 8 Mixer . 4 CONCRETE BATCHING PLANT (type b) CONCRETE BATCHING PLANT (type b) PRODUCTIVITY (Output Capacities) AGGREGATE BINS AGGREGATE FEED CEMENT STORAGE STANDARD MIXER PLANT CONTROL WATER SYSTEM ADMIX SYSTEM 50m3/hr 4 Binsx25T Radial Conveyor 2x60T .

Aggregate Handling Systems

Aggregate handling and conveyor systems are available for any concrete batch plant or appliions that require the unloading, storage, and transfer of aggregate materials. From unloading, transfer to storage, and transfer to production, a multitude of systems can be designed to efficiently move aggregate materials at the least possible cost.

ASPHALT BATCH DRUM MIX PLANTS

processes including aggregate storage areas, conveyors, aggregate transfer points, a rotary aggregate dryer, weigh hoppers, asphaltic cement (oil) heating storage, screens, pugmills, product storage silos, drop zones, and haul roads. The dryer, weigh hoppers, pugmill, and asphalt storage silos are typically vented to a common baghouse. Two types of asphalt plants currently exist in San Diego ...

ULCIV

36″ wide conveyor for greater aggregate transfer capabilities. Weighing System. The ULCIV utilizes a combination load cell arrangement to accurately weigh the contents of the given batchers. This consists of four cells per batcher (3000 lbs of cement/15,000 lbs of aggregate) linked to a summing box for interface with a batch control unit.

Conveyor Components

A complete line of conveyor components are available for all areas of your conveyors. Idlers, trough idlers, drum pulleys, bearings, belts, and belt fasteners. CONVEYOR BELT. Primary Sidebar. Find It. Search this website. Secondary Sidebar. Parts Catalog; Full Batch Plant Systems; Contact; Footer. Search this website. Parts Components. Aeration Components; Aggregate Clam Gates; Air .

ConCrete BatCh Plants

productivity of Besser batch plants. Batch plants have earned the reputation as "Heavyweight Performers" in the concrete industries. Independent metering hopper with metering conveyor feeding the block machine Six W2000 model aggregate bins with 30" X 72' (750 mm x 21,600 mm) weigh belt conveyor

Portable Concrete Batch Plant in Kenya

This kind of concrete batch plant is belt type concrete batching plant Kenya, the aggregate are delivered by belt to concrete mixer. 3. It has relatively stable productivity, about 25 m3/h to 60 m3/h, which has a wide field of appliion, is mainly applied in rural and urban construction, roads and bridges construction projects. 4. The whole portable cement batch plant covers a small area. It ...

Conveyors For Sale | IronPlanet

Right Manufacturing Systems Portable Concrete Batch Plant. 2 Bin Portable Aggregate Feeder, 14 in Aggregate Conveyor, Right Manufacturing Systems Tilt Drum Mixer, Right Manufacturing Systems Cement Silo, Portable Hopper, Skid Mounted Hydraulic Power Pack, Perkins Diesel EngineThe engine starts and runs. Go back. View Product. 2006 (unverified) Thor 150' Telescopic Radial Stacking. Seller ...

Concrete Batch, Asphalt Batch, and Rock and Aggregate Plants

or aggregate), conveyors, and dust collectors (, baghouses). 1. The ingredients for concrete are introduced into the mixer where they undergo agitation. This process is typically vented into baghouses to prevent dustemission s. Dryconcrete batch plants do not use water, which can create more dust. Wetconcrete batching usually uses aggregate material that has been washed to remove silt ...

Conveyors and Material Handling Systems

A properlysized conveyor will ensure that your aggregate supply will keep up with your concrete batch plant's maximum rated production capacity. Therefore, the capacity and design of your batch plant will largely dictate your material handling conveyor requirements.

Batch Plants and Towers For Sale

Batch Plants and Towers (15) Blue Smoke Kit (2) Boom Lift Bucket Elevators (6) Burners (38) Classifiers Cold Feed Bins (33) Cold mix and Continuous Mix Plants (2) Complete Asphalt Paving Operations For Sale (3) Compressors (2) Concrete Equipment and CTB Plants (6) Control Houses Controls (39) Conveyors (15) Cranes

Latest Posts

- مطحنة فرس النهر اليمن

- وازم المعدات الحصى فحص

- ريمون طحن أسطواني

- مزود IRO خام المحمولة كسارة في المملكة العربية السعودية

- صانعو آلات طحن غير مركزية مصر

- مطاحن طحن trituradoraata

- المطاحن التجارية الأوروبية

- قائمة أسعار مطحنة الكرة الدورية

- كسارة لفة هيدرولية من مطحنة الانتهاء

- مخروط محطم في مصر سعر لمحطة

- كتالوج كسارة ذروة

- تستخدم مطحنة تكسير الاسمنت المتنقلة

- مطحنة علف للبيع في مصر

- كسارة متنقلة للبيع في اليابان مصر

- من جهة ثانية كسارة في مصر

- Sringwater Paper Mill

- Crusher Batu Gunung

- Spain Used Por Le Crusher For Sale

- Grinding Chili On A Stone Grinder

- Used Static Granite Crucher

- Crusher Plant Developer Cost

- Crusher Machines Price For Pakistan

- 100 Tons Crore Mobile Crusher Mfg In Trinidad And Tobago

- Limestone Grinding Work Index

- What Is The E Traction Process For Feldspar

- Sbm China Products Grinding Mtm Medium Speed Trapezium Mill

- Gravel 038 Sand Supplier In Laguna Phil

- Automatic Sanding Machine Automatic Sanding Machine

- Gas Dryer Sale Los Angeles

- Stone Crushers Sale Dubai