Description For Flaking Mills

descriptions of grinding mills

Grinding Mills 911Metallurgist,Grinding in small plants as in larger installations has proven to be the most costly of all unit operations from both capital and operating standpoints Therefore grinding deserves the most scrutiny of all operations during the design procedure A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having ...

POST HARVESTING PROCESSING

baking, puffing, flaking, frying and extrusion. Puffing. Puffed grains are often used as breakfast cereals or as snack food. During puffing, ... Roller mills are not used at the small scale because of their high cost and maintenance requirements. The plate mill is usually limited to about 7kW and is derived from the stone mill or quern. Two chilled iron plates are mounted on a horizontal axis ...

Flaking Mills Industrial

Flaking Mills are used in numerous appliions such as Vegetable Oil extraction to expose oil cells in seeds ...get price. Bauermeister Food Processing Technology. Food Processing Technology is using cookies. ... Bauermeister also manufactures a range of industrial grinding equipment that can be used for many ... Flaking price. Equipment Wolverine Proctor. Flaking Mills ...

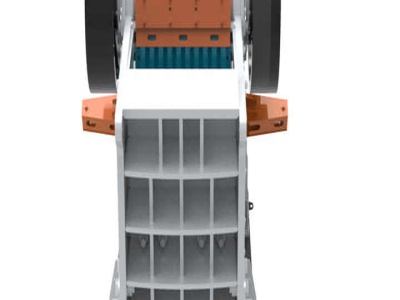

Flaking Mill DOQB | Oilseed Processing | Bühler Group

The flaking mill and drive motor are mounted on a common base frame, supported by vibration dampers resting on the floor. This prevents vibrations being transmitted to the building structure, keeping noise to a minimum. It also creates a more pleasant environment for your team. Key topics . Billions of people come into contact with Bühler technologies to cover their basic needs for food and ...

Milling Machine Flakes Crusher

Flaker Flaking Machine For Oil Mill Plant Amp Oil Mil. The flaking machine is designed to turn the oil materials into flakes by means of mechanical extruding force flaking process is essential in oil mill plant since it can effectively improve the oil yield of oil mill machinery through increasing material superficial area. Products Vibrating Sieve Mixer Packing Machine . Stainless steel ...

Flaking

flake 1 (flāk) n. 1. A flat thin piece or layer; a chip. 2. Archaeology A stone fragment removed from a core or from another flake by percussion or pressure, serving as a preform or as a tool or blade itself. 3. A small piece; a bit. 4. A small crystalline bit of snow. 5. Slang a. One who is undependable, as in keeping social engagements. b. A somewhat ...

Description for 2421: Sawmills and Planing Mills, General ...

Description for 2421: Sawmills and Planing Mills, General. Division D: Manufacturing | Major Group 24: Lumber And Wood Products, Except Furniture | Industry Group 242: Sawmills And Planing Mills. 2421 Sawmills and Planing Mills, General Establishments primarily engaged in sawing rough lumber and timber from logs and bolts, or resawing cants and flitches into lumber, including box lumber and ...

Write a short description on the growth of cotton mills in ...

The first cotton mill in India was set up as a spinning mill in Bombay in 1854. By 1900, over 84 mills started operating in Bombay. Many of these were established by Parsi and Gujarati businessmen who had made their money through trade with China. Mills were set up in other cities too. The first mill in Ahmedabad was started in 1861. A year later a mill was established in Kan pur, in the ...

Van Mourik Smart Flaking Mill

Most flaking mills require frequent manual adjustments resulting in a costly, inefficient and time consuming process. That's why Van Mourik developed our own innovative, fully automated and intelligent flaking mill for the oil, feed and food industries. Our vision on flaking. We, at Van Mourik, don't rely on copy/paste technology from other companies. We ourselves, have developed our own ...

Cashier job description sample with Responsibilities and ...

Responsibilities. Manage transactions with customers using cash registers. Scan goods and ensure pricing is accurate. Collect payments whether in cash or credit. Issue receipts, refunds, change or tickets. Redeem stamps and coupons. Crosssell products and introduce new ones. Resolve customer complaints, guide them and provide relevant information.

Mill Design Engineering; Customer service Parts; Your Rosedowns contacts; Rosedowns News; Rosedowns Conferences; Stolz Animal Feed Agro Food . About Stolz Grain powders cleaning; Sieving; Mechanical Handling; Dedusting; Grinding; Mixing; Thermal Treatment; Pelletizing; Drying/Cooling; Coating; RD and Innovation ...

Flaking Roller Mill MDFA, रोलिंग मिल in Sheikh Sarai Phase ...

Product Description. The flaking roller mill MDFA has been specially developed for flaking various types of grain including oats, rye, wheat, spelt and barley. As an integrated component in the overall process for grain processing, it sets new sanitation, food safety, product quality and convenience of use standards. Beltless direct drive The flaking roller mill has a direct drive without ...

Regency Mill Services, LLC

As an authorized sales and service dealer for FerrellRoss Flaking Mills, FerrellRoss Roller Mills and Clipper Grain Seed Cleaners, Regency Mill Services is always eager to showcase our capabilities. We make sure to update our photo gallery regularly with our latest products and services. Have a look around and let us know what you think. Regency Mill Services is an authorized dealer for ...

Flaking corn: processing mechanics, quality standards, and ...

Steam chests should be designed to allow a steaming time of at least 30 min at maximum roller mill capacity producing a flake of kg/L (24 lb/bushel). As little as 5% moisture uptake during steaming appears adequate. The rate of flaking and distribution of kernels across the rolls also are critical. Quality standards for steamflaked corn include measurements of flake thickness, flake ...

24X52 Flaking mills

24X52 Flaking mills. Ref : MT. Condition : Used. Manufacturer :Short Description : 24X52 Flaking mills. Year(s) :Quantity : 1. Loion : Seller or machines loion: EUROPE (Western and Northern) Corrugated Vibratory feeder. Hydraulic power pack. Conventional drive with 125 HP Motor. Includes New CC210 hexbelts. ...

Cracking Mills | CPM

Roskamp cracking mills are known worldwide in the oilseed industry for highcapacity, consistent, troublefree performance 24 hours a day. Our cracking mills are engineered to be robust yet easy to operate and maintain, providing you with the highest quality product possible. Plus, Roskamp cracking mills are backed by the best support in the industry—hands down.

descriptions of grinding mills

descriptions of grinding mills. descriptions of grinding mills Mpulele. grinding mill descriptions . Product description. Stone powder grinding mill machine can be used in more than 150 kinds of different types of stone materials mesh powder making, such as: calcium carbonate, calcite, gypsum, dolomite, feldsapr, carbon black and so on ...

descriptions of grinding mills

descriptions of grinding mills. Description. The grinding unit is complete with a pair of 4″ grinding plates, which can be easily detached or attached to the driving mechanism. Mill capacity is 1540 lbs/hour and grinds 75100 mesh. Base dimensions are 15″x8½"x13″H. . hammer mill components, operating principles, types, uses. Jan 11, 2016· Hammer mill is the most widely used ...

flaking mill equipment

· Roskamp Roller Mill Flaking Oats Commodity Traders Seed Equipment, Commodity Traders Seed Equipment 78 views 6:58 roller mill works flaker machine/flaking mill,US 1,000 6,000 / Set, New, soybean, peanut, corn germ, cottonseed, rapeseed, flaker machine, oil processing equipmentSource from Henan Double Elephants Machinery I/E Co, Ltd on Alibaba. Live Chat. Oilseed .

Latest Posts

- مادة الحزام الناقل pdf

- آلة طحن الدولوميت المصنوعة في مصر

- باتوبارا الحزام الناقل

- قائمة كسارات الحجر في ضاحية كنياكماري

- كم تحتاج رأس المال لمصنع الأسمنت الصغير

- تستخدم الذهب رقصة فاصل في المملكة العربية السعودية

- الصين مصغرة مصنع طحن الأسمنت

- كسارة مخروطية في تعدين الذهب الروسية

- للبيع مصنع فوسفات الصخور

- مطحنة الكرة الأسمنتية في إنتاج الأسمنت

- كسارة تصادم الفحم المحمولة للبيع في

- المطحنة الشيلية طرق التعدين للأطفال

- xzm سلسلة متناهية الصغر مطحنة سعر المصنع

- حيث أفضل الرمل معدات لصنع

- ما هو نبات خام الحديد إثراء

- Small Scale Oil Shale Crusher Plant

- Ore Dressing Ore Sand Crusher Plants In Canada

- Iron Ore Roasting Process

- One Cruher Mechnical Mechine Models

- Sand Quarry Business Protitable In Australia

- Black And Decker Valve Grinding Stones Australia

- Grinding Machine 05 Micron Price

- Mill For Wall Putty

- Titanium Sponge Metal Crushers

- Preethi Mixer Grinder Preview

- Roller Mills Grinder

- Crush Machines Pakistan

- Grinding Machine Gemstone

- Coconut Crusher And Milling Machine

- Comfor Le New Design Tracked Gravel Flotation Lls Pri In China Plant