Separator For Raw Mill

Tender For Replacement Of Raw Mill Separator Body Tender ...

· CCOIL Tender For Replacement Of Raw Mill Separator Body Impeller Assembly Separator Internals With Necessary Fabriion Work And R, Due Date: ,Tender Value: 0,City :, Loion: Himachal Pradesh Tender Notice

separator in vertical raw mill

High Efficiency Separator For Raw Material Ball Mill. High efficiency dynamic separator 21 pages p this type of feed allows less space to be taken up and use in vertical grinding mills or airswept ball mills 247 online why separator fan is use for cement millhy separator fan is use for cement mill the sepol highefficiency separator plays a key role in feed material reject ball mill.

separator unit used in the raw mill

Cement mill Wikipedia. These have been used for many years for the less exacting rawmilling process, but recently roller mills, in combination with highefficiency separators, have been used for cement grinding. The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient.

Best energy consumption

· For raw grinding with relatively dry raw materials, the combination of the roller press and V separator is a viable alternative with far lower mill fan power. Cement grinding For cement grinding, the technology development away from ball mills has taken a different route.

Ghorahi Cement orders raw mill and coal mill

I and, instead, to produce the cement raw material for both kilns in the new, large vertical mill. The new MVR 5600 R4 will be producing 525 t/h of cement raw material. This raw mill with a grinding bowl diameter of m will be by far the largest mill ever delivered to Nepal. It will have a drive power of 5350 kW and come equipped with a ...

Implementation of Lean in Raw Mill Separator Air Slide to ...

· The paper presents the method to implement lean in the raw mill separator air slide, an equipment used in cement industry. Lean is a philosophy that .

separator in vertical raw mill

Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the regrinding; powder while grinding out with air, dust collection equipment in the system

mineral processing

mineral processing mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill. In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated. These properties can be colour (optical sorting), density (gravity separation), magnetic ...

Processing Options Pricing | Vermont Fiber Mill

If you want the fallout from the separator returned to you, please indie this in the Add'l Information section on the Work Order form. Separating: /lb/pass. Dehairing Cashmere: 20/lb/pass. Carding: The carder is the heart of the mill. It aligns the individual fiber strands to produce roving and batts that may be used as final ...

separator in vertical raw mill

Vertical Raw MillVertical MillChina Sunlike . Currently, the vertical raw mill has become quite mature in raw materials grinding The features of our vertical raw materials grinding mill are as follows: 1 The separator comes with a variety of structures, thus assuring the raw roller g

working separator raw mill in

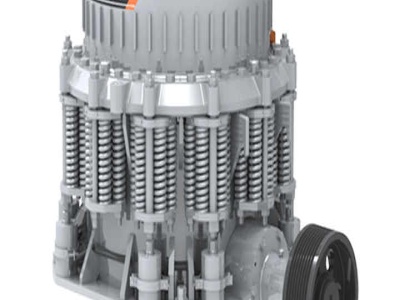

working separator raw mill in . GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirements.

DAGONGMEGA CERAMIC MACHINERY

From grinding media(alumina ball)to ball mill, from magnetic separator to spray drier, DAGONGMEGA successfully integrates ceramic raw material processing system to provide a full range of professional services for customers. MORE. NEWS — 2019 CERAMICS CHINA FAIR. . 2019 Indian Ceramics Fair. . 2018 Italy Rimini Ceramic Fair. . HAPPY NEW .

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

Separation air at separator outlet : 5599 m 3/min Separator vent air at bag filter outlet : 210 m 3/min − The velocity of gases calculated through mill is m/sec. This velocity is sufficient for OPC33 grade grinding. − The separation air at separator measured as .

working of separator raw mill in cement factory

· separator for raw mill working – Grinding Mill China. cement mill seperator. working of separator raw mill in cement factory – process crusher. The Gulin is the professional mining equipments manufacturer in the world. Read more . ATOX ™ raw mill880 Кб. Working principle The ATOX raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind ...

Vertical roller mill

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure ...

raw mill separator fan

Raw Mill Separator By Negative Pressure balieieper cement separator in grinding mill For raw grinding with relatively dry raw materials the combination of the roller press and V separator is a viable alternative with far lower mill fan power Cement grinding For cement grinding the technology development away from ball mills has taken a. Rawmill Wikipedia . A raw mill is the equipment used to ...

Highefficient cement manufacturing with POLYCOM® and ...

11 Example of a Polysius plant layout of a raw grinding plant with feed hoppers and connection of kiln gases. 12 Example of a Polysius plant layout of a finish grinding system. For cement grinding, the highpressure grinding roll (HPGR) POLYCOM ® and the staticdynamic separator SEPOL ® PC can be installed as a finishgrinding circuit or, in combination with a ball mill, as a combi ...

Latest Posts

- الكروم المغناطيسي الجزئي

- عملية الحصول على الركام في المباني

- آلة حجر محطم رونينغ على

- كسارة فكية مستعملة في هيوغو الجزائر

- مصانع محطم في تصنيع جنوب جا

- نوع مطحنة الحجر

- آلة طحن أوراق من السودان

- mini milling تايلاند العلامة التجارية mubea

- الكسارات أثر astec

- مطحنة الكرة مصنعين في مصر

- الكرة مطحنة لخام الحديد الولايات المتحدة الأمريكية

- المواصفات لمحطة كسارة

- planificar una trituradora pdf

- مقاطع من مطحنة طحن الكرة الاسمنتية

- صخرة كسارة مطرقة مصر

- Tramming Of Crushed Ore

- Civil Used In Rackcrasher Machine In Different Company

- Compare Compare Prices On Cutter Grinding Machines

- Stone Crusher Plant Cap T H Price

- Marble Cutter Machine Price

- Raymond Of Cgm Machinery With Technical Specification

- Australian Underground Mining Standards

- Charcoal South Africa Jaw Crusher Equipment Dealer In Tamilnadu

- Cement Plant Crusher Layout

- Natural Sand Pool Filter Size Mm

- Second Hand Floor Sanders For Sale

- Crusher Jaw Machine Working Photo

- Micro Grinding Mill Machine Bangalore

- Stone Production Line For Sale

- Farval Lubrication Systems Mexico