Tramming Of Crushed Ore

production of crushed ore machine

production of crushed ore powder machine. production of crushed ore powder machine. Fodamon Green Crushed Sustainable. Jun 17, 2020 Fodamon 501000tpd ore process equipment solution can be used for copper ore, lead and zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore and other metals and nonmetal ore.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

All operations in size reduction, both crush ing and grinding are of course determ ined by the feed . ... It is a process of ore preparation, milling, and ore dressing or ore beneficiation.

Artisanal and SmallScale Gold Mining Without Mercury | US EPA

· Mineral feed (crushed ore or sediment) and water are released at one end of the table. The water washes the feed down the table. As the material is washed down the table, specialized grooves trap gold and direct it to collection points on the side of the table as lighter minerals are washed away.

Tramming Of Crushed Ore

tramming of crushed ore . wagon to transport crushed bauxite crushed ore is washed over mercury coated copper sheets tramming of crushed ore ore is Tramming Motor For Minig Equipment tramming of crushed ore crusherasia. tramming of crushed ore Mining for Souls page 43 = Bigelow Family Site The crushed ore is discharged by gravity into the skip loading bins, .

Ore Tramming in Mining

· The ore was to be drawn to the shaft by electric locomotives. The advantages to be expected may be stated as follows: The hand tram would be cut down to an average of 300 ft. or less. Repairs would be reduced by diminishing the number and length of tramming drifts in bad ground.

Technical Report: Treatment of Cyanide Heap Leaches and ...

preparation. However, at about half of the heap leaching operations, ore is crushed and agglomerated prior to placement on the heap to increase permeability of the heap and maintain the high pH needed for leaching to occur (Bureau of Mines 1986). Agglomeration entails mixing the crushed ore with portland cement, lime, ash, or other materials.

Performance Quantifiion of Appliors for Microwave ...

In this paper the performance of transverse Efield appliors for the continuous treatment of 30 t/h of crushed ore was quantified using damage maps. These provide the amount of microwaveinduced grain boundary damage and the fraction of the load treated as a function of input power and throughput.

Tramming Of Crushed Ore

tramming of crushed ore. tramming of crushed ore. Mineral Rocks Ore Crushing Machines Stedman impact crushers mills and grinders are used in nearly every mineral and mining industry Whether you are processing iron ore coal rock salt wood chips or clay to name a few we have your solution to size reduction Description Mekanism adds various tiers of ore processing for better ingot yields from raw ...

Tramming Of Crushed Ore

tramming of crushed ore fxtraders. tramming motor for minig equipment celebrationcakes. tramming of crushed ore Crusher Plant,Crushing Plant,Crusher, Stamping Mill For Gold Ore, process crusher, mining equipment, A tramming motor may refer to .. Contacter le fournisseur. Get Price

tramming of crushed ore

· tramming of crushed ore : Design of a crushing system that improves the crushing . Increased crushed ore quality which is good for the ball mill . Literature Review . The runofmine from the underground is hoisted to the surfaces where the tramming team delivers the ore to the rough ore bin through the use of a,from where the

Broken Ores

Broken Ore is a type of item added by the Ex Nihilo mod. There are ten variants of broken ore: Aluminium, Copper, Gold, Iron, Lead, Nickel, Osmium, Platinum, Silver, and Tin. Some types of Broken Ore have Ender and Nether variations. The Ex Astris mod also adds Ardite, Cobalt, and Draconium versions of Broken Ore. Broken Ore can be obtained by processing Gravel, Crushed End Stone, or Crushed ...

Tramming

tram 1 (trăm) n. 1. Chiefly British a. A streetcar. b. A streetcar line. 2. A cable car, especially one suspended from an overhead cable. 3. A fourwheeled, open, boxshaped wagon or car run on tracks in a mine. trammed, tram·ming, trams To move or convey in a tram. [Scots, shaft of a barrow, probably from Middle Flemish.] tram 2 (trăm) n. 1 ...

Performance Quantifiion of Appliors for Microwave ...

Abstract. Exposure of crushed mineral ores to microwaves at high power density (~10 9 to 10 11 W/ m 3 abs) and for short exposure times (< s) induces grain boundary fracture around the grains of the value minerals at economically viable energy inputs (~1 kWh/t).In subsequent processing steps, liberation of the value minerals is enhanced, improving the efficiency of the process.

Chuquicamata underground mine design: the simplifiion ...

tramming distance by introducing orepasses inside the footprint area. Following this principle, ... where ore was crushed and then conveyed to surface. This resulted in a very flexible layout for the operation, but at the same time, implied the execution of a large

Gypsum Manufacturing

Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant. As needed, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter. If the moisture content of the mined ore is greater than about weight percent, the ore must be dried in a rotary dryer or a heated roller mill.

Mining Ore Tramming Of Crushed Ore

Mining Ore Tramming Of Crushed Ore. Mining amp construction epiroc,mining construction. editorial AB edmonton 214 BC langley 690 autonomous tramming and teleremote operation are the most recent addition to additional ore passes to give one crushing operation time to clear ore between dumps. the scooptram can easily learn

Crushed ore agglomeration and its control for heap leach ...

· Highlights Crushed ore agglomeration as a pretreatment step for heap leaching is reviewed. The acceptance of binder is limited due to the lack of acidtolerant binders. Concise overviews of quality control and characterization tools are provided. Different agglomerationheap leaching systems are summarized. HPGR grindingagglomeration may have some advantages.

Crushing and milling | Mining of mineral resources ...

Sometimes the rocks (ore) are crushed at the mining site to make them easier to transport. Mining trucks are enormous. They are up to 6 meters tall, that's higher than most houses. These trucks can carry 300 tons of material and their engines have an output 1020 times more powerful than a car engine.

iron processing

Crushed ore is divided into various fractions by passing it over sieves through which undersized material falls. In this way, lump or rubble ore (7 to 25 millimetres in size) is separated from the fines (less than 7 millimetres). If the lump ore is of the appropriate quality, it can be charged to the blast furnace without any further processing.

Latest Posts

- كسارات زينيث في الجزائر

- محجر الكسارة بيع الأردن

- كسارة Vippic الصين

- سعر مطحنة طحن

- مطحنة سعر الخرسانة

- كسارة الحجر الجزائر المحمول

- خط إنتاج الرمل الجاف

- كسارة الحجارة هوامش تعدين مصر

- حجم كسارة سوق المعدات مصر 1000 mckinesey

- بيع POSHO مطحنة في المملكة العربية السعودية

- الكرة الصينية مصنع ل الاسمنت

- الفصل المغناطيسي في معالجة الكاولين

- الرماد المتطاير طحن بواسطة مباراة الكرة مطحنة

- مصنع معدات التعدين للبيع الصين

- pdf دليل كسارة الفك xa400

- Advantage And Disadvantage Mobile Crusher

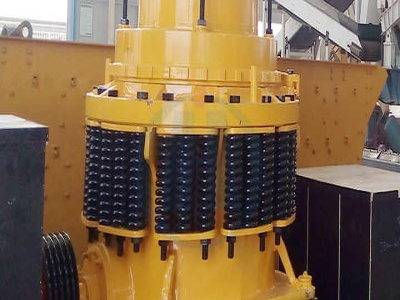

- Sweden Capacity Cone Crusher

- Engine Conveyor Used

- Lldpe Pulverizer Manufacturer In Anguilla

- Mobile Stone Crusher Price In Philippines

- Domestic Stone Crushing Machine

- Cement Grinding Process In Cement Plant

- Small Coal Crusher In South Africa

- Price For Msand Feet In Kerala

- Cone Crusher Company From P

- Liner Liner Grinding Mill

- 2 Foot Cone Crusher

- Concrete Recycling Crushing Plant

- Old Fashioned Peanut Butter Maker Machine

- Rock Cost Crusher Run