Ball Mill Pot Pmp

The operating principle of the ball mill

· The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

Big Ol' Stands

Dragon Ball ZeroTwo Horn Heart Empty Heart X Soul Chill Hat Doom Hellmet Someone's Glasses Someone's Hat Bunjolio Diary Dio Diary Pot's Diary Bootleg Diary Heck Diary Samurai Diary Infinity book Pot's Arrow Bootleg Arrow Lucky Arrow DIO's Skull Pro Orb Blindfold Purple hat

Milling Jars | Paul O Abbé

The mill jars are rotated with the aid of a jar rolling mill, which has two rollers to support and rotate the jars at the proper speed. The milling jar is half filled with grinding media or balls from ¼" to 1" and as the mill rotates the solids are trapped between the ball and are milled down to as little as 1 micron by the cascading and tumbling action of the ball charge.

An Efficient OnePot Synthesis of New 2 Thioxo and 2oxo ...

· (2014). An Efficient OnePot Synthesis of New 2 Thioxo and 2oxopyrimidine5carbonitriles in BallMilling Under SolventFree and CatalystFree Conditions. Phosphorus, Sulfur, and Silicon and the Related Elements: Vol. 189, No. 2, pp. 235241.

The Secret to Perfect Terra Sig

· I recently traded emails with Jim Gottuso, of Sofia's Dad's Pots fame, about how to make Terra Sig using a ball mill. His recent blog posts about Sig made me realize I should post my Sig information (Click here to see his post). My base is Pete Pinnell's well circulated recipe, which I .

Green HighYielding OnePot Approach to Biginelli Reaction ...

A simple, green, and efficient approach was used to synthesize 3,4dihydropyrimidines derivatives. We showed that the appliion of the planetary ball milling method with a balltoreagent weight ratio of 8 for the Biginelli reaction provides 3,4dihydropyrimidines derivatives with excellent yields (>98%) in a short reaction time from the onepot, threecomponent condensation of aldehydes ...

When using planetary ball mill, how to select ball size ...

· When using planetary ball mill, how to select ball size and how much material should be taken in mill pot? The ball size chosen depend on the impact energy requirement. Bigger balls help in size reduction if the feed particles are big like chunks. If the milling materials are powder, then smaller ball size is preferred. There should be at least ...

One‐pot in situ ball milling preparation of polymer ...

A one‐pot method which involves peeling graphite nanosheets (GNs) off into graphenes in polymer solution and in situ forming polymer/graphene sheets nanocomposites by using ball milling is presented. Via this approach, nanocomposites based on maleic anhydride grafted poly (ethylene‐co‐vinyl acetate) (EVA‐g‐MAH) and graphene sheets comprising one to five layers were .

alumina ceramic mill pot ball pot

Alumina ceramic pots mill Grinding jarCS Ceramic Co Ltd ball mill pot manufacturers suppliers and exporters on. Electrical ceramic magnetic material pigment and dope special cement porcelain enamel and glaze ect industrial line Used in material crush one part of ball grinding mill Specifiion table of ceramic grinding pot Alumina Ball Wholesale Various High Quality Alumina Ball Products from ...

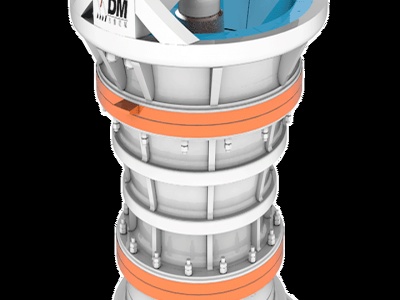

Barrel Mills/Pulverizers | RSE Projects

Read more about our Single Pot Barrel Mill, 3 Pot Barrel Mill as well as our 6 Pot Barrel Mill. Pot barrel mills are particularly suitable for rapid, lossfree grinding / milling of hard, brittle and fibrous metallurgical materials for analytical fineness.

FeCl3‐Mediated One‐Pot Cyclization–Aromatization of ...

· A straightforward and efficient method has been developed for the solventfree synthesis of 2,4diphenylquinolines via a onepot reaction of anilines, benzaldehydes, and phenylacetylenes promoted by FeCl 3 under solventfree mechanochemical ball milling. Using this protocol, a series of 2,4diphenylquinolines were synthesized in good to excellent yield (74–95%) just by washing the .

Mini Lathe Modifiions

Move the pot back to the original setting and repeat this process for the other 2 pots until you get a good sense of how they affect speed and torque. After you play with them for a while in various combinations you should find a setting which provides a low speed of 3050 RPM with good torque. 30 RPM is the slowest speed I have been able to achieve with adequate torque.

Grenades Archives

Excellent Condition WW2 British Mills Grenade. £ Add to basket Details.

Fritsch GmbH

· Planetary ball mill Up to 2200 rpm bowl speed Final fineness down to more The halfprice particle size analyzer: Save money on analyzing powders, bulk solids suspensions Measurement range 5 µm – 20 mm Modern software Individual image analysis in microscopy quality Fast evaluation Optional wet dispersion unit more

KannaMill® hemp processing equipment

KannaMill ® hemp processing equipment has been designed in partnership with high production hemp processors. At the heart of every KannaMill ® is our long history of manufacturing rugged, durable equipment. Our heavyduty, precision designed equipment meet the demand for low maintenance and tight particle size distributions in the finished product.

Laboratory Equipment Manufacturers in South Africa | RSE ...

RSE Projects supply modern, cutting edge equipment that is aligned with your exact requirements. Our roots lie within the materials handling industry and across 3 decades, we have expanded to supply high quality General Laboratory Equipment to a range of core industries across Africa, from Cement and Mining to Water Purifiion and General Laboratories.

Ball Mill Repair

Ceramic Ball Mill Repair. AB Industrial Ceramics is a South Carolina based supplier and installer of wear resistant ceramic linings and media in the ball mill industry. We own a complete line of equipment to handle small and large jobs in either the ceramic or refractory fields.

Laboratory Mills | Milling Jars | Laboratory Ball Mills ...

Laboratory ball mills are scaleddown ball mills that use milling jars that are filled with grinding media and rotated using a jar rolling mill to reduce the particle size of the material. While they are commonly used for small size appliions, options are available that .

Zirconia Ceramic Ball Mill Pot

The mill pot produced by gongtao company have monolithic construction,big round arc mouth of pot can be sealed and opened easily,tight seal,beautiful sculpt,hard and phenomena such as gap,leak,material stock,dead space ect can not occur in Gongtao company can also offer you rock bottom price for 65% al2o3 ceramic mill pot.

Common Basic Formulas for Mineral Processing Calculations

· Pulp Densities. Pulp densities indie by means of a tabulation the percentages of solids (or liquidtosolid ratio) in a sample of pulp. This figure is valuable in two ways—directly, because for each unit process and operation in milling the optimum pulp density must be established and maintained, and indirectly, because certain important tonnage calculations are based on pulp density.

Pot of flour

An empty pot spawns in the Cooks' Guild which contains a mill, though the guild requires 32 Cooking and a chef's hat for entry. Pots of flour can be obtained for free by searching an oak larder (or a higher tier larder) in a playerowned house. For members, this is significantly faster than creating flour from grain. Quest usage [edit | edit ...

Latest Posts

- كسارات فكية صغيرة الحجم مستعملة للبيع في دبي

- مصنع معالجة الذهب الصخرية

- البعد القدرة كسارة الفحم 75 الهيدروكربونات النفطية

- كسارة فكية صموئيل أوزبورن

- معدات إنتاج الذهب

- الجرانيت سعر كسارة

- نموذج تأثير كسارة

- شراء كسارة الصخور

- التكنولوجيا الحديثة في المطرقة مطحنة

- حالة الفك محطم عمان العملاء شركة

- معدات الطحن لتعدين الذهب على نطاق صغير

- كسارة الفك للبيع الجزائر صغير

- تقنيات كسارة المحاجر

- الصين آلات الطين مسحوق الختم

- plc استنادا سحق الفحم ووصف الناقل

- Causes And Effects Of Common Deseas In Stone Quarry Communities I Ghana

- Zenith V Crusher Spec

- Bl Jaw Crusher

- Micron Mill Wave Table Patents

- Crude Coal Tar Distillation Manufacturers

- Symmons 4 4 Cone Crusher

- Build A Ball Mill For Digger

- Cara Membuat Grind Stone Ran Online

- Raymond Grinding Can Grind Coal Ash

- Cryogenic Grinding Mills Crystal Crusher For Natural Quartz Stone

- Stone Crushing Plant Manufacturers Saudi Arabia

- Cement Paste Settling

- Good Perfoermance Ball Mill

- New Gold Ore Dressingprocessing Equipment

- Zhengzhou Xinguang Mining Machinery Manufacturing Co Ltd