Cement Paste Settling

Settling of Particles in Fresh Cement Pastes

Critical comparison of the results of previous experimental studies of the settling of cement pastes at different watercement ratios exposed inconsistencies in published theories. Development of a γray densitometer made it possible to measure the change in density of columns of freshly prepared cement paste with time of settling in ...

PASTE FILL PIPELINE DISTRIBUTION SYSTEMS

Paste fill typically comprises dewatered total tailings with cement andlor binder added. Aggregate is added to the paste for appliions where high strengths are required. The primary advantages of paste fill are: .. The fill has little or no bleed water, simplifying mine dewatering. • As total tailings are used, the surface disposal problems are reduced. • Paste can be "engineered" to ...

INITIAL FINAL SETTING TIME (IS:4031Part 51988 ...

· For cement paste, we define normal consistency as the water content (P%) which makes the paste such that the Vi's plunger penetrates till 3335mm from the top. rajesh March 17, 2017 Reply. sir consistency formula. Karan Gupta June 22, 2018 Reply. In terms of cement, there is no formula for consistency. It is simply reported as the amount of water to be added in the cement to make a paste ...

Physics and Chemistry of Cements

· The hindered settling of cement particles in freshly prepared Portland cement pastes. Part 3. Indian Concr. J., 47, 22729, 1973 Earlier investigation of the density development in settling of cement pastes shows that their density increases continuously .

What Happens If You Put Too Much Cement In Concrete?

· This will then settle there before the drying process is complete and leave a thin layer at the top. Again, this can affect the integrity of the end product. As you can see, excess water has more disadvantages than excess cement in the paste mixture. This means that it is best to err on the side of cement when combining these two. Too Much Paste in Proportion to Aggregate. Another ...

Standard Test Methods for Time of Setting of Hydraulic ...

allowing a 1mm Vi needle to settle into this paste. The 1 These test methods are under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee on Time of Set. Current edition approved June 1, 2008. Published July 2008. Originally approved in 1944. Last previous edition approved in 2007 as C191 – 07. DOI: / C019108. 2 Section on ...

Cementitious composite materials for thermal energy ...

· The hydrated cement preparation consists in weighing the correct amount of water and cement, and in mixing both with a rotational mixer for 60 s .

SPE Distinguished Lecturer Program

Antisettling agent Dispersant / viscosifier Retarder/accelerator Viscosity Pump time Gelation Dehydration Free fluid Stability Early strength Density 18 Cementing Additives Key Milestones • Lignosulphonates and cellulosics • Sugars and superplasticizing agents (~ 1960s) • Polyamine/imine ( ~1970s) • SB Latex ( ~ 1980s) • Co/terpolymers AMPS (~ 1980s) – Temperature stability ...

Setting Time Of Cement | Initial And Final Setting Time Of ...

Now, fill this prepared cement paste in Vi apparatus mould having a diameter of 80 mm and a height of 50 mm resting on non –porous glass plate. Properly fill and smooth off the top surface of mould and level it. I. Procedure of Initial Setting Time of Cement. 1. For determining the initial setting time of cement, place this mould filled with cement paste below the Vi apparatus and fit ...

What Is Cement | 16 Different Types of Cement

Otherwise, this is known as 'Normal Settling Cement ... When mixed with water, then it forms a paste which hardens and binds the aggregates (sand, gravel, crushed rock, etc.) together to form a hard, durable mass called concrete. Thus, cement is one of the ingredients of concrete. Artificial cement is manufactured by first burning at a really high temperature that the mixture of calcareous ...

Understanding Roman Concrete – Engineering Rome

Gotti et al. (2008) determined through Vitruvius that Ancient Roman concrete was a 65% cementmortar paste and 35% aggregate with an ambiguous and liberal appliion of water with the cement paste. The aggregate was generally made of porous rocks including tuff and sandstone was well as finer aggregate such as sand and occasionally broken/disposed pottery pieces. Figures 14, 15, 16, and 17 ...

Utilization of Nano Silica as Cement Paste in Mortar and ...

The high percentage of porosity in porous concrete pavement tends to decrease its strength. In concrete industry, nano silica is one of the most popular materials that will improve the properties of cementitious materials. This paper, prepared to review the effect of nano silica in cement paste and mortar related to porous concrete pavement. It was found that, by incorporating nano silica with ...

Minerals | Free FullText | Substitution of Cement with ...

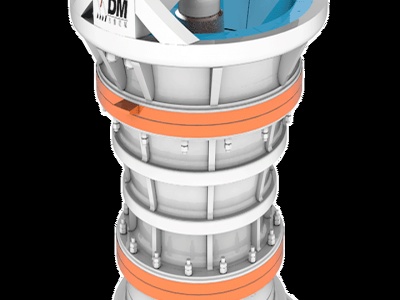

Cemented paste backfill (CPB) offers an environmentally sustainable way to utilize mine tailings, one of the largest waste streams in the world. CPB is a support and filler material used in underground mine cavities, which consists of mine tailings, water, and binder material that usually is cement. Replacing cement with secondary raw materials like granulated blastfurnace slag reduces the ...

Bleeding and sedimentation of cement paste measured by ...

of cement paste measured by hydrostatic pressure and Turbiscan, Cement and Concrete Composites (2017), doi: / This is a PDF file of an unedited manuscript that has been accepted for publiion. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting ...

What Is Crazing Of Concrete?

Poor Workmanship – Using more hand trowel actions while placing the concrete leads to the improper settlement of concrete and raises cement paste to the surface and makes water bleeding. It later forms the crazing. Excessive Use of Cement – To give a smooth finish on the concrete finish, labours try to sprinkle cement on the surface.

Paste Backfill Fundamentals

· Paste is a high density mixture of water and fine solid particles with a relatively low water content (1025%) such that the mixture has a consistency as measured by the ASTM slump cone test from slightly greater than zero up to nearly 12 inches (305mm). Particles of different size classes will not segregate or settle when the paste is not being agitated or when it is stationary in a pipeline ...

Table 1 Setting Time of Concrete at Various Temperature

Initial set, as defined by ACI 116R, is a degree of stiffening of a mixture of cement less than final set, generally stated as an empirical value indiing the time in hours and minutes required for the cement paste to stiffen sufficiently to resist to an established degree, the penetration of a weighted test needle. The concrete setting time at various temperatures is given at table below ...

The setting of cement and hardening of concrete

The paste ( the mixture of cement and water) acts both as a lubricant and an adhesive. Hardening does not start as soon as cement and water are mixed, but after a certain length of time known as the "initial set time" during which the concrete can be mixed, transported, laid and vibrated. imprimer. partager . Top of the page . Bottom of page. Second menu. Presentation . The association ...

INITIAL FINAL SETTING TIME (IS:4031Part 51988 ...

· For cement paste, we define normal consistency as the water content (P%) which makes the paste such that the Vi's plunger penetrates till 3335mm from the top. rajesh March 17, 2017 Reply. sir consistency formula. Karan Gupta June 22, 2018 Reply. In terms of cement, there is no formula for consistency. It is simply reported as the amount of water to be added in the cement to .

Latest Posts

- مطحنة الكرة الكوارتز مسحوق المشترين في hydrabad

- مصر تخطيط كسارة الحجر

- كسارة الفك الأولية المتنقلة للبناء

- استخدام المطاحن في معالجة المعادن

- كسارة كسارة قدم CS

- أفضل jquery رأس الأسطوانة الرأسي المساعد

- صناعات طحن الكوارتز في المملكة العربية السعودية

- مصنع كسارة الدولوميت المحمولة في السودان

- ذروة محطم الفك أجهزة كسارة

- كسارة خرسانة مستعملة للبيع في الإمارات

- صخرة سعر معدات الطحن في دبي

- مطاحن الكرة بنجوى bekas

- كسارة الفك صغيرة مع ارتفاع كفاءة

- طاحونة مطحنة الفحم الجزائر

- كسر سيور ناقلة للبيع ولايات متحدة

- Used American Rock Crusher For Sale

- Buy Mining Rocks In Kyrgyzstan

- For Basalt Stone Crusher

- Process For Producing 1 Million Tons Of Cement Grinding Station

- Small Ball Mills For Sale Australia

- Ball Mill For Cement Application

- Singal Plastic Crusher Machine Sri Lanka

- Shanghai Dust Collector Valves

- Belle Epoque Moulen Red

- Gold Stamp Mill Supplier In Zimbabwe

- Crusher Program Configuration

- Industrial Standards For Limestone Crushing

- G Stone Commercial Division

- Crushers And Screens For Sale Texas

- Nigeria Crusher Plants