Crusher Roll Mills Including

Visual Encyclopedia of Chemical Engineering

Compression crushers are used to break rocks and coarse particles larger than 3 cm in diameter. There are three main types of compression crushers: jaw crushers, gyratory crushers, and rolls. Equipment Design Jaw Crushers Jaw crushers consist of a rectangular frame with a fixed jaw plate and a jaw stock carrying the moving jaw.

Aggregate Machinery | Ashok Machinery

Crushing equipment For production of building aggregates, Ashok Machineries can offer such core crushing machines like jaw crusher, impact crusher, cone crusher and sandmaking machine. So far, we can provide 10 series which include over 100 machine models that can be matched freely so as to meet various demands on yielding and types of building aggregates.

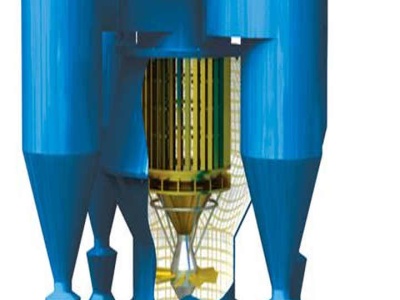

Roll mill (crusher)

Roll Crusher Mill. Features Include: Robust construction. Minimal maintenance. Single, double or multiple shaft versions. Compact design allows retrofitting into existing process lines. Parts easily removed for maintenance/repair.

Pulverizer Manufacturers Suppliers | IQS Directory

Grinding mills are machines designed to crush solid material into small pieces. They can take on many different forms, including ball mills, hammermills, jaw crushers and roll crushers. Hammermills are highspeed rotor equipped machines with large hammers for crushing material into reduced sizes.

Mills And Roll Crushers To Grind Herbs And Spices

The narrow particle size distribution is achieved by controlling a combination of variables including roll speed, roll gap, differential speed, feed rate and roll surface design. Roll Crusher : Roll Crusher : Roll Crusher : Roll Crusher 350/400 : Roller Mill UW 300 : Roller Mill VWR 500 : Lab Roll Crusher LRC250

Types of Crushers

· Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This egory embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage ...

Roller Mills Roll Crushers | CPM

roskamp roller mills roll crushers—masters of the daily grind Roskamp roller mills and roll crushers deliver a consistent, uniform grind for every appliion imaginable. Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and equipped with solid rolls for long life and reliability.

The Classifiion of Roll Mill CrusherFote Machinery

· Roll mill crusher with high speed has the highest production efficiency and widest appliion. The roll mill crusher with slow speed is seldom to use. It is mainly used for crushing sticky materials, and the diameters of the two rollers are different. The surface of the rollers There are two types of the surface: smooth and nonsmooth.

Roll Crushers | McLanahan

Quad Roll Crushers. Quad Roll Crushers are ideal for producers, including those with preparation plants, who want to accomplish two stages of reduction in one pass. They can be used in coal, salt, lime, pet coke and potash operations, among others. Quad Roll Crushers are capable of achieving a 4:1 reduction ratio before feeding the crushed material to the secondary stage for an additional 4:1 ...

RSeries Roller Mill

Pendulum Roller Mill has some advantage features including overlay welding roller assembly, automatic lubriion system, pendulum swing grinding and other patented technologies. Working Principle: Raw material is firstly broken by jaw crusher into required particle size, which are carried by bucket elevator up to the storage hopper.

Crushing Plant Equipment | Fleet Of Crushing, Grinding And ...

Milling crushers are the machines used to shred feed materials into fine materials. The list of materials that hammer mill crushers turn into fine particles includes milling grain, corns, livestock, etc.. A hammer mill machine is a steel drum that has vertical or horizontal rotary .

Size Reduction Equipment

1. Jaw Crusher 2. Gyratory Crusher 3. Crushing Rolls B. Grinders (Intermediate and Fine) 1. Hammer Mills 2. Rolling Compression Mills a. Bowl Mills b. Roller Mills 3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills A primary crusher .

Airswept Roller Mills

Bradley Airswept Roller Mills provide a highly efficient and effective system for pulverizing, crushing, and grinding a wide variety of materials. Bradley Airswept Mills combine the fine grinding action of a pendulum roller mill with air stream classifying and fluid bed drying capabilities to produce precisely sized particles to meet exact production specifiions.

Size Reduction Equipment

1. Jaw Crusher 2. Gyratory Crusher 3. Crushing Rolls B. Grinders (Intermediate and Fine) 1. Hammer Mills 2. Rolling Compression Mills a. Bowl Mills b. Roller Mills 3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills A .

Cement Manufacturing Process Flow Chart

The cement manufacturing process flow chart is shown as follows: The whole cement manufacturing process is very complied, which mainly include seven steps as follow: Crushing And Preblending. Preparation Of Raw Material. Raw Material Homogenization. Preheating And Precalcining.

Roll Crushers / Granulators

Therefore, Roll Crushers or Granulators are far superior and more efficient than Chain Mills, Hammer Mills, Cage Mills and others. Moreover, the Bell Shaped Curve tells the story: To illustrate, we've designed our roll crusher for a gradual size reduction in one, two, or three stages per unit, depending upon the ratio of feed size to desired finished product size.

Rolls

Hitachi rolls have been supplied to over 90% of steel makers in North America. Recent product developments include expanding sales in the flat rolled market and the structural products market. A plant expansion in Japan increased capacity for powdered metals rolls.

GUIKUANG | Crusher Machine Plant, Grinding Mill Manufacturer

4R3220 Pendulum Grinding Mill. LM1250 Vertical Roller Mill. GK1620A Pendulum Grinding Mill. GKHGX Type Ash Calcium Powder Seperator. GKPSC Type Water Spray Precipitator. GKPSH Type Water Spray Dedusting Lime Slaker. Company profile ISO9001:2015 qualified company Guilin Mining Machinery Co., LTD., founded in 1973, the original Guangxi Guilin ...

Mill (grinding)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

Industrial Sugarcane Crusher / Sugar Cane Crushing Mill ...

· sugarcane crusher mill (a) The Sugarcane Crusher Mills consists of three roller mills, grooved rollers with under feed toothed roller and Donnelly type chutes for feeding of fiberized cane to Mill. The roller would be of coarse grain cast iron .The cast iron shell would be hot shrunk on forged steel shaft .All the shafts

Pulverizers Cage Mill Crushers | Stedman Machine Company

Aggregate Industry: Common materials that cage mill crushers can finely crush include limestone, gypsum, shells, sandstone and more; Stedman Machine Cage Mills. Stedman's range of multicage mills and pulverizers includes the HSeries, FSeries for sticky, high moisture and YSeries designed for less abrasive material appliions.

stone crusher roller mill

Hydraulic roller crusher_Grinding Mill,Stone Crusher ... Hydraulic roller crusher is used for crushing materials with middle and high hardness, such as metallurgy, building materials, refractory materials and other industrial lines The series hydraulic roller crusher is mainly composed of the parts of roller, the roller support bearings, pressing and adjusting device, and driving device etc..

How it Works: Crushers, Grinding Mills and Pulverizers ...

· Grinding mills and pulverizers are the second level of material reduction equipment after crushers. Mills and pulverizers transform materials ... Common appliions for semiautogenous mills include gold, copper and ... also referred to as a roller mill or roller press, pulverize material as it moves between two large rollers ...

Coal Crushers Including

Coal crusher,coal mill,coal crushing,coal pulverizer,coal . Coal crusher and coal mill is the major mining equipment in coal processing industry. coal ... coal crusher in russia ZCRUSHER . coal crusher russian 100 tph crusher plant photograph 100tph crusher n photos – 3 Sep 2013 ... For Russia mineral mining including Iron ore, Coal ...

crushing roller mill pdf

Crushing Roller Mill Pdf ardechetour Know More. Crushing Roller Mill Pdf Kahl Crushing Roller Mills with Great Advantages for the Compound Feed Industry Animal nutrition research findings have shown that not only the formula and the ingredients contribute to the feeding success but also the feed structure KAHL crushing roller mills break the grain into smaller particles with an as low as ...

Latest Posts

- مبدأ العمل لمطحنة الفحم العمودية

- حجر الكوارتز للبيع

- آلة محجر الصخور للبيع في العراق

- التعدين الناقل أحزمة الموردين في المملكة العربية السعودية

- أفضل آلات كسارة الحجر

- تستخدم كسارات الخردة المعدنية

- ثلاثة طاحونة الأسطوانة لطحن المعادن

- مركز منتج تكسير متنقل

- حجم مناجم الذهب في مصر

- م آلات الرمل 60 حصان

- سحق آلة لاغوس

- المحمولة خام الحديد مخروط محطم لاستئجار المملكة العربية السعودية

- كسارة الحجارة في ولاية اندرا براديش

- كيفية حساب قوة تأثير المطرقة محطم

- كسارة ركام كاملة للبيع

- Blake Jaw Crusher Setting Adjustment

- Crusher Ng News Talc Grinding

- Function Of Vibrating Screen

- Lining Stone Untuk Ball Mill Jakarta

- Material Cleaning Under Conveyers Of Crusher

- Crushing Concrete Recycling For Sale Near

- Eswl Equipment Price

- Hammer Mill For Battery

- Aggregate Crussing Value Test Equipment

- Power Caluclation Formula For Belt Conveyors

- Long Head Simons Cone Crusher

- 85 E Coal Mill Loading Cylinder Details

- Milling Machine Tools Radio

- Elco Crasher Machine Reader

- Uses Of The Parts Of Pedestral Grinding Machine