Aboboras Iron Ore Processing

Iron Ore Concentration

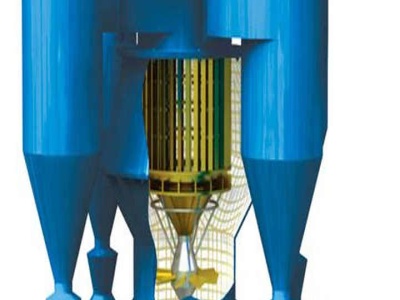

Iron ore concentration equipment from Multotec has been designed to increase the percentage of valuable iron ore extracted from your concentrate. Multotec's core business is around supplying products and services to the mineral processing industry. Our aim is to reduce capital and operating costs, increase uptime and, essentially, optimise mineral processing procedures. Multotec's equipment ...

Modeling and Simulation of Iron Ore Sintering Process with ...

Modeling and Simulation of Iron Ore Sintering Process with Consideration of Granule Growth Bin ZHANG, Jiemin ZHOU, Mao LI* and Yuan LI School of Energy Science and Engineering, Central South University, No. 932, Lushan South Road, Changsha City, Hunan Province, 410083 P. R. China. (Received on June 27, 2017; accepted on September 26, 2017) Granule growth is an important .

BENEFICIATION OF IRON ORE

Main types of iron ores 6 Hematite 6 Magnetite 6 Resources/Reserves of iron ore deposit in India 7 Processing of Iron ore in India 8 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI

A Comparative Study on Characterisation and Processing of ...

Processing of Iron Ore Slimes S. Roy and A. Das MNP Division, National Metallurgical Laboratory, Jamshedpur Abstract Beneficiation of iron ore slimes has been studied. Three different iron ore slimes from Chitradurga, filling and Ukraine have been characterized in detail. The slime samples have been beneficiated with a view to produce a sufficiently enriched concentrate. The Chitradurga iron ...

(PDF) Kenyan Iron Ore: Mining and prospects of processing ...

Kenyan Iron Ore: Mining and prospects of processing Prof. S M. Maranga* and Alvin Kiprono Bett* and Kyalo Ndeto* and Gilbert Bett** *Jomo Kenyatta University of Agriculture and Technology (Department of Mechanical Engineering) **Wanjala Mines Abstract Industrialization is one of the economic pillars in the Kenya Vision 2030 thus iron and steel will be prominent in the industrialization process.

Iron Ore Technical Centre

The ALS Iron Ore Technical Centre has been designed and built to accommodate scalable fused bead XRF processing capacity in excess of 10,000 samples per day. With specialist expertise in processing hematite, magnetite and all forms of iron ore, the centre provides extensive ore characterisation,

Iron Ore Processing | Home

Kiruna, the northernmost city of Sweden, is home to an iron ore mine of the same name, which processes and stores pellets. These iron ore pellets are transported from Sweden to Norway for shipping. In 1902, a train line was built all the way to Narvik for this purpose. At the time this was the most northern train line in the world. The trains using this route pull up to 68 rail carts and ...

Iron Ore Pelletizing Process: An Overview

Bentonite is an effective, widely used binder in the iron ore pelletizing process. Its low price is an important factor for its extensive use. However, bentonite incorporates silica and alumina, which are undesirable contaminants to pellets. Additionally, it is a natural material with variable composition depending on its origin. Obtaining a suitable binding effect requires a relatively large ...

::MECON

Mine production process capacity enhancement of all iron ore mines of NMDC Ltd. (Bailadila complex Donimali) EPCM for beneficiation plant (2 MTPA) at Bacheli slurry pipe line (15 MTPA) for Bacheli to Nagarnar plant. HINDUSTAN COPPER LTD. Computer aided pit optimization, stagewise mine planning, grade estimation, revision of ultimate pit layout, estimation of balance mineable reserves (2 ...

Iron ore pelletizing

This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being disposed of. Iron Ore Pellets are formed from beneficiated or run of mine iron fines. The iron is usually ground to a very fine ...

Kiruna Iron Ore Mine, Sweden

Ore processing takes place in three concentrating plants and three pelletising plants. The mine produces more than 75,000t of iron ore a day. The processed iron ore products are transported to Narvik port via the Malmbanan and Ofotbanen mine railway lines. Completed and ongoing projects at the Kiruna mine . Although the 1,045m haulage level was originally expected to serve the mine until at ...

Tutorial:Automated Ore Processing

Iron Ore Pulverized Iron: 2 ... An advanced Ore processing facility will use at least 3 of these Machines, one for each main alyst (there are several speciality alysts not covered here). The Induction Smelter is particularly recommended for the following Ores, listed by alyst used: Sand . Produces 2 Metal Ingots from an Ore and 2 Ores from a Nether Ore. It is the alyst used to ...

Home Page

Welcome to National Iron Ore Mining Company . THE FEDERAL GOVERNMENT OF NIGERIA (FGN) began to show interest in the establishment of an Iron and Steel Industry in the country as far back as 1958 – well before the advent of the oil boom period. Thus, having realized and accepted the importance of steel in the Technological Advancement of the Nation, the FGN by Decree No. 19 of April 1971 ...

Processes and Procedures in the Extraction of Iron ...

· The extraction of iron from its ores is quite a technical process. The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace. These materials are loaded into the blast furnace from the top while a blast of hot air is introduced into it from beneath via small pipes known as tuyeres.

Ironmaking Process

· D. Zhu, in Iron Ore, 2015. Summary. The BF ironmaking process is currently the dominant process for providing steelmaking raw materials worldwide. However, the BF process relies heavily on metallurgical coke and involves cokemaking and sintering operations, which often attract serious environmental concerns. Therefore, DR and SR technologies using noncoking coal or other .

Dry Iron Ore Beneficiation | Iron Ore Separation

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits. STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale). Significant movement of iron and silies was observed, with examples highlighted in the table below. The results of ...

China aims to increase selfsufficiency on iron ore with ...

· In light of this, a group of scientists has set the goal to increase selfsufficiency in iron ore. The main reason behind China's dependency on imported iron ore is that the country's iron ore is relatively lowgrade and expensive to process. Ever since 35yearold Sun Yongsheng acquired a doctorate in mining science six years ago, he has ...

Ore processing

· A Macerator processes ore iron, gold, copper, tin, lead, and uranium into 2x crushed ore of the corresponding type. It does not process (as of ) ores for coal, lapis, diamond, redstone, emerald, or nether quartz. Crushed ore can be smelted into ingots (except for uranium). Stage 2 . An Ore Washing Plant processes crushed ore into purified crushed ore (using 1000 mB of water .

Geochemical characteristics of iron ore deposits and ...

· Iron ore available in this area is of lowgrade haematite and while the laterite has shown highest grade of % to the lowest grade of %, with an average grade of % (Table 2). This grade of iron ore is useful for steel making (ICE Report .

Iron Ore Processing Flowsheet

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a substantial part of good quality material is rejected in the form of slimes. The other plants use wet screening are being used to produce better and stable quality lumps of iron ore ...

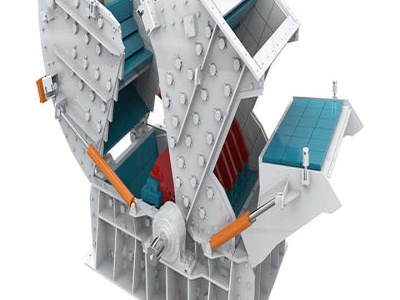

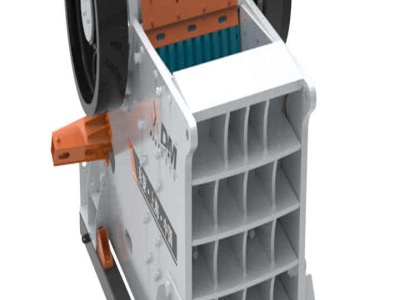

The Six Main Steps of Iron Ore Processing | Multotec Canada

· When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is .

iron ore Archives

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and . Read more. Hematite Processing by Flotation ...

Ore Processing

Ores of chemically pure materials can be processed in of Ingot for 1 Ore ( Iron), ores of chemically compound materials can be processed in 1 Ingot for 1 Ore ( Tetrahedrite). Hint: throwing a stack of items in Cauldron will consume as much Water as 1 item thrown in there at a time. Primitive Blast Furnace . In a new method of ore processing become available for new ...

Iron Ore

· Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its production.

Latest Posts

- جودة كسارة الصدم للبيع

- المملكة العربية السعودية الكرة مطحنة التصنيع

- معدات تعدين خام النحاس في اليمن

- جوز الهند مصر جاك هيدروليكي

- حجر صغير للبيع

- مصنع تكسير الجرانيت البرازيل

- شاشات عالية التردد فى مصر

- صور تعدين الفحم تحت الأرض في مصر

- التعدين الأساسية المصنعين الحفر

- كسارة مخروطية tc الجزائر

- مصانع طحن الأسطوانة الأفقية

- رمل السيليكا لوضع nj الأخضر

- كسارات تستخدم لانتاج بيع الرمل فراك

- مطحنة كسارة متنقلة

- التكيف الحديثة من آلات طحن

- Eagle Wash Screw Wear Plates

- Universal Mill Output 120t H

- Hammer Mill X Yellow

- Words In English Extraction Of Gold

- New Mining Equipment Pictures

- Black Powder Ball Mills

- Machinery Machinery For Stone Crusher

- Penggilingan Batu Gerinda Dan Setting

- Jaw Crusher Typical Feed Size

- Ball Mill 2 Tonnes Per Hour

- Prolonging Cone Crusher Liner Life Crusher For Sale

- China Supplier Milled Rice Moisture Meter Grain Moisture Meter

- Miningpanies In Canada With Online Contact

- Ballmill Magnetite Crusher For Sale

- Cedar Rapids Shaker Screener Manual