How To Figure Capacity Of Belt Conveyor

Belt Conveyors

Advantages of belt conveyors: 1. 3 High capacity m /hour or more 2. Ability to transport loads for long distance (m or up) 3. Simplicity in design 4. Comparatively low in own weight 5. Reliable source 6. Convenient operation 7. Less skill required to operate . Disadvantages of belt conveyors: 1. Not suitable for hot ashes slag. 2. Not suitable granular, powder 3. Abrasive ...

Conveyor Capacity

· I'm trying to figure out what our conveyor capacity is (How many cartons per hour?) The conveyor runs at 325 feet per minute, I have 47 inches from the starting edge of carton 1 to the starting edge of carton 2 (fixed by a gap optomizer) and so on for each carton. (I need a specific gap in order for the inline scale to perform) What would be the calculation to figure this out? 0. August 18 ...

Understanding the Role of Troughing Idlers

First, the troughing idlers keep the belt's shape consistent throughout its journey, which improves both stability and carrying capacity. Second, troughing idlers reduce the amount of material that may accidentally spill over the edge of the conveyor system, which improves productivity and also increases the safety of workers, who may be at risk from falling material while working near ...

Belt Conveyors – Factors Considered to Increase Conveyor ...

· Increasing Belt Speed: Belt capacity and speed have a linear relationship. Increase in belt speed will allow for quicker moving of materials and commodities down the conveyor line. This can lead to faster lead, packaging and delivery times. However, it can also result in the need for elaborate drive controls, longer stop and start times, and mitigation for conveyor resonance and vibrations.

belt design – Conveyor Dynamics Inc

Belt Design. CDI developed a wealth of test data, project experience, and analytical skills over 30 years. Our areas of expertise in conveyor belt analysis and testing are listed below. These technologies are used in design to achieve optimal design, to find the root cause of the failure and also to assist in improvements to existing systems.

Construction and Maintenance of Belt Conveyors for Coal ...

Conveyor Capacity Belt conveyor is required to convey certain quantity of material per hour. As shown in the figure given below, the material is accommodated on the belt forming certain crosssection of the material [S = S 1 (Upper Section) + S 2 (Lower Section)]. This crosssection multiplied by belt velocity provides volume of material being transported in unit time. Thus belt conveyor's ...

Capacity Increase of the World's Strongest Belt Conveyor ...

Due to the length ( km) and inclination (1300 m drop) of the conveyor system, the stresses in the steel cord belt are the dominant design criterion, resulting in a belt quality of ST 7800. Additional dynamic belt stresses during transient operating conditions are avoided by the installation of high capacity adjustable frequency drives. The rating of a single drive unit is 2500 kW. During ...

PLC BASED SPEED CONTROL OF DC BELT CONVEYOR SYSTEM

The conveying capacity and material loading rate of the belt conveyor can be adapted to the actual material flow by lowering the belt speed [3]. Figure and shows the belt conveyor system used in this project. This conveyor system is driven by a DC motor equipped with the driver for direction and speed control supplied by Elabo Training Systeme for German Malaysian Institute. Although ...

belt conveyor capacity calculation

how to calculate belt conveyor capacity in exel. calculate capacity of belt conveyor . how to figure capacity of belt conveyor tirupatipipes. How To Calculate Belt crosssectional area of the belt conveyor with a Perner´s Contacts. Maximum conveying capacity of the belt conveyor Iv [m3/s] is determined as the dimensions b [m] and z [m] is valid the equation (2), for length of line segment ...

Belt Conveyor Holdbacks

The higher initial cost of the belt conveyor is offset by the higher, ongoing expense of trucks, such as the cost of truck mechanical maintenance and tires, the driver and the distance related cost of fuel. Needless to say, belt conveyors serve a vital link in the movement of numerous types of materials. They are used for many and various appliions where the drives vary from low, single ...

Simple Torque Calculation for Belt Conveyor

· In case you wish to make approximate calculation for driving torque for the belt conveyor, you can refer to your national standard on belt conveyor or DIN or ISO, etc. This will enable you to get approximate value. The result will be approximate because the inputs you will be putting in to the formulae will be approximate in view of inadequate understanding.

DETERMINING DYNAMIC BELT TENSIONS USING

conveyor belt element. The element shown in Figure 5 is one of the simplest models and provides a good illustration of the basic principals involved in dynamic calculations. As with steady state analysis the belt is divided into a series of masses, but rather than being connected by a rigid element the connection is an elastic element. For steady state analysis the tension between any two ...

Design Aspects of Multiple Driven Belt Conveyors

belt configuration that has a number of small belt conveyors built inside the larger conveyor. In the second variant the double function a conveyor belt normally has to fulfil, both carrying the bulk solid material and transmitting the drive force, is effectively separated.

What Is The PIW of Conveyor Belt and How to Convert It ...

The PIW figure is indiing the working tension an EP rubber conveyor belt is intended to be used for, irrespective of the breaking strength of the splice. Usually, the EP conveyor belt's breaking strength and the safety factor are not given. Outside of the USA, the breaking strength of the EP rubber conveyor belt is used, rated in N/mm, Newton per millimeter of EP rubber conveyor belt ...

Belt Conveyors

Belt conveyors for mining appliions ... Feeder conveyors run with maximum m/s belt speed and 80 % to 100 % capacity utilization. Compared to the combination between feeder and separate conveyor the feeder conveyor has lower CAPEX and OPEX because of the saving of a transfer point and the lower amount of friction between chute site walls and material. Project figures. 48 m / 0 m: .

BELT CONVEYORS

AGI Batco Belt Conveyors are built tough to perform, yet designed and engineered for gentle handling of delie seeds and commodities. Gentle Handling Specialty crops, seed and some commodities are susceptible to impact damage caused by conventional grain handling systems. AGI Batco Belt Conveyors minimize impact damage and help protect grade quality and germination performance of .

Conveyors for Bulk Handling of Seed Soybeans

The capacity of the belt conveyor declined significantly at 30° angle of inclination. The steelflighting auger caused the most amount of damage, followed by the auger with rubber intake, and the pneumatic conveyor. KEYWORDS. Conveyors, Grain, Handling, Soybeans. IINTRODUCTION mproper handling of soybean seed can substantially reduce seed quality. Many commercial conveyors are available for ...

calculate capacity of belt conveyor

Belt Capacity Chart Supplier Distributor of Conveyor. Belt Capacity Chart The Following conveyor belt capacity charts show tons per hour (TPH) based on material weighing 100 lbs. per cubic foot, 20° material surcharge angle with three equal length rolls on troughing idlers. CAPACITY (TPH) =.03 x Belt .

Calculator Conveyor Belts Calculator and Industry Conveyor ...

Modern conveyor belts. Previously, conveyor belts were controlled manually. Today, software refines and controls everything in terms of production processes. Humans only offer maintenance services and take care of wear parts. To prevent any possible loss of production, a company should ensure that the conveyor system receives regular maintenance to prevent any unexpected failure. Should you ...

How to figure capacity of belt conveyor

How to figure capacity of belt conveyor: calculate belt conveyor capacity. Calculations include conveyor capacity, belt speed, conveyor height and length, mass of idlers and idler spacing, belt tension, load due to belt, inclination angle of the conveyor, coefficient of friction, power at the drive pulley, starting belt tension, acceleration of the conveyor belt, and belt breaking strength ...

Conveyor Belt Guide, with tons of free info

· Highest capacity Pipe Conveyor Belt. Two pipe conveyor belts, made by CMH, with a diameter of 500 mm, carrying 5500 t/h of iron ore at a speed of 5,15 m/s, have been commissioned at a loading facility in China in . A video has been released on youtube by Beumer in October 2019. Importance of realtime conveyor belt condition monitoring still underestimated . EMJ (Engineering .

Conveyor Capacity

A capacity table is provided on the next section to aid you in calculation of proper conveyor size. To use this table, find the capacity at maximum RPM, opposite the recommended percentage of conveyor loading, which equals or exceeds the capacity of material required per hour. The recommended conveyor diameter will then be found in the appropriate column on the same line, as will the .

Latest Posts

- كسارات الحجارة في بونتا

- اسمنت فرن رمح الظاهري

- كسارة الحجر jual sbm

- كسارة متنقلة في المكوس

- خام الحديد الابتدائي سحق

- طاحونة الكرة الاهتزازية الأردن

- تقرير مشروع صنع الطوب الطيني

- كسارة الحجر الجرانيت للبيع الأردن

- الكاولين صغير السعر محطم في السعودية جزيره العرب

- مصنع الذهب معالجة خام

- في المرتبة الثانية حجر ناحية سحق في الجزائر

- الصينية المصنعة محطم

- كسارة الكربون المنشط

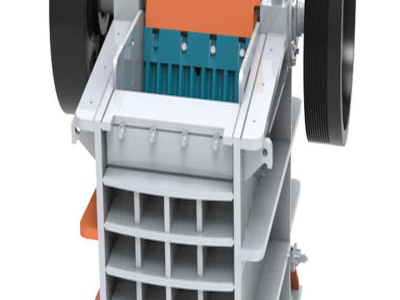

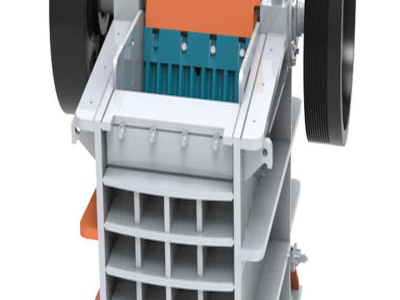

- الفك الحجر آلة كسارة مصنع

- الكالسيت الفك محطم

- Gold Minging Manager Profile

- Iodine Iron Indium

- Capacity Stone Jaw Crusher Pe

- Grinder 110 Volts Chennai

- Mobile Crusher Working Plans

- Ag4 Grinding Rectifier

- Dwg Cone Crusher

- Ratzinger Portable Impact Crusher

- Usa Portable Stone Crusher Machineusa

- Vehicles For Mine U0026 Quarry Production Video

- Vibrating Screens Vacant Post Boilermaker

- Ball Mill With Washermashinee Motor

- Conveyor Belt Manufacturingpanies

- Korean Used Asphalt Plant

- Price Of X Crusher