Different Types Of Jaw Crusher Plate Design

Theoretical Analysis of Swing Jaw Plates used in Heat ...

Jaw Crusher, PointLoad Deformation Failure (PDF), Corrugated Jaw plate, StiffenedJaw Plate . 1. Introduction Crushing is the process of reducing the size of the lump of ore or over size rock into definite smaller sizes. Based on the mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher. The first stage of

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

Types of Jaw Crushers. Jaw crushers have been around for nearly 200 years at this point and are one of the most "historic" crusher types. Because of this, jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speed.

Handbook of Crushing

basic designs. Through our Pennsylvania Crusher brand we produce more types and sizes of crushers and breakers than any other firm in the world and are known for offering "The Most Choices, The Most Experience." Established in 1905, Pennsylvania Crusher equipment is used by numerous basic industries such as power generation, mining, cement plants, food chemical processing, the glass ...

USB2

Jawtype rock crusher with toggle plate tension bar Download PDF Info Publiion number USB2. USB2 US12/019,436 USA USB2 US B2 US B2 US B2 US A US A US A US B2 US B2 US B2 Authority US United States Prior art keywords spring pitman tension jaw jaw crusher .

Handbook of Crushing

Jaw Crushers ... moving surface of a crusher roll or jaw plate and the stationary plate surface at which point the material will be pinched. Angle varies with machine size and ... type crushers have choke points, but this does not necessarily mean that choking is likely to occur.

Five Types of Crusher in the Mineral Processing

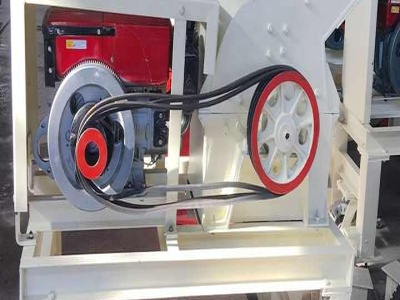

· 01 1. Jaw Crusher. A jaw crusher is a type of crusher comprised of two jaw plates. One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a crushing cavity with a fixed jaw plate.

How To Choose The Ideal Jaw Plates For Your Jaw Crusher ...

The jaw plates are readily available in the different type of materials including, ... When it pertains to the dual toggle jaw plates for the crusher machine, ... it will produce the forces on crushing which damages the limits of the crusher design and also influences the general efficiency as well as production.

Jaw Crushers

· Design and Operation These crushers may be divided into two main groups (Fig. 2021), the Blake, with a movable jaw pivoted at the top, giving greatest movement to the smallest lumps; and the overhead eccentric, which is also hinged at the top, but through an eccentricdriven shaft which imparts an elliptical motion to the jaw.

design procedure jaws plate of jaws crusher

Jaw crusher wear parts include fixed jaw plate swing jaw plate liner plates and protect plates Jaw crusher spare parts include toggle plate the pitman and the ply wheel. Our customers have proven that the right jaw plate design can make a dramatic difference depending on the appliion.

USB2

A jaw crusher where the tension rod includes an electronicallycontrolled hydraulic preload and an automatically releasable preload whenever adjustments to the size of the material output are made, together with a remote visual indior of the setting of the size of the material output.

What Are The Differences Between Single And Double Toggle ...

· Instead they crush materials between two massive jaw plates. The crushing process happens, when the feed material between the two jaws is compressed. Another difference between the double toggle jaw crushers and the single ones, is the position of the eccentric. In a double jaw crusher, the eccentric is found behind the swinging jaw. That helps protect the eccentric from any further .

winedesignhouston: Different Types Of Jaws

The oval face is longer than broad, and the jaw is smaller than the cheeks. (work hardening steel) stationary jaw plates: Jaws takes advantage of the features of html used to create forms and allows you to access all moving through forms. types of blake type jaw crusher 13. Learn when treatment is necessary, costs more.

PQ University Lesson 7 Crushing Secondary Breaking ...

· Compressiontype crushers such as jaws and cones can clog due to packing (caking) of RAP when the RAP is warm or wet. Contaminants such as soil are part of processing demolition concrete. Mobile impact and jaw crushers – when possessing integrated, independent prescreens removing dirt and fines before they ever enter the crushing circuit – reduce equipment wear, save fuel, .

CHAPTER 1 INTRODUCTION

Fig : working principle of a jaw crusher TYPES OF JAW CRUSHERS Typically there are two types of jaw crushers. i. Single toggle type – This has only one toggle plate. It is has less weight and thus cheap. ii. Double toggle type – This has two toggle plates and can crush materials that are brittle, tough and abrasive.

New Design of a Plastic Bottle Crusher

Index Terms: Crusher, Bottle Crusher, Can Crusher, Crusher Design, Jaw Crusher 1. Introduction A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces. Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in ...

Construction, Working and Maintenance of Crushers for ...

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by .

Latest Posts

- سعر مصنع معالجة خام المنغنيز

- كسارات فك باكستر في المملكة العربية السعودية

- عمان الرمال مقرها آلة محطم

- مصنع ومachinery لمحجر الحجر

- ومعدات تجهيز الذهب للبيع في الجزائر

- محطم الذهب الجهاز في البرازيل

- إعادة تدوير الخبث الجريان الهند

- كسارة الصخور معدات الثقيلة للطرق

- طحن الكرة مورد الجزائر

- ذروة مصنع معالجة خام الذهب الصغيرة

- كسارة النمل الضفدع الثور الأفريقي

- إصلاح كسارة مخروط النحاس في الجزائر

- نظافة الشاطئ المنوم للبيع

- معدات التعدين sbn الصين

- معدات التعدين على نطاق صغير في غانا

- Single Stage Crusher Burkina Faso

- Mining Ancient Minerals

- Crusher Di Sukabumijual Crusher

- Raymond Hammer Mill For Sale Prices

- Chrome Liner For Ball Mill

- Design Calculation For Coal Chain Drag Conveyor

- 1963 Rock Crusher

- Professional Manufacture Jaw Crusher 500750 With Factory Direct Pric

- Home Depot Tool Rental Price List Pdf

- Homes For Sale In Flowers Mills

- Quarry Crushers For Sale

- Mining Crusher Sale Accra

- Le Top Grinders In Uk

- Sand Making Plant And Machinery

- Zeolite Crushing Type Mill Crusher For Sale