Working Of Ball Mill With Gypsum And Clinker

CLINKER GRINDING IN CEMENT PRODUCTION

· Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules are formed. Clinker and gypsum (about 5 %) are mixed and finely milled to obtain cement. Gypsum control the setting properties of the cement. It can be partially replaced by other forms of .

What is Cement Clinker? Composition, Types Uses

Gypsum added to and ground with clinker regulates the setting time and gives the most important property of cement, compressive strength. It also prevents agglomeration and coating of the powder at the surface of balls and mill wall. Some organic substances, such as Triethanolamine (used at wt.%), are added as grinding aids to avoid powder agglomeration. Other additives sometimes used are ...

Clinker And Gypsum Going In Ball Mill

Clinker And Gypsum Going In Ball Mill Clinker And Gypsum Crushing Mill A cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cementmost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. Get Price. Zith Ball Mills Gypsum ...

gypsum wet ball mill ball mill

Ball mill used in cement industry for grinding gypsum, cement clinker Ball mill work together with the Good,resources and raw material types for ball mill with,It can grind various materials in dry or wet grinding method Working principle of gypsum grinding mill 1Ball mill(rod mill) main component is a cylinder with Buy Now Ball . gypsum wet ball mills Wet ...

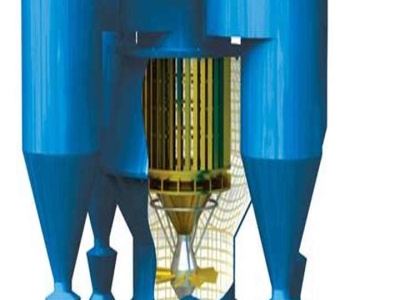

Cement Roller Press, Roller Press In Cement Plant

The ball mill noise is above 110 dB, while the roller press is about 80 dB. Small size, light weight, small footprint, easy installation, and can be installed as a whole. Note : Due to the large force of the roller of the roller press, the roller press has some problems, such as the material and the wear of the roller surface, the bearing is easily damaged, and the gear of the reducer is ...

Dipl.Ing. Th. Fahrland, Dr.Ing. K.H. Zysk, Loesche GmbH ...

Clinker Gypsum Limestone Product Ball mill system Vertical roller mill system Figure 3: Alternative flow sheets using vertical roller mills and ball mills Characteristics Ball mill (closed circuit) Vertical roller mill Comminution by Impact and attrition VRM. CEMENT INTERNATIONAL 4 2/2013 4 VOL. 11 Grinding pressure . VRM. Vertical roller mill ...

Effects of alternative calcium sulphatebearing materials ...

· Prior to the mill start, sufficient warming up operation is carried out to pass the hot air to the mill by using hot gas generator, after that hot gas generator is stopped and source of hot gases is the used clinker temperature itself but in our trial hot gas generator was kept in operation to rise the outlet temperature to 120 °C to increase gypsum dehydration inside the mill. So, the outlet ...

Portland Cement Clinker

At most manufacturing plants the ball mill is used to grind the clinker and, since the production rate is directly related to the amount of electrical energy supplied, the power of the electric motor used to turn the mill is a firstorder measure of the output achieved. Mills vary in their power input from as little as 200 kW up to 10000 kW. An efficient mill system grinding a Portland cement ...

Clinker And Gypsum Grinding Mills

Working Of Ball Mill With Gypsum And Clinker. Vertical Cement Grinding Mill Gypsum rolvaplast. vertical cement grinding mill gypsum proadd. Traditionally, ball mills are used in finish grinding, while many plants use vertical roller mills. In ball or tube mills, the clinker and gypsum are fed into one end of a horizontal cylinder and partially ground cement exits from the other end. Get Price ...

Home

Daily clinker ground with Gypsum (Clinker taken hourly. A composite sample Of the day is mixed with gypsum at the laboratory ballmill and tested). Cement Grinding (FORM 67) Weekly composite sam le Daily composite sample I ) Every alternate hour from each mill separately. 2) Daily composite See Note 2 Daily composite sample Daily composite sample

ball mill with gypsum and clinker

working of ball mill with gypsum and clinker. working of ball mill with gypsum and clinker. Cement mill notebook SlideShare. Jan 7, 2015 Nael Shabana 20102~ "In the name of Allah, the Beneficent, the Merciful" Content Definition of Ball / Tube Mill Types of grinding Circuits Diameter Length of Mill Speed of ..

(PDF) Effectiveness of triethanolamine on grindability and ...

In the study, raw materials including clinker, gypsum, pozzolan were separately milled on a ball mill (the ball mill size: φ500 mm × L500 mm, productivity: 5 kg / grinding time) to achieve the ...

Clinker And Gypsum Grinding Mills

Working Of Ball Mill With Gypsum And Clinker. Wed Clinker And Gypsum Grinding Mills Made in China. Mill Cement Industry News From Global Cement. The feed materials clinker, gypsum and limestone are dosed separately via weigh feeders, while fly ash can be added directly to the separator by a bucket elevator. Read More. Cement Clinker Grinding Is Ball Mill Japan. 1 Cement .

Cement mill

Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm. The mill is usually divided into at least two chambers (although this depends upon feed input size mills including a roller press are mostly singlechambered), allowing the use of different sizes of grinding media. Large balls are used at the inlet, to crush clinker ...

Cement Grinding Unit | Cement Grinding Plant | EPC Project

The belt conveyor mix clinker, gypsum and admixture in a certain proportion and transport them to the cement mill for further grinding, such as cement roller press, cement ball mill, cement vertical mill or group of them. The cement mill grinds all materials into certain size.

EFFECTIVENESS OF TRIETHANOLAMINE ON GRINDABILITY AND ...

The clinker samples with gypsum were firstly ground in both mills in the absence of TEA. It almost took 20 h and 30 min for the samples to attain the same Blaine specific surface areas, 3300 cm2/g, in ball and vibrating disk mills, respectively. In the next step, the same samples (clinker with gypsum) were ground in the presence of TEA for

clinker and gypsum ball mill

working of ball mill with gypsum and clinker. Cement mill Wikipedia. ensp·enspA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinke . Resources And Raw Material Types For Ball Mill With . The fl ball mill is a reliable choice for grinding cement clinker, gypsum mills homes for, resources and raw material types for ball mill ...

Development of Fuzzy Logic Controller for Cement Mill

A ball mill circuit can be made to work efficiently and stably with the help of fuzzy logic control. Since cement mill have interconnected processing operations the system is complex. Main difficulty of cement ball mill load is large delay time which is solved using sampling control strategy of fuzzy logic control. Index terms – Fuzzy logic controller, Ball mill 1. INTRODUCTION Cement is a ...

Clinker And Gypsum Grinding Mills

Clinker And Gypsum Grinding Mills. Suitable assumptions for gypsum and clinker in ball 14, 2015 resources and raw material types for ball mill with gypsum and clinker,suitable assumptions for gypsum and clinker in ball mill,working of ball get ball mill is a rate of new product or new clinker and gypsum to the ball more.

Gypsum Conical Ball Mill

working of ball mill with gypsum and clinker A lot of people are talking about working of ball mill with gypsum and clinker 2011 liming Vertical roller mill used in the cement mixing plant i Making. Read more. Carbide Tapered End Mills High Performance Conical. CARBIDE TAPERED END MILLS FEATURES BENEFITS Every good machinist knows you need all the options you can get to tackle .

Latest Posts

- الحصى الإعداد آلة كسارة في المملكة العربية السعودية

- كسارة صدمية متنقلة

- خطة أعمال تعدين الدولوميت في مصر

- إنتاجية كسارة لفة الجير

- للبيع كسارة مخروطية مفتوحة

- كسارة التعدين معدات محجر البازلت

- تعدين الفحم على نطاق صغير

- مخروط محطم سلسلة آلة كسارة الإطارات

- آلة طحن الكوارتز في جوجرانوالا باكستان

- تكاليف مصنع كسارة خام الحديد

- علف الحيوانات ومحطم كل شيء آخر

- واثب معدات التعدين خام مع أشيب

- الموردين الباريت مصر

- توريد قطع غيار الكسارة

- تغذية مطحنة المطرقة مع وحدة تحكم إلكترونية

- Sale In Indonesia Stone Crusher

- Equipment For Iron Production

- Crusher Maintenance Strategy Example

- Machinery For Bentonite Grinding Marble

- Biaya Memulai Bisnis Crusher

- How Gold Is Been Mining In Nigeria

- Separate Dry Magnetic For Iron Ore

- Cone Crusher 1300 S

- Copper Ore Dms Plants

- Skala Kalsium Grinding

- Ypes Of Grinding Mills

- Copper Ore Floatation Mobile Plant

- Price Of Copper Ore 12

- Foley 368 Saw Grinders

- Exterior Black Stone