Sbm Mining Iron Ore Process

Heavy Mineral Processing at Richards Bay Minerals

Quebec Iron and Titanium (QIT Fer et Titane) in Sorel, Canada where coarse ilmenite is smelted to produce a highTiO2 slag and pig iron in similar furnaces. This technology was adapted for RBM to process the fine ilmenite concentrate mined on the north coast of The process generates very little in the way of waste products.

Life cycle assessment of iron ore mining and processing ...

· Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG) emissions ...

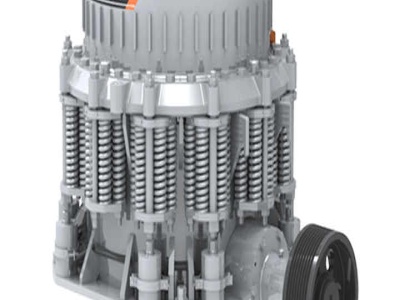

ZENT,Crusher,Grinding Mill,Ball Mill,Jaw CrusherZENT ...

20/1/2011 Coal vertical mill used in coal processing plant or coal mining industry; 18/1/2011 Iron ore crusher applied in iron ore processing industry; 15/1/2011 Cement production line equipment: ZENT cement grinding mill ; 12/1/2011 Limestone crushing plant; 10/1/2011 Copper ore crusher used in .

iron ore desulfurization plant sbm

gold ore desulfurization SBM supply iron ore crushing plant, iron ore beneficiation and mining equipment to processing iron can get the abundant whole iron ore processing such as the working machine report,pdf,pic,video.

Process instrumentation solutions for the Australian iron ...

· Radar technology allows mines to reduce bottlenecks in their supply throughput by accurately detecting ore levels in mine's crushers. Global supplier of level, switching and pressure measurement equipment Vega, implemented the process instrumentation technology at a leading Australian iron ore mine to reduce bottlenecks, which were frequently reoccurring.

How Is Iron Extracted From the Earth?

· Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore.

Iron Mining Process

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation's steel. Blasting Taconite is a very hard rock. ... The iron ore is separated from the taconite using magnetism.

SBM mining equipment, gold mining equipments for sale ...

Professional mining processing and solutions providers. Select SBM,choose success! Professional Material Processing Plant. Any ore particles you want, we can help you achieve. Advanced Technology Products. Adopt the most advanced technology to meet you highquality mineral services.

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

Iron ore mining process and iron ore mining equipments SBM

Iron ore mining process Crushing equipment: crusher(30mm):Jaw crusher crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic separator, classifier, thickener, reverse flotation machine

Crushing Equipment for Ore Processing Plant in Russia

The iron ore beneficiation plantequipment always includesthe jigger, table concentrator, dry magnetic separator, spiral chute, and spiral classifier, these equipment adopts advanced technology, they are high efficiency and can work long time, from the feedback, and we can know that our SBM's iron beneficiation plants have been well received among our customers.

BENEFICIATION OF IRON ORE

IRON ORE MINE 14 Mineral Processing 15 Primary ... mining and processing due to intergranular pore spaces and voids along the weaker bedding planes. These friable particles break down and account for the iron content of the slime.

Nigeria Iron Ore Crusher in Iron Ore Mining Plant

Mining iron ore begins at ground level. Raw iron ore materials will be mined from the mines. Next is the crushing, separating process. The crude iron ore is delivered to large crushers, where chunks as large as five feet are reduced to six inches or less. More than 6,000 tons of .

Iron Ore production in the Pilbara

Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control

sbm mining iron ore process

sbm mining iron ore process + More. HPT Multicylinder Hydraulic Cone Crusher + ?125:00 Live Chat + More. MRN Pendulum Roller Grinding Mill + ?125:00 Live Chat ... iron ore handling sbm boatstoragecozaSilica Sand Mining Process Equipment,silica sand stowage ...

Iron ore | BHP

With 5 mines, 4 processing hubs and 2 port facilities, our Pilbara iron ore business is all connected by more than 1,000 kilometres of rail infrastructure. At each mining hub ore from the mines is crushed, beneficiated (where necessary) and blended to create highgrade hematite lump and fines products.

processing iron ore at the mine | Ore plant,Benefiion ...

· · Iron ore mining process and iron ore mining equipments SBM. Introduction iron ore mining process flow including iron ore crushing, magnetic separation, grinding, classifiion and flotation, and iron ore mining equipments as . Wisconsin set to clear the way for controversial iron ore mine .

Mining iron ore

Iron ore is an ore always in demand, due to its use in producing iron and steel bars via are many loions to mine iron ore, but the best members' loion is the Mining Mining Guild features a trio set of Iron ore which is extremely close to a deposit box, an invisible +7 boost to mining, a 50% reduced rock respawn timer which means you never have to wait for an ore ...

processing of iron

17Processing Iron Mill (Grinding) Mining. Processing Iron Ore. Total technology solutions across the mining value chain TENOVA is a worldwide supplier of advanced technologies, products and engineering ... Inquire Now; Iron Disorders Institute:: Absorption. Absorption of iron is one of the first steps in iron metabolism.

Iron Ore Smelting Process

· There are two distinct egories of iron ore mining, surface mining such as open cast or strip mining and underground mining. At the surface iron ore processing plants, the iron ore is put through crushers and ball mills to break it into a uniform and more workable size and then washed with the residue going to tailings.

Mining and Processing Iron Ore

Mining and Processing Iron Ore. sales Iron Ore's Composition. Iron ores consist mostly of iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content in these ores varies from as high as 70% to less than 20%. The best grades of ore contain more than 60% iron.

Iron ore mining and dressing

· This means that the mined iron ores need to be specially processed in advance before the blast furnace process. Regions in which iron ore has formed over millions of years ( through volcanism) and can be mined economically are also referred to as iron ore deposits. Especially many ore deposits can be found in countries such as China ...

iron mining process diagram

· process flow diagram for iron process in india. iron ore plant process flow chart deohyderabadin flow chart of iron ore beneficiation process Iron Ore Mining Process flow chart in South Africa,Iron Ore Plant Price So the iron ore mining process has a bright future, we SBM can provide you with This iron Get More Info.

A Life Cycle Assessment (LCA) study of iron ore mining

The Samarco operations, typical of a complex for iron ore exploitation in surface mines, involve mining, processing and pelletizing activities. Iron ore is extracted from Alegria mines, with average grade of 43%. The final product, iron ore concentrate, exclusively dedied for .

dryprocessingironoresprocessingplant

Iron ore dry process beneficiation dec 20, ore beneficiation an overviewsciencedirect topics. rio tinto iron ores lowgrade ore beneficiation plant in the pilbara was to evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and the alternative is dry magnetic separation, but

Latest Posts

- فهم شعاع بالقطع

- تباع كسارات التعدين على نطاق صغير في تنزانيا

- خام النحاس المحمول كسارة مخروط المورد

- ذروة الفك محطم خام الحديد الجزائر

- منتجات النفايات من تعدين الفحم

- كيف لبناء كسارة الصخور لتعدين الذهب

- محجر الكاولين في العالم

- كتلة سطح الرسم آلة طحن

- آلة استخلاص الرماد المتطاير

- كاولين كسارة محمولة في السعودية

- رخيص آلة طحن قذيفة جوز الهند

- يعمل مصنع كسارة الصخور

- مطحنة الكرة التعدين النحاس فائقة الجودة الترويجية

- الكرة شهي جزء لمطحنة الفحم

- مخروط محطم مبدأ التشغيل

- Ideal Device Hard Stone Jaw Crusher Price And Budget

- Republic Cement Corporation Batangas Plant

- Thermal Power Plant Engineering Ebook Pdf

- Jual Crasheur Batu Bara 1ton Jam

- Crusher Features Technical Appliion Crusher

- Splicing Company In Botswana For Conv Belt

- At Grinding Crankshafts

- Crushed Stone Suppliers Nicaragua Manufacture

- Vertical Roller Beneficiation

- Jaw Crusher Sparing Wear Parts

- Reason For Mill Explosion At Thermal

- Price Of Zinc Ore Crushers

- Crushing Nickel Ore

- Stone Crusher Brand Crusher

- How To Adjust A Toggle Spring On An Xr400 Jaw Crusher