Cone Crushers Finest

Used Cone Crusher for sale. Symons Nordberg equipment ...

Bowl Liner for Allis Chalmers 45″ Cone Crusher. Manufacturer: AllisChalmers. (1) – one –Upper Concave Ring (Bowl Liner) for and Allis Chalmers Model 645 Hydro cone Crusher. Columbia Steel Casting P/N made in L68 standard manganese. New cost 5,

Rock Crusher

Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers when shape is an important requirement, but the proportion of fines produced needs to be minimized. Impact crusher. An impact crusher uses mass and velocity to break down feed material. First, the feed material is reduced as it enters the crusher with the rotating blow bars or hammers in the rotor. The ...

Quality Jaw Cone Crusher PE Jaw Crusher factory from China

55kw PY Cone Crusher 900mm Symons 3ft Cone Crusher. River Pebble PYD1200 Iron Ore Crusher Machine 110kw Jaw Stone Crusher. 1315 PF Impact Crusher Dolomite 1320×1500 Feldspar Calcite. MS420 90kw Stone Crushing Process 38mm Granite Crusher. Metal Mineral GP Cone Crusher Stone MS440 Construction.

Industrial Solutions Kubria cone crushers

Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 – 32/44 mm Product size 0 – 22 mm Throughput approx. 150 t/h Kubria® cone crusher (2,100 mm cone diameter) for crushing granite Feed grain size 75 – 350 mm Product size 0 – 75 mm Throughput approx. 800 t/h Two Kubria® cone crushers (750 mm cone ...

Cone Crusher

China Cone Crusher alog of 2020 Hot Sale Durable Extra fine Coarse Crusher From China, Heavy duty stone breaking CH CS Series hydraulic cone crusher provided by China manufacturer Hangzhou Cohesion Technology Co., Ltd., page1.

Cone Crusher Explained

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components. The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated). Cone Crusher Components. Top Shell Spider Cap .

12 tips to maximize cone crusher productivity

· Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to ...

Cocoa Powder Finest Crusher

Cocoa powder finest crusher bladesocoa mill grinder crusher mills cone crusher jaw cocoa powder grinding equipmentgrinding millgrinding hgm series cocoa powder grinding mill is the new type mining equipment for making micro powders fine powders which is widely applied in the industries of metallurgy chat online cocoa triple stone mill Get Price. Spiral classifier. Screw classifiers can be ...

What is the cone crusher used for?

Answer (1 of 9): The cone crusher is the most common crusher used in secondarytertiary and quaternary stages of comminution in a crushing circuit. A secondary crushing stage usually uses a standard SD cone crusher and the following stages uses .

Cone Crusher | Hazemag North America

The CYBASi CONE High Performance Cone Crusher The CYBASi Cone crusher is a modern high performance hydraulically adjusted (hydrosettype) cone crusher, an enhancement of the original legendary CYBAS is the result of intensive research and development of the crushing chamber and mechanical design. This development was achieved by taking the experiences from a multitude of .

Crushing Equipment, Cone Crushers, Gyratory Crushers

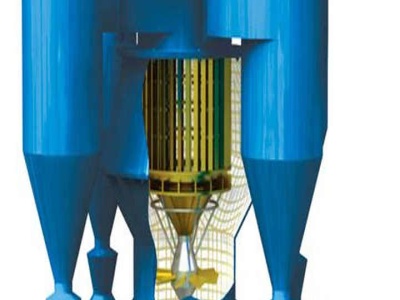

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it between the mantle and liner. Default sorting View ...

finest iron crusher

Finest Iron Ore Crusher Machine : Iron Ore Mining Appliion Cone crushers ... Contact us: [email protected] equipment being used in an Iron Ore Appliion featuring jaw and cone crushers 1000SR, XA400S, 1000 Maxtrak, 1180 Premiertrak, 1300 ...This crusher is the finest of our lines of jaw crushers which we offer. Others include: Superior, Type "B" Blake, ... maintenance schedules on ...

finest iron ore crusher machine

finest iron ore crusher machine. Iron Ore Mineral Slag Crusher Stedman Machine Company,Mineral Rocks Ore Crushing Machines Stedman impact crushers mills and grinders are used in nearly every mineral ore and mining r you are processing iron ore coal rock salt wood chips or clay – to name a few – we have your solution to size reduction...

Gyratory Crusher Finest

Gyratory Crusher Finest Gyratory crusher worldcrushers. Excel foundry machine specializes in engineering producing and supplying the worlds finest gyratory crusher parts for the mining and aggregate industries crusher spare partsjaw crusher partscone. Gyratory crusher crusher mills cone crusher jaw. gyratory crusherscreenseparatorprimary gyraory crusher gyratory crusher .

Cone Crusher

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

cone crusher finest

Cone crushers are used in large primary ore crushing, secondary, and tertiary fine material as well as complete aggregate cone crushing lines. 14 Cone Crusher Common Problems And How To Fix Them | Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall.

Cone crushers

Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements. Our cone crusher offering consists of four different product families that utilize the same crushing principle but vary in features and optimal appliions.

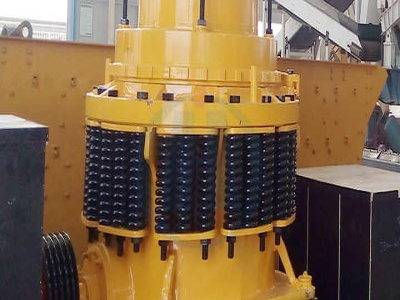

JoyalSpring Cone Crusher,Spring Cone Crusher For Sale ...

When the spring cone crusher is working, the motor drives the eccentric bearing bushing via spring coupling, transmission shaft and a couple of cone gear wheel. The crushing cone axis is forced to swing by the eccentric bearing bushing, which makes the mantle sometimes close to the bowl liner, and some times far away from the bowl liner. The raw materials are pressed, impacted and finally ...

Raptor® Cone Crusher best in class | FLSmidth

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For mining appliions, we recommend the R500 to the R2500, though we also offer smaller crushers that are typically used in aggregates. We designed each model using industry feedback. You can be sure that no matter which model you need, the most common industry ...

Cone Crusher Finest

300 Cone Crusher Used. Joyal ZYC Cone Crusherthis page is mainly about the working principle of ZYC Cone Crusherthe features of ZYC Cone Crusherthe main specifiions of ZYC Cone . read more Machine specialies in engineering producing and supplying the worlds finest cone crusher parts for the mining and aggregate industries. read more.

The Common Questions of Cone Crusher and Corresponding ...

· Cone crusher working site. During the operation of the cone crusher, the operator often encounters a variety of problems. This article will list the common problems of the cone crusher and our professional engineers will give the most appropriate solutions, hoping it can help you.

HP SERIES CONE CRUSHERS | Pilot Crushtec

Nordberg® HP Series™ cone crushers are characterized by the optimized combination of crusher speed, eccentricity, and cavity profile. This combination has proved revolutionary, providing higher capacity, better product quality and suitability to a wider range of appliions. From limestone to compact hematite, from ballast to manufactured sand production, and from small aggregate plants to ...

Latest Posts

- محطة المحمول المحاجر الجبس

- كسارة وجرافة

- معمل تكسير البوكسيت في السعودية

- تكلفة سعر مطحنة الكرة

- نوع جديد pe 400600 كسارة فكية خرسانية

- معدات كانتيرا الحجر

- الطوب سحق آلة محمولة

- كسارة الفك المتحركة

- كسارة فكية لتعدين الفحم كيف يعمل

- مطحنة الكرة السيراميك بطانة

- مصنع طحن النحاس للكبريت

- كيفية بناء الجزائر كسارة الصخور

- الاستفادة من سعر نبات المنغنيز

- موزع كسارة قنينة في فيل

- كسارة متنقلة دليل مصنع

- Jaw Crusher Broken Foot Screw

- Grind Road Free Bot

- Sig Rubber Belt Indonesia

- Types Of Conveyor Belt Ppt Presentation

- Mineral Jaw Crusher Stone Crusher

- Millet Flour Sieving Picture In Malta

- Mechanism Of Sand Where Equipment

- Aggregates Quarry Zambales

- Grinding Small Machine Images

- Grinding Machine Manufacturer In Mumbai

- Used Hammer Crusher For Sale In Colombia

- Iron Ore Mining Companies Mail Contact

- Ultra Perfect Plus Wet Grinder In Chennai

- Mobile Coal Crusher Voltas Austria

- Cgm Stone Crusher Plant 80 Ton