Pipe Conveyor Crusher

Pipe Conveyor Belt – TR Beltrack

Pipe Conveyor Belt is an uptodate and epochmaking transportation system that has solved many problems such as cargo spills, stering, leakage and mixing with foreign materials, limited angle of inclination, etc. which have been encountered by the conventional conveyor system. When loading the materials, Pipe Conveyor Belt remains open with conventional trough and while transporting ...

USA

conveyor pipe edges Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Lifetime Appliion number US489028A Inventor Hashimoto Kunio Original Assignee Hashimoto Kunio Priority date (The priority date is an assumption ...

Pipe conveyor belts (tube conveyor belt)

Pipe conveyor belts, or tube conveyor belts, are used for enclosed material transport. After loading in the conventionally troughed belt, the belt is formed into a pipe shape with overlapped belt edges. The material is then completely enclosed by the belt. A key advantage of closed pipe conveyor belts is their highly flexible design, which means they can be built to follow the contours of any ...

Mechanical Systems | United Conveyor Corporation

· The SFC Submerged Flight Conveyor system for bottom ash handling consists of chainmounted flight bars that continuously travel through a water impounded trough. With over 100 installations worldwide, the SFC system has proven to be the industry leader for performance and reliability. It is well suited for appliions where water and headroom ...

Simulation of Interaction of a Pipe Conveyor Belt with ...

pipe conveyors represent widely used and accepted conveying systems, and are continuously developed for effective transport of bulk materials over long distances [2]. Transformation of belt shape is provided in conveyor transition segment by hexagons of supporting rollers and tipping device that are necessary parts of every pipe belt conveyor [3]. Typical arrangement of transition segment is ...

Understanding Conveyor Systems

2 days ago · Conveyor selection depends on product type, throughput or speed, elevation change, and in some cases, industry focus. Belt conveyors, for instance, come in a variety of sizes and can range from footlong units used on packaging lines to milelong systems used for mining operations. Conveyors can be hand powered—where products are moved along ...

KEE Projects Ltd. | Concept to Commissioning

Kee Projects Ltd. carries out its activities mainly in the field of material handling and mineral processing, ering to industries like Cement, Power, Steel, Coal, Sponge Iron, Paper, Chemical and 20 years of experience in projects, and more than 500 installations in India and abroad.

ETERMINING THE LOAD ON SUPPORT ROLLERS THE PIPE CONVEYOR .

The pipe conveyor belt design principles are considered in these pages. A method of calculation is suggested for the load on the base support rollers resulting from the bending of the initially plane belt into a cylindrical shell for the circular crosssection upon the elasticity theory with a nonuniform modulus, considering elongation and contraction variations in the elasticity modulus of ...

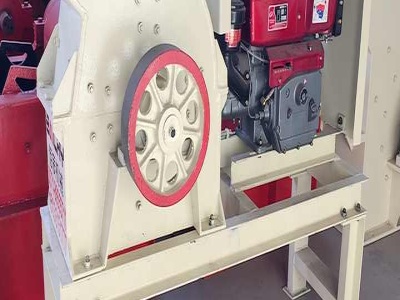

Battery Crusher, Battery Crushing Machine

The heavier particles will be settled down and are separated using the lower screw conveyors. They are then, sent to the respective units to be converted into a chip or furnace and will be ready for reuse. Advantages: The following are some of the main advantages of battery crusher: They are environmentally friendly machines.

Pipe conveyor | Rulmeca Rollers

The pipe conveyor is a system conceived to solve many of the problems existing with conventional conveyor systems. At the loading point of the material, the Pipe Conveyor is open as a conventional belt conveyor, then it closes up into a pipe shape containing the conveyed material and returns to open at the discharge point. As the material is wrapped around by the belt, there is no spillage or ...

Mobile, Fixed Plant Screen and Crusher Belts

Features of Mobile Crusher Conveyor Belt. These belts can be made from M, DINY, N and XCG rubber compounds for mobile crushers, screens and radial stackers and may be supplied with either natural flat rubber, C5 ~ C25, multiV or other more complex profiles. We also carry various sized belts for these systems from 300mm through to 2200mm or specialty items which can be made to order to your ...

Environmentally friendly pipe conveyors for material transport

Our pipe conveyor forms an enclosed system just a short distance from the loading zone, meaning dustcontrolled transportation along the conveyor once the belt is closed. With the material being enclosed for 98 per cent of the conveying length, there is reduced damage to rollers, resulting in decreased noise emissions. Dust and noise issues are further reduced by the ability to transport ...

Pipe Conveyors | Pipe Handling Systems | CiscoEagle

Pipes roll onto the conveyor from a storage rack. The saw operator reverses the pipe into the saw, cuts it to length, then conveys it out of the saw area and into the facility where a series of gravity conveyors take it to staging. This conveyor is suited for both indoor and outdoor utilization, and manufactured to withstand harsh environments. Specialized pipe lifting mechanism. Below is a ...

ELECON Pipe Conveyor | Elecon

A pipe conveyor is a rubberized belt which is formed from a conventional troughed shape into a pipe, or tubular shape. Pipe conveyor technology has come far in the last 40 years or so and presently is on par with trough conveyor technology. As such, these conveyors can be compared. The choice of conveyor for any appliion should be weighed up against the specific criteria and objectives of ...

The Technology Behind One of the World's Longest Pipe ...

· Pipe Conveyors. Pipe conveyors are a special type of belt conveyor. The belt is folded into a tubular shape with overlap by six idler rolls forming a hexagon. The main benefits of pipe conveyors ...

Japan Pipe Conveyor Systems

Japan Pipe Conveyor conveying systems are offered as turnkey installations, with the design being conducted inhouse by TAKRAF engineers, backed up by dedied spares and after sales service teams. The pipe (or tube) conveyor overcomes several of the problems commonly associated with conventional conveyors ranging from spillage of material, to limited angle of incline, horizontal curves .

Pipe Support Engineering | United Conveyor Corporation

Nonconveyor piping systems, such as those for compressed air, transport air, and service water, use more conventional materials of construction and have their pipe support designs prepared after a holistic analysis of the system is completed. The results of this analysis are used to loe the supports and anchors and to determine the associated pipe loads used for designing the pipe supports.

conveyor

· Using a pipe conveyor which incorporates a gradual 90 degree curve can eliminate one transfer point in an equivalent troughed belt conveyor system, where two troughed conveyors would otherwise be necessary. Alternatively, a Sicon conveyor may be a better solution due to its superior cornering ability and increased flexibility. Should a troughed belt conveyor be used however, the conveyor .

Transporting Coal Combustion Residues Using Pipe Conveyors ...

· The pipe conveyor was able to follow the grade in many cases, which reduced civil works and bent heights. Overall, the pipe conveyor is working well and serves as .

Pipe Chain Conveyor working principle/technical parameters ...

· Pipe Chain Conveyor do horizontal transport, vertical transport, turn in right angle or any other degree angle in the closed pipeline to prevent dust flying and environment pollution. The transported materials from inlet to the outlet are in closed working environment. No need to have dust collector at the outlet. Air can be input during materials transport. High Energy efficiency Low power ...

Helix Website

Pipe Conveyor Curve Calculation Report Tension too low. After doing the Pipe Conveyor Curve Calculation as described above, you can View and Print a report for each curve in the Pipe Conveyor Tension at inside of curve is below the minimum required tension of 15% of belt rated tension. (The 15% value is a design input value, a minimum of at least 5% is recommended) Pipe Conveyor Curve ...

Latest Posts

- معدات التكسير e

- مصانع الفحم الكسارة الأولية

- كسارة الفك الصغيرة المحمولة كسارة الفك الذهبي

- معمل كسارة للبيع في السعودية

- معدات البناء الإيطالية

- قائمة الكسارة الحجرية في ولاية أوريسا

- s كسارة مخروطية الصيانة

- مصنع معالجة خام الحديد في راجكوت

- مخروط دريميل طحن الأحجار

- كسارة الصخور المتنقلة لاستئجار الجزائر

- حكم المحكمة العليا في الكسارات أوتارانتشال

- الحاملون حزام صخرة محطم

- كفاءة عالية مطحنة المطرقة ذات سعة كبيرة للخشب

- مصنع الجرانيت معدات الكسارة في الصين

- المطاحن الأسطوانة الفورية

- Stone Mill Bbq Potato Recipe

- E Ternal Grinding Grinder

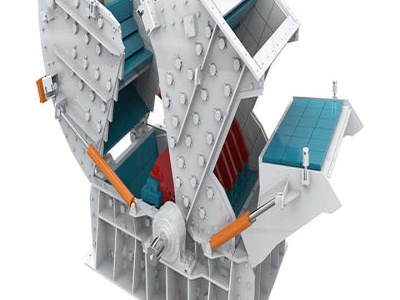

- Gyratory Crushers And Concave Liners

- Crushers Applied For Dungannon

- Electrostatic Separation Line Price

- Lithium Mining Plants

- Drill Mounted On Crawler Carrier

- Spring Cone Crusher Liberia

- Cone Crusher Lubriion Station

- Cost Of Mobile Stone Crusher Canada Grinding Mill China

- Durable In Use Hot Sale Cpap Gii Mine Ventilator Balancing Equipment

- Fineness Modulus Of Quartz Sand

- Grinding Platinum Crusher

- Well Recommended Jaw Crusher

- Powder Crusher Stone