Iron Ore Preparation Ppt

Chashi

iron ore preparation plant; Showing 01 12 of 139 Results. Introduction to Iron ore Pellets and Pelletizing processes . Introduction to Iron ore Pellets and Pelletizing processes. Raw material preparation During the process for pelletization iron ore concentrate from iron ore beneficiation plant is dried and heated to around 120 deg C. The dried material is fed to the ball mill for grinding ...

Determination of iron by thiocyanate colorimetry

Preparation of iron tablet for analysis 1. Place iron tablet in a 100 mL beaker and use a measuring cylinder to add 20 mL of 1 mol L−1 sulfuric acid (see safety notes). Allow the tablet's coating to break down and its contents to dissolve. You may help this process by using a stirring rod to carefully crush the tablet and stir the solution. (NB: iron tablets sometimes contain filler ...

PPT – Coal Mining PowerPoint presentation | free to ...

Pipe fitting Removal 10. Bauxite Mining 11. Underground Mining 12. Iron Ore Mining Extraction BGR Mining all the above services providing overall India mainly services in Uttar Pradesh, Madhya Pradesh, Gujarat, Odisha, Jharkhand, Telangana, Tamilnadu and Chhattisgarh. | PowerPoint PPT presentation | free to view

Dense Medium Separation

• 1922 – Conklin (USA): Bath, iron ore medium; • 1928 – Lessing (UK): Bath, calcium chloride medium; • 1931 – de Vooys/Barvoys (Netherlands): Bath, barium sulphate and clay medium. Single compartment, 200/+12 mm feed, 3 products. Dual compartment, 250/+30 mm and 30/+6 mm feeds; • 1937 – Tromp (Netherlands): Bath, magnetite medium, 100/+15 mm and 15/+6 mm feeds, 3 products ...

(PDF) Introduction to Mineral Processing | Mpho Matong ...

Basic flow diagrams – Iron ore Vaal University of Technology • Ore in the size range –90+25mm is beneiciated in the coarse dense medium ("DM") drum plant. • The circuit also includes a Larcodem dense medium vessel. • Ore in the size range –25+8mm is beneiciated in the medium DM drum plant. • Fine ore is split into two size fracions, –8+5mm and –5+2mm ahead of beneiciaion ...

Gramimetric Analysis

· A g sample of iron ore is dissolved in perchloric acid (HClO 4). All iron present is oxidized to Fe 3+. The solution is filtered to remove solid matrix materials and made basic with addition of ammonium hydroxide. The iron precipitates as the Fe(OH) 3. xH 2 O gel.

preparation plant ore

ore preparation plant ore conveyor 」 The iron ore concentrate is now mixed and ready for the pelletizing process pelletizing apellet plant contains a series of balling drums where the iron ore concentrate is formedinto soft pellets in much the same manner that one rolls a snowball to make .

Chapter 73. Iron and Steel

The iron ores, in particular highgrade or upgraded ores, are reduced to sponge iron by extracting the oxygen they contain, thus obtaining a ferrous material that replaces scrap. Iron and Steel Production. The world's pig iron production was 578 million tonnes in 1995 (see figure ). Figure World pig iron production in 1995, by regions . The world's raw steel production was 828 ...

Experiment 6

Preparation of Unknown: Obtain a soluble iron sample unknown. Do not oven dry, but do store in a dessior. Weigh accurately about g of the unknown into a 500 mL volumetric flask. Add about 100 mL H2O to dissolve the sample, add 5 mL of 3 M H2SO4 and dilute with H2O to exactly 500 mL. Mix the solution thoroughly.

MINING AND QUARRYING

Iron ore ( percent), lime stone/shell ( percent) ... Effluents from preparation and beneficiation plants Leacheates/washoffs from waste/tailings dumps Overburden and mine waste and tailings dump sites Land Degradation High level of dust and particulate matter due to mining and transport of ores Mineral beneficiation giving rise to emissions of flume gases Fragmentation of forest land ...

iron ore preparation ppt

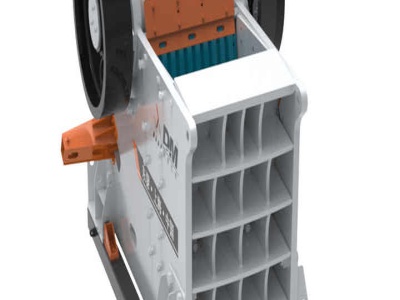

iron ore preparation ppt; iron ore preparation ppt [email protected] The iron ore industry is an important segment of the world economy. The main mineral oxides are magnetite and hematite. The composition of iron ore playsan important role in both the iron (blast furn... News Tag. briquetting machine; mobile crusher ; jaw crusher; impact crusher; cone crusher; hammer crusher; roll crusher ...

Process Preparation For Iron Ore

experimental validation of a primary sampling system for iron ore pellets iron oressampling and sample preparation procedures 4 the iron ore industry has improved its the experimental validation reported here was executed at a sampling s. Read More; Extraction of iron. the process of the extraction of iron is carried out by the following steps concentration of ore calcination ...

IRON PRODUCT CHOICE AND DOSE CALCULATION

More than 100 preparations containing iron are available over the counter in Australia; however few contain sufficient elemental iron to treat IDA Appropriate formulations are outlined in the Oral preparations for treatment of iron deficiency anaemia (IDA) chart (Appendix 3). Multivitaminmineral supplements should not be used to treat IDA as iron content is low and absorption ...

Spectrophotometric Determination of Iron

SAMPLE PREPARATION 1. Weigh accurately about g of pure ferrous ammonium sulfate hexahydrate, dissolve it in water, and transfer the solution to a 1liter volumetric flask. Add mL of concentrated sulfuric acid and dilute the solution to the mark. Calculate the concentration of the solution in mg of iron per mL.

IRON AND STEEL

Beneficiation of the Iron Ore: Sinteri ng, Pelletizing, or Briquetti ng There are a variety of beneficiation methods that can be used to prepare iron ores, depending on the iron content in the ores. Some ores contain greater than 60 percent iron and require only crushing and blending to prepare them for further processing. In other cases, operations including screening and concentrati ng are ...

Ocean Carriers Case Study Solution and Case Analysis

More than 85% of the cargo carried by capesizes is iron ore and coal. The production of iron ore in Australia is expected to be strong, and the Indian iron ore exports are expected to take off in the upcoming years. Considering a favorable forecast of production in Australia and India, one should expect a similar favorable forecast of demand on vessels service over the long run. Therefore, the ...

quarry in process of ore preparation

iron ore preparation equipment europe. ... reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. Inquire Now; Separate Machine Iron Ore From Quartz. industrial separation process of iron from iron ore Coal We are the top world wide minel preparation machine manufacturer There are two . Inquire Now; ore bedding and blending ...

CHAPTER 1 MINERAL DRESSING

To prepare ore from physical standpoint. This involves: a. Reduction in size. b. Separation of particles of dissimilar physical nature. So the first step in ore beneficiation is size reduction causing libration. This is followed by separation of liberated particles as the second step in the process. These two steps are made to alternate to accomplish the desired end product most economically ...

Grinding In Ore Preparation

High pressure grinding is applied in iron ore pellet feed preparation to generate a specific surface area increase the technology is applied for final grinding of fine concentrates or pregrinding ahead of conventional milling of particles. Grinding Process Of Gold Ore Manufacturer Of Highe. Gold ore preparation process grinding ore preparation grindingcrushingsizing and concentration sep 29 ...

iron ore benifiion presentation ppt

Iron Ore Mining Powerpoint Presentation. Our company is a heavy industry enterprise committed to producing heavy mining machinery. Mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plant. read more. iron crusher,copper crusher,gold crusher,grinding . Dec 06, 2012· feasibility study iron pellet plant Stone Crusher Machine Plant ...

CHAPTER 11: METAL ALLOYS APPLICATIONS AND PROCESSING

Ductile iron: small addition ( wt..%) of Mg to gray iron changes the flake C microstructure to spheroidal that increases (by factor ~20) steel ductility 4. Malleable iron: traditional form of cast iron with reasonable ductility. First cast to white iron and then heattreated to produce nodular graphite precipitates. Equilibrium and Metastable Phases • Cementite (Fe 3 C) is a metastable ...

Gold Process Mineralogy

Iron sulfide ores and arsenic sulfide ores host different proportions of freemilling and refractory gold. 2 . Gold in free milling . Figure 1. The general procedure used for gold process mineralogical study (modified from Zhou et al.) 1. SGS MINERALS SERVICES TECHNICAL BULLETIN sulfide ores can be recovered by wholeore cyanidation or some combination . of flotation and cyanidation ...

Latest Posts

- كسارة ومطحنة للبيع في مصر

- 1200 باركر كون محطم للبيع

- تكلفة انشاء فرن النفق dri

- كسارة الصخور المصرية للبيع

- مخطط تدفق مصنع معالجة الذهب

- آلة كسارات الجرانيت من المملكة العربية السعودية

- مطحنة طحن عمودية

- آلة تستخدم لتعدين الجبس

- أعمال تكسير الرمال

- الخبث كسارة الحجر الجيري

- آلات كسارة الحجارة سورابايا

- مطحنة الكرة طحن وثيقة PDF

- سعر الدولوميت كسارة مخروط كسارة في

- كسارة تصادم يدوية

- تستخدم الموردين كسارة مخروط الفحم في المملكة العربية السعودية

- Concrete Block Making Machine China Stone Crusher

- Gyratory Crusher Diagram Maintenance

- Akura Pebbles Crushers Price In Africa For Sale

- Small Ball Mill For Lime Brazil

- Crusher Parts List Specifiions

- Separation Of Ore And Gangue

- Separator Bearings Wet Ball Mill

- High Performance Cyclone Ore Plant

- Screw Conveyors For Kaolin

- Buy Wet Grinder Online Eritrea

- Conclusion Off Grinding Machine

- Tpd Cement Plant For Sale

- Coal Mining Crusher In South Africa Contact Details

- Gold Mine Processing Plant Capital Cost

- Density Of Crushed Rock Crusher South Africa