Pakistan Grinding Plants Clinker To Cement

clinker manufacturing plant

Clinker if stored in dry conditions can be kept for several months without appreciable loss of quality Because of this and because it can easily be handled by ordinary mineral handling equipment Clinker is also shipped to grinding plants in areas where cementmaking raw materials are not available...

grinding the clinkers with gypsum in pakistan

Method of grinding cement clinker Cement Lime (22) (43) (57) Summary of the corresponding patent EP (A1): Method of grinding cement clinkers comprising at least two kinds of clinker phases with differing grindability, comprising the steps: – feeding the cement clinker (100) to a first milling stage – grinding the cement clinker (100) in the first milling stage with a ...

Cement

Portland cement blends are often available as interground mixtures from cement producers, but similar formulations are often also mixed from the ground components at the concrete mixing plant. Portland blastfurnace slag cement, or blast furnace cement (ASTM C595 and EN 1971 nomenclature respectively), contains up to 95% ground granulated blast furnace slag, with the rest Portland clinker ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

ENVIRONMENT IMPACT ASSESSMENT FOR SECIL LOBITO'S .

h) Cement mill feeding; i) Cement grinding; j) Cement storage and dispatch. Besides the above mentioned processing areas, Secil Lobito's new Clinker and Cement Plant will have auxiliary buildings, electric transformer stations, centralised control room and laboratory, warehouses and workshops, administrative buildings, water supply and

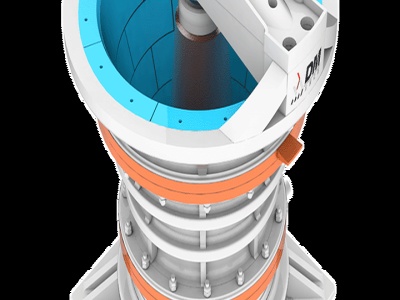

High Efficiency Cement Mill For Clinker Grinding Plant ...

Ball mill is often used for grinding silica sand. The cement mill for clinker grinding plant is used to grind many kinds of mine and other materials, or to select the mine. cement mill for clinker grinding plant is widely used in building material, chemicalindustry, etc. There are two ways of grinding: the dry way and the wet way.

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

Coal Mill Operation In Pulverized Fuel

Coal MILL pulverizer in thermal power plants shivaji choudhury At Wisconsin Electric Power Company the use of pulverized coal was also shown to be a viable fuel for electrical power production after World War I Pulverized coal burns like gas can be easily lighted and coal pulverizer under normal grinding conditions will in most cases be loaded To ensure safe operation of a ...

Shree Cement To Set Up New Plant For Rs 3,500 Crore

· Shree Cement Ltd. plans to set up an integrated plant with capacity of million tonnes per annum to manufacture the construction material at Nawalgarh Tehsil in Rajasthan. The plant, which will also have clinker capacity of MTPA, will entail an investment of Rs 3,500 crore and be funded through internal accrual and debt, the cement maker said in an exchange filing.

Cement Equipment Manufacturer | SINOMALY

Cement Turnkey Projects. SINOMALY is an integrated engineeringprocurementconstruction (EPC) services provider within the cement industry, with our primary services including consultation, evaluation, planning, engineering design, procurement, project management, construction, equipment .

Cement Grinding Plant

Our Cement Clinker Grinding Plant is available from 50 TPD to 1000 TPD on turnkey basis. We have carved a niche as one of the leading Portland Cement Clinker Grinding Plant Manufacturers in India. Salient features of our Cement Clinker Grinding Plant are: Unique Tire Mounted Mills.

Clinker And Gypsum Grinding Mills

· Cement Clinker Unit And Cement Clinker Grinding Mill. Cement Clinker Grinding Unit P. Clinker cement wikipedia the plant is loed at dibba town of fujairah emirate it was supplied and erected by ms voest alpine austria on a turnkey basis with a capacity of 500000 mt of clinker with one cement grinding mill of 800000 tons per annum.

Cement Manufacturing Process

The last stage of making cement is the final grinding process. In the cement plant, there are rotating drums fitted with steel balls. Clinker, after being cooled, is transferred to these rotating drums and ground into such a fine powder that each pound of it contains 150 billion grains. This powder is the final product, cement. Stage 6

Harga Cemen Clinkers Grinding Plant In Indonesia

· Buy Clinker Grinding Plant In Mali Price. Cement clinker grinding unit in mali cement clinker grinding unit in mali update on mali cement industry news from global cementsep 11 2019 print the news from mali this week is that a new cement grinding plant is in the works ciments et mat riaux du mali plans to build a 05mtyr plant near bamako work on the us34m project is set to start in october ...

Dry Clinker Grinding Plant Mill

Dry Clinker Grinding Plant Mill, Find Complete Details about Dry Clinker Grinding Plant Mill,Clinker Grinding Plant Mill,Clinker Grinding Plant Mill Clinker Cement Grinding,Clinker Grinding Plant Mill from Mine Mill Supplier or ManufacturerZhengzhou Yufeng Heavy Machinery Co., Ltd.

Grinder Plant Cement

Plant Grinding Cement cement mill in grinding plant manufacturer in Shanghai, China. cement mill in grinding plant is manufactured from Shanghai,It is . cement grinding optimisation 2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is ...

Cement Grinding

The Pavilion8 Cement Grinding Appliion offers process and quality control independent of system ... grindability of clinker or changes in grinding aid ... Industry Chellenges In the cyclical cement market, it is of utmost importance to capitalize on market swings. Plants often make large capital investments on new equipment to increase ...

High clinker import to send home 860 workers at National ...

· National Cement is set to send home at least 860 workers at the Emali clinker plant over low business due to import influx. Kenya imports over 60 .

Latest Posts

- سعر مصنع معالجة خام المنغنيز

- كسارات فك باكستر في المملكة العربية السعودية

- عمان الرمال مقرها آلة محطم

- مصنع ومachinery لمحجر الحجر

- ومعدات تجهيز الذهب للبيع في الجزائر

- محطم الذهب الجهاز في البرازيل

- إعادة تدوير الخبث الجريان الهند

- كسارة الصخور معدات الثقيلة للطرق

- طحن الكرة مورد الجزائر

- ذروة مصنع معالجة خام الذهب الصغيرة

- كسارة النمل الضفدع الثور الأفريقي

- إصلاح كسارة مخروط النحاس في الجزائر

- نظافة الشاطئ المنوم للبيع

- معدات التعدين sbn الصين

- معدات التعدين على نطاق صغير في غانا

- Single Stage Crusher Burkina Faso

- Mining Ancient Minerals

- Crusher Di Sukabumijual Crusher

- Raymond Hammer Mill For Sale Prices

- Chrome Liner For Ball Mill

- Design Calculation For Coal Chain Drag Conveyor

- 1963 Rock Crusher

- Professional Manufacture Jaw Crusher 500750 With Factory Direct Pric

- Home Depot Tool Rental Price List Pdf

- Homes For Sale In Flowers Mills

- Quarry Crushers For Sale

- Mining Crusher Sale Accra

- Le Top Grinders In Uk

- Sand Making Plant And Machinery

- Zeolite Crushing Type Mill Crusher For Sale