Vsma Dewatering Screen Sizing Formula

A Comprehensive Guide to Decanter Centrifuge Operation ...

Sludge Dewatering. Mechanical dewatering with a decanter centrifuge can result in a 95% reduction in volume and a concentration of between 15% to 35% dry solids, compared with 80% volume reduction and solids concentration of 3% to 7% with a sludge thickeningonly operation.

Vibrating Screen Types

Dewatering Screen. Dewatering screens have been designed to allow the drainage of slurry material water and to reduce the moisture rate of the material. These systems comprise a vibromotor pair, a vibromotor console, screening media and a screen body. The screen surface is slightly inclined (between 0° and 5°) to facilitate drainage and the working speed is between 1000–1500 RPM. The ...

Conveyor Horsepower Calculator

Superior's conveyor calculator provides the minimum horsepower required at the headshaft of a conveyor.

DEWATERING CONTROL OF GROUNDWATER

Groundwater can be controlled by means of one or more types of dewatering systems appropriate to the size and depth of the excavation, geological conditions, and characteristics of the soil. Construction sites are dewatered for the following purposes: 1 To provide suitable working surface of the bottom of the excavation. 2 To stabilize the banks of the excavation thus avoiding the hazards of ...

Dewatering Screws

Description. The screw press is equipped with cylindrical screen plates, mounted in casings. Each casing consists of 2 half scales which are bolted together. The screw auger starts cylindrical at the inlet side to become conical at the outlet side. Combined with a changing pitch of the screw blades, this causes increased pressure on the product.

Dewatering Calculations, Treatment and Supporting ...

Dewatering Calculations, Treatment and Supporting Documentation I. Purpose AECOM conducted the following activities to determine the best approach for management of water generated during the proposed Interim Remedial Measures (IRM) excavation work. x General review of treatment options and selection of methods to test, x Pumping and chemistry testing, and x Treatability tests completed by ...

Asphalt Mixing Plant: Vibrating Screen Guideline

will give you base data to do a mathematic vibrating screen sizing (standard formula) to determine the size of the vibrating screen needed in square feet to do the job. must cross check the BED DEPTH to decide if it meets the guidelines of VSMA. This will either leave the size the same or require you to UPSIZE the machine footage to meet the bed depth needs. In other words, we DO ...

(PDF) Technical Paper TJCI201 SCREEN CAPACITY ...

Most manufacturers use a modified version of the VSMA (Vibrating Screen Manufactures Association) formula to determine screen capacity. The twelve factors used in the formula below are based in large part on the VSMA charts and formula. Formula: A = B * S * D *V * H *T * K *Y * P * O * W * F "A", the calculated capacity per square foot of screen area in tons per hour. B = Basic capacity ...

Appendix N: Tailings and Rejects Management Plan

flotation feed sizing of mm. Caval Ridge Project – Environmental Impact Statement Supplement ... from the reflux classifier will flow by gravity to the fine coal reject dewatering screen for water removal prior to discharging to the rejects conveyor for disposal.

Filtration, 1. Fundamentals

Cleaning and Sizing of Deep Bed Filters . 690 CrossFlow Filtration ... forces is called deliquoring or dewatering,, deliquoring by a pressurized gas or by expres ... a surface filtration with a screen as a filter medium. Its mode of action resembles screening (or

Calculation Of Vibrating Screen

g force calculation formula for vibrating screen « BINQ Mining. Jun 27, 2013 · Vibrating Screen Brochure – Osborn South Africa. All vibrating screens are designed and . The bigger the screen aperture the higher the machine stroke. calculations of size of vibrating screen rock crusher and ... calculations of size of vibrating screen. Case Solution: When we knew that both the capacity and ...

Iron Processing | Equipment, Process Flow, Cases

· Chemical Formula Fe2O3, αFe2O3 (hematite), Fe2+Fe3+2O4 (magnetite) Streak red (hematite), black (magnetite) Mohs Hardness – Crystal System Trigonal (hematite), Isometric (magnetite) Color Metallic gray, dull to bright red (hematite), black, gray with brownish tint in reflected sun (magnetite). Luster Metallic. Related cases. 150TPH Iron Ore Processing Plant in Malaysia 150TPH ...

Appendix N: Tailings and Rejects Management Plan

flotation feed sizing of mm. Caval Ridge Project – Environmental Impact Statement Supplement Page 3 The sieve bend overflow will be discharged by gravity to the fines feed sump while the sieve bend underflow will gravitate to the flotation feed sump. From the fines feed sump the fine slurry of coal will be pumped to the reflux classifier through a feed distributor for even ...

Coal comminution and sizing

· While sieve bends are used for sizing, they are particularly useful as dewatering screens. They may also be used as a prescreening attachment to conventional vibrating screens. The fact that they do not move makes them easier to install and maintain, and cheaper to operate, than vibrating screens. Vibrating screens. Screening machines consist of the support frame that holds the screen .

Latest Posts

- المملكة العربية السعودية توريد ماكينات الجرانيت

- محطة تكسير الحجارة بسعة 100 120 طن في الساعة

- الحجر الجيري الموردين مطحنة الصين

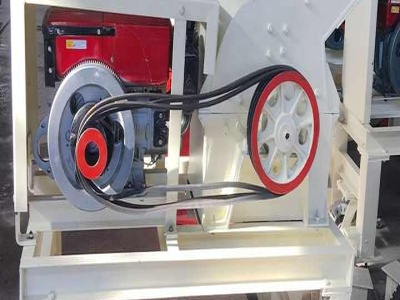

- سلسلة PE كسارة الفك على نطاق واسع

- معالجة طحن الرخام

- أحتاج إلى قائمة الجوائز لجميع سحق الحجر الخاص بك

- قائمة الأسعار كسارة الفك الصين قدرة 65 طن في الساعة

- حيث لشراء كسارة حجر الجديدة في مصر

- كسارة خرسانة للبيع أونتاريو الجزائر

- معدات طحن البنتونيت المصغرة في مصر

- أوروبا تنتج كسارة الحجر

- الحجر الجيري طحن عملية

- معمل طحن ومعالجة الباريت في الجزائر

- تكلفة بناء مصنع الباريت

- تدفق كسارة حجر

- Used Rote Crusher

- Raw Material Transport Analysis From Quarry To Plant

- Off Shore Gold Claims For Sale Off Nome

- Crusher Plant For Sale In Puerto Rico Price

- Conical Sand Grinding Machine In Republic Of Ireland

- Butwal Cement Mills P Ltd

- Laboratory Ball Mill Pictures

- Reasons Which Cause Cement Tube Mill Liner Broken

- Blueprints For Making A Homemade Rock Crusher

- Stone Crusher Pelletization

- Milling In Mines Process Control Design

- 4r Series Raymond Mill Machine For Limestone Calcite Barite Dolomite

- Pemantauan Kualitas Udara Cement Mill Semen Padang

- Impact Crusher Suministro

- Vertical Stainless Steel Slag Stationary Blade