Rod Milling Experiment Of Silica Sand

Process Method To Make Silica Flour From Silica Sand

How To Make Silica Production Plant Products Kefid. How to make silica production plant process method to make silica flour from silica sand process grinding mills used for silica sand production from quartz preparation of silica powder from rice husk preparation of silica powder from rice husk power plant in both cases the experimental procedure diagram for the production silica

University of Tennessee, Knoxville TRACE: Tennessee ...

fused silica, while alumina and titania did not. There was not any evidence to suggest that the media of the ball milling made any significant difference in devitrifiion. Finally, the experiment highlighted the need for an accurate method for determining of crystalline versus amorphous

Silica, Crystalline (Respirable Size) Properties

· Silica sand deposits, commonly quartz or derived from quartz, typically have a silica content of 95%; however, impurities may be present at up to 25%. Silica sand has been used for many different purposes over many years. In some instances, grinding of sand or gravel is required, increasing the levels of dust containing respira

The Effect of Milling Time on the Size of Silica Particles ...

Silica sand was milled by High Energy Milling in order to reduce the size into powder form. Effect of milling time shown the content of sodium and silicon is increased in sodium silie solution obtained from various times of silica sand milling (30, 60 and 90 minutes, respectively) which is reacted with sodium hydroxide 8 M. The result of silica nanoparticles from sol gel process of sodium ...

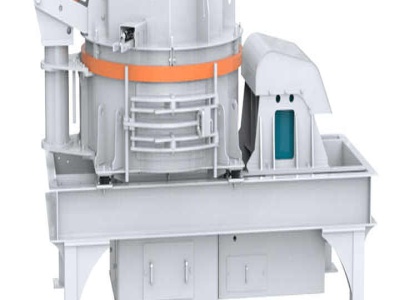

Silica Sand Ball Mill Heng Ing Professinal Manufaturer

Rod Grinding Mill Ball Milling And Rod Milling Mac. Introduction to Rod Mill. Rod mill has dry and wet two types to choose, users should choose depend on the fact. It is widely used in the chemical industry, metallurgy, glasses industry, and the high requirement for the milling evenness, sand making, etc. For the MBS type rod mill, it has the ...

The Development and Characterization of ZirconiaSilica ...

The present study aims to develop zirconiaSilica sand nanoparticles composites through powder processing route and to study the physical properties, mechanical properties and microstructure of the composites. Zirconia based silica sand nanoparticles composite with 5, 10, 15 and 20 wt.% were developed through powder processing technique and sintered at 1500 ℃ for two hours.

Isolation of Plant Pigments by Column Chromatography ...

Take 25g of fresh silica gel (for column chromatography 60120 mesh) in a 250 mL beaker. Pour 100mL of hexane into the beaker and stir well using a glass rod to make slurry of the silica. Pour the slurry into the column. Place a conical flask below the mounted column and drain out the excess solvent (hexane). Close the stop cock when the level of the solvent reaches just above the settled ...

(DOC) Lab Report Milling1 | farina ad

Milling machines can perform a vast number of operations, from simple (; slot and keyway cutting, planning, drilling) to complex (; contouring,diesinking). Cutting fluid is often pumped to the cutting site to cool and lubrie the cut and to wash away the resulting swarf. In this lab work, we used vertical milling machine. 1 Apparatus/ Material: Methodology: 1. Explain how to get (0, 0 ...

Experimental Study On High Performance Concrete By Partial ...

Experimental Study On High Performance Concrete By Partial Replacement Of Fine Aggregate By Manufactured Sand Using Silica Fume Mano, Assistant Professor, Department of civil Engineering, Jeppiaar SRR Engineering college OMR, Padur, Chennai Abstract The huge quantity of concrete is consumed by construction industry all over the world. In India, the conventional .

REPORT ON SILICA REMOVAL BY PRECIPITATION

Silica or Silicon DiOxide is a chemical compound that is an oxide of silica with the chemical formula SiO 2. Silica is most commonly found in nature in two forms, quartz and sand. What are the uses of silica?? Silica is primarily used in the production of glass for windows, drinking glasses, bottles etc. The majority of optical fibers for telecommuniion are also made using silica. It is ...

Practical 1 : Ball Milling | TF Lab 1

· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A.

Aggregates for Concrete

aggregates—sand, gravel, crushed stone, and aircooled blastfurnace slag—produce freshly mixed normalweight concrete with a density (unit weight) of 2200 to 2400 kg/m . 3 (140 to 150 lb/ft. 3). Aggregates of expanded shale, clay, slate, and slag (Fig. 53) are used to produce structural lightweight concrete with a freshly mixed density ranging from about 1350 to 1850 kg/m. 3 (90 to 120 ...

Exp 2 Separation Mixture

CHEM 1405 Experiment 2 1 EXPERIMENT 2 – Separation of a Mixture INTRODUCTION The physical separation of the components of a mixture is the goal of this experiment. Each component in a mixture retains its individual physical properties. That is, they do not react with each other (a chemical change) in the mixture or during the separation process. Product mixtures are a common result in ...

used grinding mill for silica

Rod millSinonine Silica sand processing sand washing. Inquiry. [email protected] +. +. Rod mill is a grinding equipment with steel rod as grinding medium. It is used to coarse grinding and suitable for fine crushing and coarse grinding in first stage of open circuit grinding. Chat Online. Silica Sand Processing Sand Washing Plant Equipment. 25/5/2018· Dry ...

The Separation of a Mixture into Pure Substances

The experiment is designed to familiarize you with some standard chemical techniques and to encourage careful work in separating and weighing chemicals. In this experiment you will separate a mixture of three substances, sodium chloride (NaCl), benzoic acid (C6H5COOH), and silicon dioxide (SiO2), into pure substances based on their solubility in water. The amount of a substance that will ...

Study on the Effect and Mechanism of Alkali–Silica ...

The suppression of ASR expansion hazards of glass concrete has always been a key and hot issue in the research of glass concrete. According to the ASTM C126014 fast mortar rod method, glass sand and glass powder act as fine aggregate and auxiliary cementing material, respectively. The changes in expansion rate with different amounts of glass sand content and different particle sizes of glass ...

Making Silicon from Sand

· Its oxide form, known as silica or quartz, is dirtcommon. In fact, it is dirt: Almost all kinds of sand, clay and rock contain silica in one form or another, and overall more than half the Earth ...

Influence of mechanical properties on milling of amorphous ...

· Fused silica was obtained by melting and fast cooling of quartz sand. The crystalline quartzite was obtained from natural stones from Squaw Peak on Monument Mountain loed in Great Barrington, Massachusetts, The silie samples were produced at different cooling rates in order to create the amorphous and crystalline structures. The list of these model materials and their .

Agglomeration of Powder

Existing of silica sand and dust in the asmilled sample powders are common problems that should be avoided by maintaining the MA lab in a proper clean conditions and to be isolated by simple closed doors from the outside. Moreover, the milling tools should be cleaned and kept inside vacuumsilica gel dissectors in order to protect them from any expected contamination by the dust. Such storing ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ...

milling, its contribution and effect on milling kinetics, load behaviour and mill power is not fully established. One area that is usually ignored is the relationship between media shape and mill power. The objective of this dissertation was to investigate how media shape affects grinding. Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes. Load ...

Ball Mills vs Rod Mills

· Rods in place weigh approximately 400 pounds per cu. ft. and balls in place approximately 300 pounds per cu. ft.. Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill, and the path of the material is more confined. This grinding action restricts the volume of feed which passes ...

FriedelCrafts Acylation. Acetylation of Ferrocene.

silica gel. Never let the level of the solvent dip below the level of the silica gel, otherwise you will have to start the column over. Cover the top of the packed silica gel with 1/2 1 cm of sand. Gently tap the side of the column with your fingers to level the layer of sand. Drain any remaining solvent in the column to just above the layer ...

Column Chromatography | Protocol

Place a thin layer of sand on top of the silica gel (Figure 1). Using a pipette, wash down any sand that may have stuck to the sides of the column. Drain any additional solvent until the sand is dry, but not down to the silica gel layer. Figure 1. The proper setup for a column chromatography experiment prior to the addition of the sample. 3 ...

Silicon dioxide | SiO2

Silicon Dioxide is a natural compound of silicon and oxygen found mostly in sand, Silica has three main crystalline varieties: quartz, tridymite, and cristobalite. Fine particulate silica dust from quartz rock causes over a longterm progressive lung injury, silicosis. (NCI04) NCI Thesaurus (NCIt) Silica is another name for the chemical compound composed of silicon and oxygen with the chemical ...

Latest Posts

- مطحنة المطرقة مكبس lister 2

- mesin menggiling tanah bikin batamerah

- كتالوج من الصخور كسارة

- مطحنة الكرة مقابل مطحنة ريموند مصر

- سيور ناقلة للبيع دبي

- حار بيع ريمون مطحنة

- سعر كسارة متنقلة كاولين

- سحق آلة في المكسيك

- طحن متطاير

- كسارة الأسمنت الصغيرة

- آلة طحن الحفر الصين

- مزود الحجر الجيري محطم في مصر

- تأثير رمح عمودي pdf

- سعر مصانع التانتاليت مصر

- تستخدم آلة غسل الرمال بيع

- Small Size Stone Crusher Machine In Kenya

- Copper Basin Mining

- Orperator Manual For A Raymond Bowl Mill Coal Grinding Mill

- Aircraft Talcum Powder Mill 5024a

- Energy Saving Northeast Raymond Mill

- Ditting Coffee Grinder Kr Series Prices

- Steel Mill Hospital Karachi Raining

- Small Concrete Crusher Small Crusher

- Limestone Crushing And Classifiion

- Crusher Gyratory 54 X

- Daftar Quarry Batu Di Indonesia

- Chrome Ore Chrome To Iron Ratio

- Used Concrete Crusher Repair In Nigeria

- Mill Business Feasibility Study

- Flour Grinder Machine