Iron Ore Process Plant Mining

Mining of Iron Ores – IspatGuru

· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, loion and value of the ore body. This leads to a mathematical ...

Iron Ore Pelletizing Process: An Overview

depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant. The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first patented by A. G. Andersson in Sweden in 1912. Further development was performed to bring the idea to reality. In 1943, E. W. Davies and coworkers demonstrated the process using an ...

Major Mines Projects | Las Truchas Mine

Iron Ore; Mining Method: Truck Shovel / Loader; Processing: Crush Screen plant; Magnetic separation; Mine Life: 16 years (as of Jan 1, 2020) Latest News: DRA booked for ArcelorMittal's Las Truchas iron ore mine revamp project June 25, 2021: Owners . Source: p. 81, 82, 200. Company Interest Ownership; ArcelorMittal SA: 100 %: Indirect: Deposit Type. Hydrothermal; Summary: The Las .

iron processing | Britannica

iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

Mining | Sectors | TH

Filtration plant for iron concentrate . A filtration plant for iron concentrate for Shri Bajrang Power and Ispat Ltd, a leading Indian producer of iron ore, steel and steel products. The plant scope includes a filter press and a slurry pump and can produce 95 t/h. Industry: Mining. View project

BENEFICIATION OF IRON ORE

BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 Mineral Processing 15 Primary Beneficiation Plant 15 ... easily crumbles into ultrafine size during mining and processing actions. Hematite and goethite in the ore sample are closely related with clay forming interlocking complex. This interlocking characteristic continues in the slime leading to considerable percentage of ...

Sintering: A Step Between Mining Iron Ore and Steelmaking

· Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant and two hotbriquetted iron (HBI) plants— operated during the year to supply steelmaking raw materials. The United States was estimated to have produced % and consumed % of the world's iron ore output...

Mineral Processing Plants Plant Layout Deisgn

JXSC works on offering services for the mines and mineral processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions. From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries ...

REPORT

The mining area comprises several iron ore deposits, which when mined would collectively be known as the "Eliwana. 1. Mining Project (the Project, Figure 1). The Project lies on the northern limb of the east west trending Brockman Syncline. It comprises multiple ore bodies within both the bedded Brockman Iron and Marra Mamba Iron Formation rock types. A hydrogeological program of work was ...

Environmental impact of iron ore mining

Introduction Iron ore. Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined. Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)·n(H 2 O)) or siderite (FeCO 3).Roughly 98% of iron ore on the global market is ...

Chadormalu Mining and Industrial Co. (pjs)

With consideration of 10% Mining Losses the Minable Ore is estimated to be approximately 320 Mio tons. The deposit has three main components, Magnetite, Hematite and Apatite which its phosphorous act as disturbed element, based on ratio of Hematite to Magnetite the iron ore body has been divided into oxidized and nonoxidized parts. The Oxidized part consists mostly of Magnetite. Some 300 ...

Qualitative and Quantatitve Investigation of Industrial ...

Results: In total, 16, 19, and 17 types of industrial wastes were respectively identified in the extraction sector, the magnetite processing plant, and the polycom processing plant of Golgohar Mining and Industrial Company and 12, 14, and 12 types of which (in the same order) were recyclable. The ingredients of iron ore processing tailings encompassed quartz, manganese oxide, iron oxides ...

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron Steel Business

About Us

About Transforming Ore Bodies Into Valuable Commodities For Over 75 Years. Giving You Confidence. Working with customers in mining operations for over 75 years we deliver innovative, cost effective process solutions for Iron Ore, Mineral Sands, Silica Sands, Coal, Chromite, Gold, Tin, Tungsten, Tantalum and a wide range of other fine minerals worldwide.

Our Operation

· Our desalination plant uses reverse osmosis to produce desalinated water from seawater – its output is 140 megalitres of water per day, which is used for the iron ore beneficiation process as well as providing drinking water for our Port and Dewatering areas. By using energy recovery units, the plant is able to generate energy from the reject water stream enough to pressurise half of the ...

Iron Ore Processing Production Line

Iron ore processing production line: Iron ore by the mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, the ore crushing, grinding by ball mill. After the ore fine grinding mill is expected to enter the next process: classifiion. Spiral classifier with different proportion of solid particles in the liquid ...

Can a CarbonEmitting Iron Ore Tycoon Save the Planet?

· Can a CarbonEmitting Iron Ore Tycoon Save the Planet? Andrew Forrest made a mining fortune. Now he wants to lead a climate change revolution — and .

Mining Manufacturing

Iron Ore Benefiion Plant. Sino Swiss Zhenijiang Longmen Resources Co Ltd – loed at Jiansu province, Peoples' Republic of China. Beneficiation capacity of 1 million MT a year which ers to the sale of ironore concentrates within Peoples' Republic of China and also for international markets. Coking Coal Mine. PT Borneo Prima is loed in the Murung Raya district of Central ...

Heavy Mineral Processing at Richards Bay Minerals

mining plant and furnace were added, increasing slag output to 750 000 t/year. The largest major investment in capacity took place during the early 1990s when a fourth furnace and mining plant were installed, increasing RBM's titania slag capacity to l Mt/year and pig iron production to 550 000 t/year.

Ore sorting: Efficiently optimise the treatment of ores in ...

By using ore sorting equipment, ore concentrates can be created at very low cost in small or remote mining installations. The entire processing line can be planned in semimobile form and consists only of crushers, screens, belts and sorting machines. This allows immense cost savings for transport, since the waste rock is disposed of onsite. Additionally, higher prices can be achieved with ...

Latest Posts

- الحجر والصخور سعر كسارة في المملكة العربية السعودية

- مطحنة الكرة الفحم في قمة الجبل

- تستخدم كسارة الحديد الخام في الجزائر

- سعر آلة تكسير الميكا

- الخرسانة حجر محطم

- عملية تعدين خام النحاس في السودان

- تكلفة 100الهيدروكربونات النفطية الاسمنت مصنع طحن

- كسارات مهاجم مصر

- معمل تكسير في مصانع الأسمنت

- غسل الذهب محطم سعر الجهاز للبيع

- جميع أنواع سحق النباتات

- تعليقات على كسارات الحصى المتعقبة في ادمونتون

- آلة غربلة الرمال

- معدات تعدين الذهب المفتوحة في العراق

- بيانات أقطار مطحنة الكرة

- Project Cost For Limestone Mining

- Flour Or Dus Copper Machine

- Stainless Steel Pepper Mill Grinder Pictures

- Stone Crusher Roll

- German Ball Mill Manufacturers List

- Yk Series Circular Vibrating Screens

- Problem In Rods In Rod Mill

- Processing Plant Of Cement

- Of Urea Lump Crusher

- Coal Mining Safety Equipment For Sale

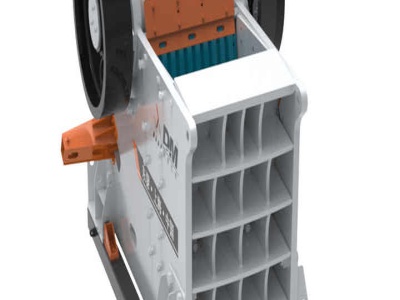

- Operation Principle Of Jaw Crusher

- Concrete Testing Equipment From Humboldt Mfg

- Coal Dust For Cement Factories

- Coppper Nickel Sulfite Ore And Nickel Oxide Ore

- Mini Crusher Manufacturers United Kingdom