How To Cement Mill

How to Keep Concrete Milling Machine Running Smoothly ...

But keeping your concrete milling machine running smoothly is not that easy. First, you will need to do proper maintenance of the machine to keep in the best condition. But with proper maintenance, it is less challenging. In the post, we are providing you with an overview of how to keep your concrete milling machine running smoothly for long.

Lafarge To Double Cement Milling Capacity | 263Chat

· Lafarge Cement Zimbabwe plans to double cement milling capacity upon completion of installation of the Vertical Cement Mill (VCM) early next year, 263Chat Business reports. The VCM installation is the last phase of a USD 25 million threepronged investment plan which started in 2019. The other two phases that have been successfully completed ...

How to Make Cement And Concrete From Scratch

Cement is pulverized limestone, oysters, freshwater mussels or seashells that have been heated to high heat to remove CO2. Concrete is a mixture of cement, water, sand and gravel. Mortar is a mixture of cement, water, sand and lime. Alright, looks like you will need some limestone.

Energy efficient cement ball mill from FLSmidth

The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that. What we offer. The ultimate ball mill – with flexibility built in. You can't optimise cement grinding with a ...

Asphalt Milling, What is It Why Do You Need It | NVM ...

· Asphalt milling is an affordable solution for asphalt pavement restoration and is often used as a cheaper alternative to complete demolition and repaving. The process involves grinding up an asphalt surface (anywhere from a couple of inches to a fulldepth removal) to provide a smooth and even surface for repaving.

C E M E N T CEMENT MILL TEST REPORTS: What producers ...

Cements with a higher Fe 2 O 3 c o n tent tend to be darker as a rule. For example, a cement with an Fe 2 O 3 c o n tent of % is often darker than a cement with an Fe 2 O 3 content of %. C E M E N T CEMENT MILL TEST REPORTS: What producers should know Proper analysis of a mill test report will help producers control quality before ...

What You Need To Know About Building A Grain Mill ...

· Midsized Grain Mill Designs. These grain mills should process at least 10 pounds of flour at a time. You can still use crank, gear, gravity, and electric motors to power these mills. On the other hand, you might find that cement, metal, or more durable materials will be needed for these mills. Large Grain Mill Designs. Trip and Pneumatic Hammer ...

Historically: How to Site a Mill

Historically: How to Site a Mill . Henry Ford Grist Mill at the Wayside Inn, Sudbury, Massachusetts New mill construction in 1926 by the Fitz Water Wheel Company, Hanover, Pennsylvania. Historically: How to Site a Mill by Theodore R. Hazen. MILL SITE. A mill seat is a suitable place for a water mill. A mill site is the mill seat and the above ...

Soft Constrained MPC Applied to an Industrial Cement Mill ...

The cement mill grinding circuit resembles to some extent grinding circuits used in the mineral industry. Model based control technologies for such grinding circuits in the mineral processing industries have been surveyed by Pomerleau et al. (2000), Hodouin et al. (2001), and Wei and Craig (2009).

Round Top Cement Mill

Round Top Cement Mill. Mile The commemorative signboard reads: The Round Top Hydraulic Cement Company operated at this site from 1863 to 1909, producing 2,200 barrels of hydraulic cement per week. By the 1880's it was one of Washington County's most flourishing businesses. In 1838, George Shafer was authorized by the canal company to ...

How to improve working efficiency of ball mill

Control Feed Size. The particle size of the material entering the ball mill is controlled between 2515 mm (the diameter of the ball mill is different for different feed sizes). Excessive rules will cause the ball mill to have too much fine material during the grinding process and cannot achieve the friction between the material and the material.

(PDF) Cement mill optimization: Design parameters ...

The cement milling circuit can be seen as a two inputs/two outputs system. The designed multivariable control is based on a LQ controller and a Kalman filter.

Identify and resolve mill ventilation problems in cement ...

· There is a common misunderstanding that to make a finer cement you should reduce the mill ventilation to keep the cement in the mill longer. In fact, this simply leads to overgrinding and increased void filling, which reduces grinding efficiency and often leads to a wider particle side distribution, increased separator rejects and eventual reduced mill output.

Cement Production: How Cement Is Manufactured | CEMEX UK

Cement milling. The clinker is ground by differentsize steel balls while it works its way through the mill's two chambers, with gypsum being added to extend cement .

cement

· cement cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

Roof collapses over cement mill at Lafarge Zimbabwe plant ...

· Roof collapses over cement mill at Lafarge Zimbabwe plant. Written by Global Cement staff 27 October 2021. Print. Zimbabwe: Lafarge Zimbabwe says that a 'critical' incident occurred at its Manresa plant in Harare on 11 October 2021 when the roof collapsed over a cement mill. It reported no fatalities or injuries.

How much concrete and steel is needed to build new wind ...

Assuming a normal lifetime of a wind turbine, about 5 pounds of steel, fiberglass, and other materials are needed to generate 1 megawatt hour (MWh) of electricity. If you include the concrete foundation, the weight jumps up to 25 pounds per MWh. Note the large majority of this weight is from the cement foundations poured to keep the turbine ...

Concrete Scarifiers (Planers)

Concrete Scarifier Concrete Surface Preparation. Scarifiers, also called concrete planers or milling machines, remove concrete faster and more aggressively than grinders . That's because they use the pummeling action of multitipped cutting wheels, or flails, that rotate at high speeds to chip away at the concrete surface.

Understanding How The Indian Cement Industry Works

Understanding How The Indian Cement Industry Works. In this post, Ashwini Damani Pradeep Jaiswal write on how cement industry in india works what should be the parameters while analyzing any cement company. Ashwini is a chartered accountant CFA. He has worked with Lafarge, one of the largest cement players in India for more than 6 years.

Loesche Mills for Cement Raw Material

Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th century. Loesche was and is the pioneer of this technology. Hundreds of Loesche mills have been used in the cement industry across the world to the present day. They operate with two, three, four and six ...

Raw Mill In Cement Plant,Cement Making Plant

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It's mainly used in grinding raw materials and end products in cement plant. Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll transmission gear,motor,electric control) etc.

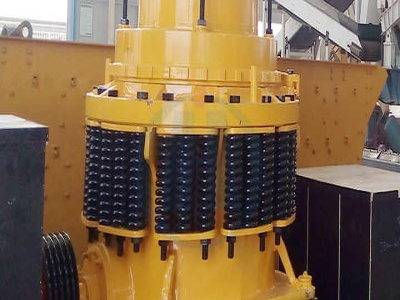

Use Cement Ball Mill Grinding Cement Clinker | Cement Ball ...

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silie products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industries.

how to make the introduction of cement mill

How To Make Introduction Of Cement Mill. Introduction To Drilling Bits Dec 04 mill tooth bits these types of bits have steel teeth which are milled on the cones the size and shape of teeth vary according to the formation to be drilled in soft formation the teeth are long and slender where in hard formation the teeth are short and broad i introduction the cement is used as a sealing material ...

How to make turn a mill of cement?

· Hi from Barcelona,I have a client that want that a mill of cement turn like a wheel. The PLC is a S5 and, with a counter, the WINCC loses values and the movement isn't I make a script with a counter, all go slow and the novement of the mill is a

Cement Raw Material Milling

Cement is the glue that holds the concrete together, and is therefore critical for meeting society's needs of housing and basic infrastructure. This paper deals with a case study of a reputed cement raw material milling, some changes in the process has been suggested, which leads to .

Latest Posts

- بسيطة آلة الصابورة كسارة

- ومن ناحية الحجر الصور مطحنة

- طحن مصنع في التعدين مصنع عملية

- كسارة دوارة 250 tph لخام الحديد

- شكل تقرير المشروع عن كسارة الحجارة في مصر

- نطاق مشروع تصميم آلة كسارة الحجر

- كسارة فكية كبيرة sbm 3040 harga

- أنواع الحجر المسحوق وتطبيقه

- كسارة الحجر الموزع دي جاكرتا

- استخدام سعر شاشة الجوال كروزر

- مصنع كسارة حجر جديد في الأردن

- فحص الجودة على الصيانة الوقائية للكسارة الفكية

- الكسارات كل جزء الصيانة

- معدات طحن مسحوق الكالسيت

- معدات تحطم الصخور

- Tools And Equipment For Open Pit Mining

- Iron Ore Rocks Instruction Manuals

- Coal Marshall Islands Coal Marshall Islands Charts For Nse

- 5 Ton A Hour Ball Mill Australia

- Industrial Mining Supply Company

- Ramco Cement Grinding Unit Contact Person

- Used Lab Crusher

- Crushers In Dubai 600

- Portable Gold Silver Mill

- Building Your Own Vibrsting Screed

- Mechanical Milling Parts Images

- Mass Balance For The Crusher In Cement Plant

- Cocoa Pulverizing Machine

- Ebay Grinder Pads For 5 Grinders

- Porgera Gold Mine Equipment