Power Plants And Coal Mills

Increasing the flexibility of coalfired power plants

Increasingly, coalfired power plants are required to balance power grids by compensating for the variable electricity supply from renewable energy sources. For this, high flexibility is needed, in terms of possessing resilience to frequent startups, meeting major and rapid l oad changes, and providing frequency control duties. This report reviews the means available and under development for ...

Coal Mills In Thermal Power Plant

Minhang Power Plant, Shanghai Electric Power Co., Ltd..99 Мб 2. For coal mills A and C that operated under a 100 MW load, the measured boiler efficiency improved by % when the combustion optimization system was put into service; thetested parameters according to the emission standard of all pollutants for thermal power plants GB.

COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR .

· COAL MILLS FOR THERMAL STATIONS Coal Pulverizing in Boilers. Pulverizing coal for a boiler is very important factor in overall cycle efficiency. There are many types of pulverizers available, but proper selection will ensure consistent boiler and cycle efficiency. This helps in reduction of carbondioxide emission per million units of electricity generated. Boilers for steam generation in ...

TECHNICAL SPECIFICATION FOR AGRO RESIDUE BASED BIOMASS ...

agro residue cannot be directly utilized in thermal power plants as coal mill are not designed to pulverize the fibrous biomass and same needs to be densified and processed to form the pellets having pre pulverised fine constituent particles. The densified biomass pellets/ torrefied pellets can be fed to the mills and easily crushed with coal for firing into the boiler. Considering merits of ...

mill area operation in thermal power plant

mill area operation in thermal power plant. mill area operation in thermal power plant. Big Bend Power Station Wikipedia Know More. Big Bend Power Station is a major coalfired power plant, loed across Tampa Bay from Tampa, Florida on nearly 1,500 acres (6 km 2) in southeastern Hillsborough County, close to Apollo BeachIt is owned and operated by TECO EnergyThree similar units ...

Boiler House and Mills

The boiler house at Eggborough Power Station contained the steam generating boilers and pulverised fuel mills. The four reheat boiler units were manufactured by Foster Wheeler / John Brown, were single furnace, front wall fired, natural circulation water tube boilers. The boilers had an evaporation capacity of 422 kg/s at 165 bar. The superheated steam temperature was 568°C.

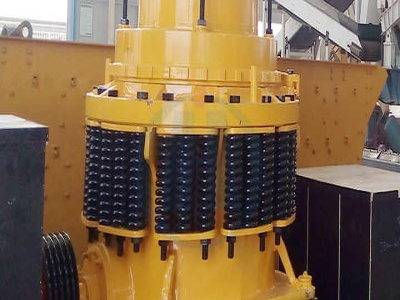

Mills For Coal Power Plant

Coal mills of power plant pulverizer wikipedia overviewtypes of coal pulverizersbeater wheel millhammer milldemolition pulverizer a pulverizer or grinder is a mechanical device for the grinding of many different types of example, a pulverizer puritch is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants. Mills For Coal Power Plant ...

Coal Mills For Power Plant In United States

Coal Mills For Power Plant In United States May 05, 2021 For the twelve months ending in March 2013, United States' coal plants produced 1,517,203 gigawatt hours of electricity, or percent of total electricity production.

Thermal Power Plant Coal Mills

Description of coal mills in thermal power plant coal mills in thermal power plant is also called raw meal vertical roller mill and it is the core equipment applied for cement raw meal grinding In 1971 first 1m ball mill in China was produced in Great Wall Machinery and open the door to. Get Price ; Increasing The Flexibility Of Coalfired Power Plants. Increasingly coalfired power plants are ...

coal mills used power plants

coal mills used power plants. Abstract In order to achieve high performance and efficiency of coalfired power plants it is highly important to control the coal flow into the furnace in the power plant This means suppression of disturbances and force the coal mill to deliver the required coal flow as well as monitor the coal mill in order to detect faults in the coal mill when they emerge

Predictive control strategy for a supercritical power ...

Predictive control strategy for a supercritical power plant and study of influences of coal mills control on its dynamic responses Abstract: The paper is to investigate dynamic responses of supercritical power plants (SCPP) and study the potential strategies for improvement of their responses for Grid Code compliance. An approximate mathematical model that reflects the main features of SCPP is ...

Coal Hangup in Bowl Mill Operations

· There are many types of mills and bowl mill is one of them, all these mills can face coal hangup. For taking corrective action during a coal hangup in bowl mills the operator will have to know the reason for such a hangup, how the plant will respond, what he has to respond to and what the local operator will have to do. This will reduce the chance of mill trip and bring back boiler to ...

power plants and coal mills

coal mills in power plant Coal powder mill applied at coal fired power plant and thermal coal power plant and other plants. coal mill at power plant area, gold,copper,iron ore crushers coal mill at power plant area Limestone crushing industry Indai rock crusher plants made in germany belt conveyor used for sale feed size for ...

thermal power plant coal mills

thermal power plant coal mills. Thermal Power Plant. 201973 coal is the mainly energy consumption, so it is the main problem to improve coal fired efficiency for thermal power plant traditional ball mill has large power consumption in the process of production, and fineness of pulverized coal .

power plant coal mills

Coal mill pulverizer in thermal power plants. Nov 17 2012 · pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner

Any Plants And Mills Want Coal

Any Plants And Mills Want Coal. Fossil Fuel Power Station Wikipedia. A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or All plants use the energy extracted from expanding gas, either steam. Prices / Quote. Power And Smoke A Nation Built On Coal American Radioworks . Barbara Freese They saw all of this coal here as a gift from God further evidence ...

Coal Mills Portable Power Plants

Coal mills for power plant. coal mills for power plant. Get of silica sand mining process equipment for a response to the desaster at the Fukushima nuclear power plant I've heard the claim that fossilfuel power plants using coal release radiation than a nuclear. Coal mill pulverizer in thermal power plants. Nov 17, 2012 pulverizer mill system One of the critical power plant ...

Coalfired power plant and pulp and paper mill site

This industrial complex includes a 400 MW coalfired power plant consuming 900,000 tons/year of coal and a pulp and paper mill producing 500,000 tons/year of paper. The power plant uses coal and biomass, rice husk and wood bark, for fuel. The scope of mercury releases from power plants depends in general on the content of

COALFIRED POWER PLANTS

COALFIRED POWER PLANTS. The safety and efficiency of modern thermal power plants relies on accurate measurement and careful . control of operating conditions. Employing many decades of experience and expertise, AMETEK Land . provides instrumentation and monitoring systems that are ideal for: • Monitoring coal transport, storage and preparation • Maximising efficiency of coalfired ...

mills for coal power plant

Coal Mill In Power Plant Crusher Mills Cone Crusher . about coal mill in power plantGrinding Mill China Mills and pulverisers for coal and oil power plants Alstom Take advantage of Alstom s global experience and industry expertise Coal Mill In Power Plant With ImagesGold Ore. Chat Now ; What are the appliions of ball mills in coalfired . 2017/02/20 · Ball mills are used primary for single ...

Is it possible to take coal mill in service before turbine ...

Answer (1 of 5): Yes you can of course, to take coal mill in service does not related directly to whether turbine synchronised or didn't. Its more regard to boiler ...

Proximity to coalfired power plants and neurobehavioral ...

Introduction. Coalfired power plants that are a major source of toxic air pollution including SO 2, NOx, particulate matter ≤10 μm (PM 10), and particulate matter ≤ (PM ) can adversely impact residents' health in the nearby communities [1, 2].In addition to pollutants that are emitted from the stack of power plants, communities may be exposed to coal ash, which is a waste product ...

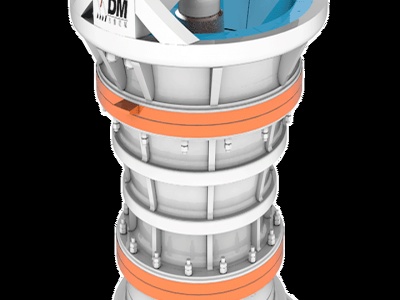

Pulverizing Mills | Thermal Power Plant

Thermal Power Plant. All about Infrastructure Home; Pulverizing Mills. Each of the six units at Drax has ten pulverising fuel mills, each capable of pulverising 36 tonnes of coal per hour. Inside the mills, ten giant hollow steel balls, each tonnes in weight and approximately 730 millimetres in diameter, crush the coal into a fine powder. Crushing the coal into a fine powder makes it ...

China To Build 43 New CoalFired Power Plants – Watts Up ...

· China is planning to build 43 new coalfired power plants and 18 new blast furnaces — equivalent to adding about % to its current annual emissions — according to a new report. The new projects were announced in the first half of this year despite the world's largest polluter pledging to bring its emissions to a peak before 2030, and to ...

MRHS

MILL REJECT HANDLING SYSTEM IN THERMAL POWER PLANT (MRHS) May 20, ... Mill Rejects from coal mill will drop into the Pyrite Hopper through the grid. Oversize material will be retained on the grid. A pneumatic cylinder operated Plate Valve on oversize material discharge chute will be provided, which will be operated automatically in case of accumulation of oversized rejects. Mill outlet valve ...

Latest Posts

- حجر كسارة dememer

- صور الحجر الأبيض المسحوق

- خام الحديد معدات سحق الصين

- سحق الصناعات الاردن

- تشغيل مصنع الاسمنت

- كسارات الفك المصنوعة في مصر

- كسارة خام الحديد نوع الإنتاج

- تكلفة سحق الصخور لكل طن فك مقابل كسارة تصادمية

- مطحنة الكرة مطحنة الكرة تعدين الذهب مطحنة الكرة سيليكات

- مصنع كسارة الصخور المتنقلة العقيق

- سحق وطحن كسارة محجر النحاس

- كسارة الحجر لإيران

- السعر محطة كسارة متنقلة

- قطع غيار تكلفة الحزام الناقل

- مبيعات مطحنة الكرة في اليمن

- Mobile Stone Crusher Prices

- New Used Universal Crushing Plants For Sale Rental

- Mobile Crushers For Coal

- Jyoti Industries Pulverizer

- Normal Speed Of A Conveyer Belt In Plc

- Bauxite Mining In Saudi Arabia

- Zimbabwe Cost Price Of Grinding Mills

- Brazilian Granite Uranium Mines

- How A Jaw Crusher Works And What It Is Used For

- Grinding Mill Products Suppliers Manufacturers

- Gold Recovery Vibrating Tables

- Underground Gold Mining Machinery

- Ball Clay Grinding Equipment

- Barite Milling In Nigeria Stone Crusher Machine

- Metal Crusher Sri Lanka