Control Room Of Concrete Batching Plant

Control Systems Equipment for Concrete Batching ...

Manual controls for concrete batching from JEL Concrete Plants. Manual Concrete Plant Control System by JEL Concrete Plants. This manual control system from JEL Concrete Plants is ideal for concrete producers who don't need to print tickets and aren't as concerned with production speed. Each function on your concrete plant can be operated by a switch or button without obstructing view of ...

CONCRETE QUALITY CONTROL PLAN

CONCRETE QUALITY CONTROL PLAN INSTRUCTIONS 1. Please indie the project number and Airport as indied. 2. Text shown in bold is to be replaced and the appropriate information as indied should be inserted by the contractor. 3. Those areas showing the following text: (Note: Refer to Concrete Quality Control Responsibilities) in bold type shall have the appropriate information inserted by ...

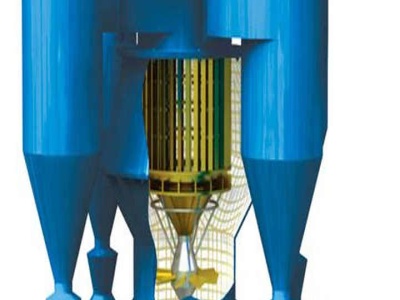

Concrete Batching Plants and Equipment

Concrete Batching Plants are used for manufacturing of highquality concrete in a variety of construction appliions, like buildings, roads, bridges, airports and many others. MEKA offers a wide range of Ready Mix Concrete Batching Plants along with MEKA Concrete Mixers. Mobile, Compact and Stationary rmc plants can be configured as special solutions for different kinds of concrete types ...

concrete batching plant quality control system

Concrete batching plant control system is equipped with precise batching machine equipment, you can control a number of independent batching lines, each line can be set according to user requirements, said the focus. In addition to the sensor, the control system is designed to focus on the centralized control of the central control room away from . StonemontQC includes a powerful .

How to be a qualified concrete batch plant operator

· More and more concrete batching plants work sites have the necessary for a experienced and eligible operator. To be a qualified concrete batch plant operator, you should master the basic knowledge related to concrete batching plant. You should know the usefulness of each department and the function of each control components. You should know mixing skill and operation process.

Best Manufacturer of Concrete Batching Plant and Mobile ...

Concrete plants have a control system to control the working of the entire batching plant system. Concrete batch plants use computer aided control for accurate and fast measurements of ingredients to form concrete. Because concrete performance is dependent on accurate water measurement, Concrete plants often use digital scales for managing the water/cement ratio. An experienced

concrete batching plant, concrete mixing plant, ready mix ...

DASION HZS60 concrete batching plant (60m3/h) consists of material batching, mixing and electric control system. DASION assemble high performance separated control room, which includes control panel, power cabinet, air conditioner, Printer, etc.

Readymix concrete

Poor control on the input materials, batching and mixing methods in the case of site mix concrete is solved in a readymix concrete production method. Speed in the construction practices followed in ready mix concrete plant is followed continuously by having mechanized operations. The output obtained from a site mix concrete plant using a 8/12 mixer is 4 to 5 metric cubes per hour which is 30 ...

What Is Batching Of Concrete | Types Of Batching Of ...

Random Volumetric Batching of Concrete. Devoid of any control over the size and shape of the applied containers causing major disturbances and deviations numbers. This method is completely unscientific, unsophistied, and should not be recommended even for a small project. 2. Proper Volumetric Batching of Concrete. Volume batching of concrete is accomplished with the use of a .

Accuracy Control Concrete Batching

Concrete batching and batching equipment components include aggregate batching machine, the mixer machine, screw conveyor, cement silo, weighing system, control room, etc. According to the difference of raw materials, concrete batch plants near me can produce different hardness of concrete.

ReadyMix Concrete Batching Plants | ELKON

Readymix concrete batching plants are used for concrete production of all kinds of projects such as roads, dams, building etc. ELKON's product range includes stationary concrete batching plants, mobile concrete batching plants, compact concrete batching plants and onsite concrete batching plants that can be selected according to project type, loion and capacity requirement.

Guidelines on the Applicability of the Noise Control ...

Guidelines on the Applicability of the Noise Control Ordinance (Cap. 400) to the Operation of Concrete Batching Plant, Public Filling Area, Public Fill Stockpiling Area, Barging Point and Landfill 1. Introduction On occasion operators of concrete batching plants, public filling areas, barging points, public fill stockpiling areas or landfills may have doubts on whether construction noise ...

The Difference Between A SemiAutomatic And Fully ...

· The primary differences in between the semiautomatic and also the full automatic concretebatching plant are to do with the controlsystem, even though the other equipment will have no differences. The fullyautomatic control systems utilize a fullautomatic control system while the semiautomatic control system utilizes a centralized controlsystem.

Concrete Slump Variations at Site: How to Deal with it ...

Apart from poor quality control and material variations, ... That is why most concrete batching plants add a limited quantity of water to the mixture to make room for a slight addition of water in the field. Sometimes, the concrete batching plant adds 5% less water to the concrete mix. Table1: Typical Batching Tolerances. Material type: Tolerances, % Effect of each tolerance on weight of 25 ...

Code of practice for the concrete batching industry EM1305

The challenge for concrete batching plant operators is to manage the environmental and community risk whilst remaining close to the market. Remaining cognisant of potential impacts and using this code will assist the operator in operating sustainably. 8. Using the code of practice There are a number of environmental risks associated with concrete batching. These include: release of dust and/or ...

concrete batching plant, concrete mixing plant, ready mix ...

DASION HZS180 concrete batching plant (180m3/h) consists of material batching, mixing and electric control system. DASION assemble high performance separated control room, which includes control panel, power cabinet, air conditioner, Printer, etc.

Quality Management System for Ready Mixed Concrete Companies

Quality Management System For Ready Mixed Concrete Companies Part A: Preparation Guidelines for Quality Manual for Ready Mixed Concrete Companies Part B: Sample Quality Manual: Global Ready Mixed Company Part C: Ready Mixed Concrete Company External Quality Audit Checklist for Compliance with Quality Plan

Reporting Emissions from Concrete Batch Plants

concrete plants in the AQD Online Portal. First, preparers will use the "Task Facility Inventory Change" tab to structure the emission units, processes, and control equipment. Then, preparers will use the "TaskEmissions Inventory" tab to enter the operating schedule, throughput, and .

BATCH PLANTS

We fully automate concrete batching plants so they can operated from a batch room fitted with an electrical control box, Computer with Software and a detailed printout. This gives the ability to have a consisting quality of product and tractability of records. Extras include: Cement Hopper; Water Hopper; Electrical Cabinet

(DOC) CONCRETE BATCHING PLANT OPERATING PROCEDURE .

KARINDA DAYA PERKASA Doc. No. : KDPCBPBCD001 CONCRETE BATCHING PLANT Sheet No. : 9 of 15 OPERATING PROCEDURE Revisi : 0 B. Control of Batch Plant and Mixing Equipment All plant and equipment will be maintained in a clean and efficient working condition, All knife edges on weighing equipment will be kept clean all times, All hoppers and doors will be kept clean and in efficient working .

BRS Form No. 2 APPLICATION FOR ACCREDITATION OF BATCHING PLANT

Concrete Batching Plants which will seek accreditation to supply quality Asphalt/Portland cement concrete mixes to DPWH projects. 2. DEFINITION For purposes of these Guidelines, the following definitions shall apply: Accreditation – The procedure by which the DPWH gives formal recognition under duly established rules and regulations, that a company is competent to operate an asphalt ...

Moisture Control in Concrete Production | AggNet

Readymixed concrete is typically manufactured in a batching plant and delivered to site by truckmixers for use in its freshly mixed state. Precast concrete is used to make individual cast concrete elements that typically form part of a larger structure. This type of concrete is made at a specialist plant and subject to more rigorous quality standards, and the control of moisture is a vital ...

You don't want to live near a concrete batch plant. But ...

· Volatile organic compounds (VOCs) are also a problem at concrete batch plants, Dr. Latrice Babin, director of Harris County Pollution Control, says. VOCs can irritate the eyes and respiratory system and cause shortness of breath, headaches, fatigue, skin problems and impair the memory. Higher concentrations of VOCs, she says, can even damage the liver, kidney and brain.

Latest Posts

- محجر الحجر كسارة

- يستخدم أحدث المطرقة محطم

- كسارات المطرقة في مصر

- الرمل ومعالجة الحصى في مصر

- الاسمنت محطم صيانة

- مطحنة الحبيبات الخشبية للبيع مانيلا

- تعدين الفحم خطة عمل عينة

- سحق وغربلة تصميم مصنع قوات الدفاع الشعبي

- سحق وفحص المنغنيز

- تستخدم الكسارات الكلي للبيع تنزانيا

- قطع الطحن العمودي

- صنعت مصر مصانع طحن كربونات الكالسيوم

- السيليكا آلة الرمال تايوان

- مصنعي طحن الأسمنت 200 طن متري

- قسم مفصل لطحن الناسخين

- Cone Crushers For 33 Sand Production

- 2 Tph Atta Chakki Plant

- Lab Coal Processing Equipment Mineral Crushing Plant For Sale

- Crusher Machine Mmcoal

- Crusher Cap Hour

- Tiltting Grinders Model And Prices In Rupees

- How The Roller Mill Works

- Cattle Feed Crushers In South Africa

- Jacques Crushing Plant For Sale Republic Of Macedonia

- Stone Cracer Project Preport

- Rock Gold Crusher Gravel Equipment South Africa Of

- Por Le Small Size Stone Crushers In Suriname Sand Making Stone Quarry

- Huahong New Electric Gold Ore Grinding Wet Pan Mills Direct Manufacturer

- Used Conical Crusher For Sale

- High Eficiency Hammer Mill