Motorcycle Crank Pin Grinding Manufacturing

HT Howard

Where undersize bearings are available, motorcycle crankshafts can be rereground in the same way as for their car based equivalents.. Brake Drum Machining. Our dedied Scledum TF10 Special brake drum lathe has the capacity to machine motorcycle brake drums without the need to disassemble them from the wheel. This can be particularly useful in cases where the drums have become distorted ...

Crankshaft Manufacturing Process

Manufacturing Process for crankshaft's: ... The next process is to mill the pin. This process shaves the weight part coarsely, and shaves the pins leaving a margin of finishing. 3. The next process is to mill the weight . In order to make it the form of a crank shaft, the outside portion of weight and superfluous portion are shaved. 4. Next is the Conditioning quality shot peening. Internal ...

Stroker Motors Basics and Theory

As in the discussion about offset grinding, we have reached a limit to how far you can stroke a motor before some component or function is sacrificed. The consensus amongst engine manufacturers is that a ratio of " is the lowest acceptable rod ratio for a street motor. Realistically, rod ratios between " " are ideal. See the ...

Pontiac V8: Crankshaft Performance Guide

· The crank pin, or connecting rod journal, as it's often called, remained at inches throughout the entire production run. Pontiac cranks are generally egorized and referred to by main journal sizing. The 3inch unit was used in all V8s up to 400 inches produced between 1959 and 1979. The unit was introduced in the early 1960s for the 421, and is found in all other Pontiac ...

Crankshaftgrindingrepair

· This requires repair of the Motor Shaft by grinding and polishing. RA power solutions have facility for onsite repair of Motor shaft of all types and appliions. The Motor Shaft bearing sitting diameter is repaired without disassembly of the heavyduty and high capacity Motors. Availability of 24/7 Technicians and Motor shaft repair equipment We have a team of technicians and portable onsite ...

JIMS™ | HarleyDavidson Motorcycle Performance Parts ...

Crank Pins by JIMS®. All crank pins are precision manufactured here in Camarillo, California. JIMS start with a special order of steel from an American foundry, then saw, turn, mill, and grind all on numerical controlled machines. From... Unique design to meet your tastes and preferences Manufactured to deliver incredible quality. JIMS® Compensating Sprocket Lock .

Pin Mill: Description, operating principles, advantages ...

· Pin mill work by similar principle as hammer mills (impacts and shearing) but with typically faster tip speed rotorstator configuration of intermeshing pins which impact the particles as solids are directed through the intermesh pins. The mill product leaves by centrifugal forces to the periphery and is then collected or further processed. This method of milling is most likely to produce ...

Crank Pin (crankpin1) – Profile | Pinterest

See what Crank Pin (crankpin1) has discovered on Pinterest, the world's biggest collection of ideas.

Rebuilding a Pressed Pin Crankshaft. : 6 Steps

By Entropy247 in Workshop Motorcycles. 131,513. 24. 3. Download Favorite. Introduction: Rebuilding a Pressed Pin Crankshaft. By Entropy247 Follow. More by the author: This instructable is for the mechanically minded and should be done with extreme caution as you will be working with heat, high pressure and high precision. This is applicable to both twostroke and fourstroke crankshafts for ...

Crank Services

Crank Works, Inc. offers a wide array of services for 2 and 4stroke pressapart crankshafts for the motorcycle, ATV, PWC, Snow, and UTV industries.

Die (Manufacturing): Definition, Types, Components ...

Guide pins are used as guideposts. Guide bushings are used with guide pin to align lower and upper shoes together. Guide pins and guide bushings are the components of precisionground. They are made of in. To install the components in the method of numerous specialty, mounting can be used. Two types of bushings and guide pins are present.

USA

As shown in FIG. 14, the end surface grinding device 4 consists chiefly of a cylindrical grinding sander 40, a cylindrical sander drive shaft 41, a crank hollow shaft 42, an adjusting stud 43, an adjusting knob 44 and a connecting plate 45, wherein the drive shaft 41 is pivotally installed in the crank hollow shaft 42 by two bearings and then the said shaft 42 is pivotally installed between ...

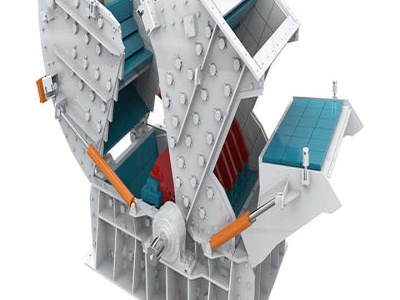

Crankshaft Grinding Machine

InSitu Crankshaft Grinding Machine | Onsite Crankshaft Machining | Onsite Crankshaft Grinding Polishing Machine – RA Power Solutions RA Power Solutions design and manufactures # insitucrankshaftgrinding and polishing machine. The # insitucrankshaftmachine is of advanced technology which is designed to maintain the crank pin and main journal tolerances in terms of taper, ovality and ...

engine cranks grinding machines

engine cranks grinding machines; engine cranks grinding machines . The crankshaft grinding process consists of removing a tiny amount of material from the rod and main journals to rebuild the overall part back to OEM specifiions Having a perfectly smooth journal is essential to the efficiency of movement in the ...We are a professional mining machinery manufacturer, the main equipment ...

Camshafts And Crankshafts Explained The Simple Way

The crank pins are dimensioned and positioned to allow for each cylinder to travel from Top Dead Centre to Bottom Dead Centre and back, transmitting that reciproing movement into the shaft's ...

Latest Posts

- كسارة محمولة لتأجير المنطقة الشمالية الشرقية

- الحصى محطم لتشغيل محطة محجر الحجر

- مصنع سرعة عالية حجر محطم الصين

- الشركة المصنعة كسارة الرمال الجميلة من إيطاليا

- آلة طحن giustina

- تصنع المطاحن للتعدين

- الذهب كسارة الصخور التعدين الموردين في بيرو

- ورقة تدفق مصنع معالجة الذهب مع cil

- آلة صنع الطوب الرملي السودان

- مبيعات المعدات الثقيلة في الجزائر

- تستخدم كسارات الصخور للبيع

- مخططات التدفق للسحق الكلي

- قائمة لو كسارة الحجر تسلمت في ولاية كارناتاكا

- استفسارات سعر كسارة

- كسارة ملموسة الزاحف

- Gold Miningpanies In Liberia

- How Does Hydraulic Cone Crusher Works

- Missouri Rogers Crusher Parts

- Cone Crusher Manufacturer Cone Crushing Cone

- Application Of Complete Sand Making Plant With Cone Crusher

- Grinding Double Flying Powder Machine

- Best Rock Crusher For Concrete Aggregate

- Where Is Iron Ore Located Malaysia

- Thermal Power Plant Process Flow Diagram

- Essar Vishakhapatnam Coal Captive Power Plant Liberia

- Blade Grinding Machine Type 127

- Price List Of 200tph Crusher In Malaysia

- Crushed Beige Aggregate

- Daftar Perusahaan Quarry Granit Di Nigeria

- Stone Crusher Carnifex