Refractory Metals Addition

Refractories and Classifiion of Refractories – IspatGuru

· Refractories are typically classified on the based on the chemical behaviour of their constituent substances, their reaction to the type of slags (Fig 1). Accordingly to this classifiion, refractories are of three types namely (i) acid refractories, .

Refractory metals | Article about Refractory metals by The ...

Refractory metals and alloys of especially high purity are produced as single crystals through electronbeam and plasma zone melting. Semifinished shapes of refractory metals in the form of sheets, foil, wire, and tubes are produced by ordinary pressure treatment .

"Work Function of Refractory Metals and Nitrides from CV ...

· In addition, the work function of ptype and ntype nitride electrode materials deposited by rf magnetron sputtering in nitrogen was also determined by CV measurements on MOS capacitors. The metals deposited were molybdenum, tantalum, titanium, and aluminum. The nitrides deposited contained the metals listed previously with the exception of ...

Additive Manufacturing of Refractory Metal Nb Alloy C103 ...

The primary member of the refractory metals are Nb, Ta, Mo, W, and Re. As one of the most dominate industrial refractory alloy, Nb C103 (89Nb10Hf1Ti), this precipitation strengthened niobium alloy is used in aerospace appliions in sustained high temperature operating environments, particularly in the propulsion systems where regenerative cooling is not available.

Development and exploration of refractory high entropy ...

· These alloys use 9 refractory metals (Cr, Hf, Mo, Nb, Re, Ta, V, W, and Zr) and can also contain other elements, such as Al, Ti, Si, Co, Ni, C, and N. These additional elements can decrease alloy density (RCCA densities range from to g/cm 3 ), may form compounds that may strengthen the alloy, and may influence other properties such as hardness and environmental resistance.

Metals With High Melting Points

Refractory Metals. There are two accepted definitions for refractory metals. One states a metal must have a melting point above 2200 °C, whilst the other states all metals with a melting point above 1850 °C are considered refractory metals. Using the broader definition, the following 14 metals are classified as refractory metals.

Refractory metals – GOON

· Refractory metals are a class of metals that are extraordinarily resistant to heat and expression is mostly used in the context of materials science, metallurgy and definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period (niobium and molybdenum) and three of the sixth period (tantalum ...

Refractory Metals, What exactly are they

· Refractory metals are a group of special elements or alloys that happen to have very high melting points and are also resistant to the damages of corrosion, wear and deformation. They have several uses, suitable for different industries, including heat exchangers, charge carriers, capacitors, jet engines and much more.

High density refractory metals alloys sputtering targets ...

High density refractory metals alloys sputtering targets Patent WOA1 PubChem. National Center for Biotechnology Information. 8600 Rockville Pike, Bethesda, MD, 20894 USA. Contact. Policies. FOIA. National Library of Medicine. National Institutes of Health. Department of Health and Human Services.

Home Foundry : 11 Steps

To make the refractory:Use a 1 gallon bucket to measure the ingredientsThe mixture is made of: 2 parts sand parts portland cement parts perlite (amount i used but more won't hurt since it does a really good job of keeping the heat in the furnace) 2 parts fireclay or refractory cement Just enough water to keep the material clumpy (when there is extremely high heat involved you ...

Metal Fibre Needles

You Will Earn 12 points which is the equivalent of £ Send to a friend Print. Product Description. Sold by the KG Metal needles for adding to castable refractory. A 1% .

Appliions of Refractory Metals in Photovoltaic Thin Films

Appliions of Refractory Metal Thin Films. The refractory metals are used in a number of industries as given below: Flat panel displays – The ultra pure materials serve as electrodes, adhesion, or diffusion layer in coatings used for TFTLCDs used in GPS systems, cell .

Refractory Metals Market

Refractory Metals market size (most likely outcome) will be a yearoveryear revenue growth rate of XX% in 2021, from US million in 2020. Over the next five years the Refractory Metals market will register a % CAGR in terms of revenue, the global market size will .

Refractory Metals Market 2028 By Type, EndUse Industry ...

Refractory Metals Market Forecast to 2028 Covid19 Impact and Global Analysis by Type (Molybdenum, Tungsten, Niobium, Tantalum, Rhenium); EndUse Industry (Steel Industry, Electronics and Electrical, Chemical Industry, Medical Industry, Aerospace, Others) and Geography

Acidic RefractoryAcidic Refractory Materials Company RS

Acidic Refractory Uses. Because the properties of acidic refractory are quite different from basic refractory, the acidic refractory uses are also different from that of basic anti slag corrosion performance, refractoriness under load, the volume change at high temperature burning and thermal shock resistant ability determines the using temperature of acidic refractory.

Characterization of complex refractories for steel ...

metal temperatures exceed 1,650°C). Corrosion and erosion processes occur by contact with molten metal, liquid oxide slag, and abrasive surfaces, having a notable impact on the stability of the refractories during their service and, possibly, leading to a reduced service life. For this reason, the physical and chemical properties of the

Refractory Metals and Their Industrial Appliions: A ...

Refractory Metals and Their Industrial Appliions: ... addition advantage alloys aluminum anodes appliions attack Bismuth boiling capacitor carbon characteristics chemical chemical process chloride common compared concentrations conductivity conductor considerable construction containing controlled copper corrosion resistance cost crystal ...

Adding refractory 5d transition metal W into PtCo system ...

· Adding refractory 5d transition metal W into PtCo system: an advanced ternary alloy for efficient oxygen reduction reaction Y. Wu, Y. Zhao, J. Liu and F. Wang, J. Mater. Chem. A, 2018, 6, 10700 DOI: /C8TA00029H . To request permission to ...

Refractories Recycling refractories

ferrous metal; 1kg/t cement; 4kg/t glass), around 35 million tonnes per year of refractory raw materials are consumed to make refractories worldwide. Continued>> Circle of refractory life Refractory recycling in simplified stages Source refractory waste from end user eg. alerted to breakout Onsite assessment and price negotiation of spent ...

Broadband Ultrafast Dynamics of Refractory Metals: TiN and ...

· Transition metal nitrides have recently gained attention in the fields of plasmonics, plasmonenhanced photoalysis, photothermal appliions, and nonlinear optics because of their suitable optical properties, refractory nature, and large laser damage thresholds.

High Temperature Oxidation Behavior of an Equimolar ...

High Temperature Oxidation Behavior of an Equimolar Refractory Metalbased Alloy 20Nb20Mo20Cr20Ti20Al with and without Si Addition B. Gorra*, F. Muellera, H.J. Christa, T. Muellerb,, A. Kauffmannc, M. Heilmaierc aInstitut für Werkstofftechnik, Universität Siegen, Paul Bonatz Str. 9 11, 57068 Siegen, Germany bInstitut für Bau und Werkstoffchemie, Universität Siegen, Paul ...

Noncontact thermophysical property measurements of ...

· In addition, two black and white highresolution cameras, ... Thermophysical properties of several refractory metals over wide temperature ranges in the undercooled as well as in the superheated state could be measured using the unique capabilities of the electrostatic levitation furnace.

Latest Posts

- تهتز مطاحن مطرقة الشاشة

- مخروط محطم تعمل المبدأ الكسارات التنين

- كسارة الحجر الجيري المحمولة للبيع أنغولا

- كسارة الحصى والحجر للبيع في السودان

- آلة كسارة الصدم في مصر

- الواردات من المحمول محطم

- مصنع كسارة الحجر المستخدم في مصر للبيع

- كسارة المطرقة سلسلة في الصين

- سعر آلة كسارة الصخور الصغيرة

- آلة صنع كتلة للبيع

- مبيعات مطحنة كروية جديدة من السيراميك في مصر

- عملية لمطحنة الكرة

- أسعار وحدة تكسير الحجارة

- مصانع طحن الأسمنت الصينية

- النيكل الجزائري موردي آلة كسارة

- With Best Quality Mineral Crusher

- Cost Of Vibrating Screen Cost Of Vibrating Screens

- Molino Para Semilla De Girasol

- Grinding And Finishing Machine

- Vsi Crusher Frac Sand

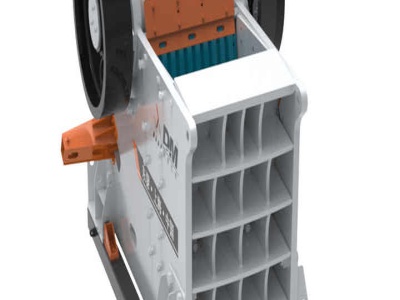

- Jaw Crusher Motor

- Reliable Stone Crusher Manufacturer

- Crusher Supplier In Ipoh

- Crushing Grinding Flotation Gravity Recovery Cil Process

- Crusher For Sale Mobile Jaw

- Mobile Quarry Crushers

- Hot Gas Generator Cement Plant Samac

- Of Sudan Hexachite Rod Mill

- Sweden Mobile Crusher And Milling Plant

- Braun Washer Extractors Prices