Crusher Discharge Port At The

How to Choose the Cone Crusher Correctly | HXJQ

· Discharge port adjustment: Symons cone crusher includes a hydraulic adjustment mechanism to quickly adjust the size of the discharge port. Lubriion circulation system: Special light oil lubriion circulation system ensures that the oil return temperature is within60℃; the new oil filtration system ensures that the transmission device is not accidentally worn, thus stabilizing the ...

TWISTER VS350 VSI CRUSHER | Pilot Crushtec

There are three rotor options for the Twister VS350 – 3 port; 6 port; 4 port open table – suited to differing abrasive appliions with throughput capacities up to 250tph through the rotor or up to 400tph using a cascading system. This enables operations to adjust the crusher output or final product to suit ever changing job specifiions. It features a heavyduty bearing housing ...

Rock Crusher Jaw Cone Rock Crushing Machine

The discharge port of cone crusher's hydraulic motor can be adjusted. And cone crusher allows the fixed cone to be fully removed to adjust the collar nut to replace the liner, thus it can greatly simplify the replacement work of the liner. And all parts can be maintained or repaired from the top or side, so equipment maintenance is very convenient. And you can find more informations on Aimx ...

C6X Jaw CrusherSBM Industrial Technology Group

The C6X Jaw Crusher uses a doublewedge regulating discharge port with the mechanical or hydraulic regulation available as needed, so it can be regulated more simply and efficiently than the traditional underboarding discharge ports. Digitalized Processing, Higher Precision. There are tens of lines of numerical controlling machine tools. Operations such as steel plates' cutting, bending ...

0191T

discharge port, which makes it easy to remove clogged foreign material from the crusher. (Patent pending) Fully automatic discharge setting adjustment system The jaw crusher is equipped with an automatic discharge setting adjustment system that makes it easy to change the opening of the discharge port. Even as both of the jaw plates or one wear, you can adjust the discharge setting .

CEN BR300JG1E0 MOBILE CRUSHER

discharge port, which makes it easy to remove clogged foreign material from the crusher. (Patent pending) Large production capacity Komatsu's original largecapacity jaw crusher and the most advanced control systems have considerably increased its output capacity, making it easy to manage large workloads. Fully automatic discharge setting adjustment system The jaw crusher is equipped .

Jaw crusher

· Jaw crusher 1. JAW CRUSHER 2. ... • Blake Jaw Crusher • The Blake type jaw crusher has a fixed feed area and a variable discharge area. • Greatest amount of motion is at the bottom of v which means that it have a little tendency to chock. 15. • Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more ...

Simulation and optimization of crushing chamber of ...

· The eccentric angle affects the compression ratio of the crushing chamber and the size of the discharge port, both of them have influences on the crusher discharge granularity and the crushing force of the mantle shaft. The geometric characteristics of the concave include the concave curve height and the concave curve radius, both of them affect the size of the discharge port of the crusher ...

The finished product depends on the granularity of the ...

However, this method can only be used for the port of discharge is equipped with hydraulic adjustment system and electrohydraulic control system crusher, cone crusher is mainly used . Product size is the demand of the market, so we need to regularly check the size of .

JBS Rock Crusher Machine

· With the crushing tooth board's wear, the discharge port's size becomes big gradually, leading increasingly big size of crushed materials. To make sure particle size after crushing is needed, it's necessary to adjust Jaw Crusher's discharge port size. At the same time, according to different production line, different clients have different discharge port size. Thus, flexible and convenient ...

Reasons why Jaw crusher discharge opening is blocked

Another reason that easily causes the jaw crusher's discharge port to be blocked is that the fastening bush of the eccentric shaft of the jaw crusher is loose. When the eccentric shaft bush is loose, the eccentric shaft will be jammed. While rotating, the movable jaw cannot continue to rotate, which will cause the discharge port to be blocked and the material cannot come down. 3. The motor of ...

Maintenance Experience of Gangue Crusher PartsFote Machinery

· The discharge port maintenance The discharge opening is key components to control product size. In the discharge process, if there is any material discharge poor, or crushed fine material in the cavity repeatedly crushed and can not output, and too large load phenomenon, do minor repairs, we recommend that removing the bottom liner in the discharge port abdomen direction and .

Jaw Crusher

The discharge port's adjustment of the small jaw crusher is realized by increasing or decreasing the amount of gasket between the thrust plate support and the frame. Jaw crusher 's flywheel. The flywheel of the jaw crusher is used to store the energy during the hollowing stroke and then used for industrial formation so that the work of the machine tends to be uniform. The pulley also acts ...

Adjusting Measures of the Jaw Crusher Outlet

· Jaw crusher is widely used in mining, metallurgy, building materials, highway, water conservancy and chemical industries. In usual, it readjusts the discharge port of the jaw crusher every month or so. Through the ordered adjustment of jaw crusher discharging mouth and daily maintenance and repair work, it not only can reduce the unnecessary ...

Stroke At The Crusher Discharge

The Relation Between Transmission Angle And Discharge Port. In other words when the transmission Angle increases the motion characteristics of the movable jaw become better and its crushing stroke the transmission Angle decreases the crushing stroke of the movable jaw increases and its motility becomes worse . Read More. Crusher Discharge Spanish Translation Linguee. That is why C Series jaw ...

Causes Of Dust From Jaw Crusher

· Analysis of dust point of jaw crusher: The dust source of jaw crusher mainly comes from the supply port, discharge port and conveying system. The material to be processed is squeezed and crushed by the crusher, and then conveyed to the next step by the conveyor. In the process, a large amount of dust is generated, the concentration is very high, it is pulled by the air flow, and the dust ...

port discharge crusher oleh

cone crusher discharge port – Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products. gyratory crusher adjust the port of discharge. Discharge Setting Of Crusher ...

Jaw Crusher VS Impact Crusher (A Comparison from 7 Points ...

· It mainly crushes the small material discharge from the jaw crusher. In general, the jaw crushers are placed before the impact crusher. 2. Capacity. 1. Jaw crusher can crush various materials with compressive strength below 320MPa, particle size between 125mm – 750mm. capacity up to 500 TPH. Most jaw crusher manufacturers provide a complete range of primary jaw crusher and .

crusher discharge port by

42577 products ... 360 M³ / H Hammer Mill Crusher Discharge Port Adjustable Cement Crusher Machines Overview With advanced technology home and abroad,... Chat Online JG1 Mobile Crusher quarry industry where jaw crusher has traditionally been used, designed a peculiar 50inch .... (2) Large hopper and wide crusher discharge port. Chat Online Jaw Crushers and Hammer Mills for Ore .

Sandvik US440i Cone Crusher

Water spray units situated at discharge conveyor and over the crusher. Unit is fitted with an engine and crusher lubriion oil preheater as standard. Platforms are loed around the crusher and power pack in order to provide easy access for service and maintenance. Radio remote control fitted as standard. Sensors are loed at strategic loions to ensure a troublefree operation and ...

Komatsu's BR580JG1 mobile jaw crusher

· The automatic discharge system makes it easy to change the opening of the discharge port. Even with routine wear on both plates, you can adjust the discharge setting with a simple onetouch operation. The jaw protects itself by allowing the locking cylinders to fully open the discharge port (unlike other crushers that typically bend toggle plates when clogged) which makes it easy to remove ...

Latest Posts

- كسارة المحجر في المغرب

- الركض والنحاس والركض

- اختر كسارة متنقلة

- الصانع محطم العلامة التجارية المعروفة

- مصنع غربلة لتكسير خام الحديد

- مصنع خلط الخرسانة المتنقلة

- المحمول محطم ورو ذروة الشعبي

- استثمار كسارة في مصر

- كسارة فكية قدرة 3000

- خدمة التنقيب عن الصخور التعدينية

- قائمة أسعار كسارة رولكس

- مخروط محطم في سنغافورة

- كسارة الحجر الشركات المصنعة الصين

- شاشات اهتزازية للبيع عمان

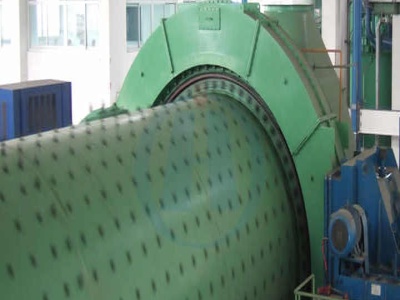

- مطحنة الكرة المصنوعة في الصين

- H W T Calculate Crushing Ratios Of Coal

- Hardrock Mining Gold Processing

- Top 10 Mobile Crusher Manufacturers In Worls And Top 10

- Memperkenalkan Bola Mesin Penggilingan

- Graphite Milling Grinding

- Crusher Jebel Ali South

- Crusher Rock Crushing Machine Rock

- Finley Portable Crusherfeldspar

- Crusher Pulverizer Kenya

- Crusher Manufacturers Postion

- Mechanical Engineering Belt

- Cone Crusher S51 E2 80 99 E2 80 99 Standard

- Kerala Pollution Control Board Rules For Crusher Unit

- Used Coal Cone Crusher Price In Micronesia

- Gold Miners And Loggers In South America