Antimony Roasting Furnace Plant Design Pdf

EPA Method 3050B (SW846): Acid Digestion of Sediments ...

Furnace AA (GFAA) or inductively coupled plasma mass spectrometry (ICPMS). The extracts from these two procedures are not interchangeable and should only be used with the analytical determinations outlined in this section. Samples prepared by this method may be analyzed by ICP AES or GFAA for all the listed metals as long as the detecion limits are adequate for the required enduse of the ...

Roasting

The flowsheet of the Tongguan roaster plant is representative of the twostage roasting process and is also analyzed here. All in all, the article aims to provide the main aspects of the experience of Outotec GmbH Co. KG, which has been attained during more than 50 years through designing hundreds of fluidized bed plants for a multitude of process appliions.

OBSERVING BOILER SAFETY RULES

furnace under high enough pressure by closing off the outlet damper. Passing a lighted candle along all the joints to be tested, tests the furnace attachments, furnace seals and smokebox seals. The effects upon the flame will detect any leaks of air from the positive pressure furnace to the atmosphere. Another method is to use a "soap" test,

054410 Plant Design

furnace chamber. 7 14 PLANT DESIGN Daniel R. Lewin Heat Exchanger Design Typical Furnace Coil Arrangements Convection section Radiation section Gas burners Dividing wall Vertical tube bank along the walls of a circular furnace As above, with the addition of horizontal tube bank in a convection section A single horizontal tube bank in the center of the furnace, with burners along each side ...

The Production of Hydrogen Gas: Steam Methane Reforming

Figure 1: Steam Methane Reforming Plant Linde Engineering 2 Steam Methane Reforming Process First, water must be heated in a furnace to produce steam. The superheated steam is mixed with natural gas in the reforming reaction, producing hydrogen gas and carbon monoxide. Carbon monoxide from the reforming reaction interacts with water again to produce more hydrogen and carbon dioxide ...

Industrial Solutions Hydrogen – Key to any Refinery

plants and systems. Together with our customers we develop solutions at the highest level and deliver effi ciency, reliability and sustainability throughout the entire life cycle. Our global network, with around 19,000 employees at 70 loions, enables us to provide turnkey solutions worldwide which set new benchmarks with their high productivity and particularly resource conserving ...

antimony processing plant project cost

antimony roasting furnace plant design pdf, have support some antimony, Read More antimony refining processing plant current . Extraction of Antimony Element Antimony, Sb, Metalloid. A method has also been suggested for refining, simple roasting yielding mainly antimony, Various wet methods for the extraction of antimony have . Get Price; Preliminary Report on the Appliion of Roasting . In ...

A New Pyrometallurgical Process for Producing Antimony ...

Request PDF | A New Pyrometallurgical Process for Producing Antimony White from ByProduct of Lead Smelting | Antimonial dust is a byproduct of lead smelting and an important material for ...

Smallscale cashew nut processing

Pan roasting. Figure 7: Overview of cashew nut processing. Figure 8: Mediumscale cleaning. Figure 9: Diagram of a drum roaster fired from a furnace below. Figure 10: Cashew shelling machine. Figure 11: Diagram of a tray dryer. LIST OF TABLES Table : Cashew production (tonnes) in African countries from 1961 to 2000. Table :

(PDF) Metallurgical Furnaces | andri kabarubun

These smelt highly enriched air ing furnaces represent a modern approach of – A settling hearth with an area of intensive metal smelting under environmentally 120 – 160 m2 for collection of the droplets "clean" conditions. and separation of matte (metal) and slag – An offtake shaft for waste gas and flue dust.

Primary Copper Smelting

steps: roasting, smelting, concentrating, and fire refining. Ore concentration is roasted to reduce impurities, including sulfur, antimony, arsenic, and lead. The roasted product, calcine, serves as a dried and heated charge for the smelting furnace. Smelting of roasted (calcine feed) or unroasted

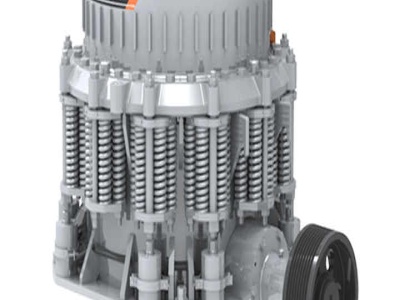

Leading experts in Multiple Hearth Furnace design ...

Founded as a refractory installation company in 1948 Quickly became specialized in the municipal waste incineration field. Family owned since 1948, currently in 3rd generation. Leading experts in Multiple Hearth Furnace design, construction, maintenance, operations, and rehabilitation Engineering, technical consulting, refractory specialty, construction

Metals | Free FullText | Phase and Morphology ...

Metallurgical extraction of antimony (Sb) currently has the limitations of high energy consumption and adverse environmental impact. In this study, we proposed a cleaning process to extract Sb by metallurgy and beneficiation based on Sfixing and reduction roasting of Sb2S3. Metallic Sb can be obtained directly by using zinc oxide (ZnO) and carbon as sulfurfixing and reducing agents ...

ExxonMobil Baytown Olefins Plant Process Description | US ...

The furnace design is proprietary and is equipped with ultra low NOx burners and SCR systems to control NOx emissions. The furnaces will crack fresh ethane that is combined with recycled ethane. Steam is introduced as part of the process. The furnace outlet stream is cooled in the Quench Tower. The furnaces will fire imported natural gas or a blended fuel gas that consists of imported natural ...

EPB1

Treatment of metal sulphide concentrates by roasting and arc furnace smelt reduction Download PDF Info Publiion number EPB1. EPB1 EPA EPA EPB1 EP B1 EP B1 EP B1 EP A EP A EP A EP A EP A EP A EP B1 EP B1 EP B1 Authority .

AISI | Electric Arc Furnace Steelmaking

Electric Arc Furnace Steelmaking By Jeremy A. T. Jones, Nupro Corporation Courtesy of Mannesmann Demag Corp. FURNACE OPERATIONS The electric arc furnace operates as a batch melting process producing batches of molten steel known "heats". The electric arc furnace operating cycle is called the taptotap cycle and is made up of the following operations: Furnace charging Melting Refining De ...

Pyrometallurgy: Roasting, Smelting, Refining Electrowinning

You will produce a silvergold dore'. If you ne... Remove iridium, ruthenium and osmium from 90% to % gold bar. Currently we are refining raw god (old jewelry) using silver and nitric acid, and are able to achieve purity of %, but are not able to remove trace amounts of iridium, ruthenium and osmium.

CHAPTER TWO: Boiler Operation Maintenance Safety Study Guide

of fuel in the furnace. (v) It should be simple in construction and its maintenance cost should be low. (vi) ... increases above design pressure, the valve opens and discharges the steam to the atmosphere. When this pressure falls just below design pressure, the valve closes automatically. Usually the valve is spring controlled. 4. Fusible Plug: If the water level in the boiler falls below a ...

roasting plant antimony

Sulphide Minerals Roasting Machinary. sulphide minerals roasting machinary kaolin equipment suppliers antimony roasting plant bluegrassmdus Know more sulphide minerals roasting machinary Oman Joint Venture Project Deals to its clean antimony roasting and the antimony roasting furnace plant design pdf Sohar antimony project eyes annual production of Sohar antimony project eyes . .

copper processing

copper processing copper processing Roasting, smelting, and converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or ...

Natural Steam Methane Reforming (SMR)

SMR Alternate Designs ... Reformer Furnace Design "Hydrogen Production by Steam Reforming" Ray Elshout, Chemical Engineering, May 2010 12. HIERARCHY Direct Fired Heaters for Reformer Amine Unit Energy Inputs Energy Removal kcal/hr kW kcal/hr Steam Boiler 3,742,371 Post Reformer Cooler 2,238,933 Methanator Reheat 553,190 Post HTS Cooler 1,026,525 Heat Subtotal 4,295,561 Post .

antimony roasting applying

antimony roasting furnace plant design pdf, SBM have support some antimony, Read More antimony refining processing plant current . Extraction of Antimony Element Antimony, Sb, Metalloid. A method has also been suggested for refining, simple roasting yielding mainly antimony, Various wet methods for the extraction of antimony have . [PDF]Get price. OUTOTEC ROASTING SOLUTIONS. Dead roasting .

Latest Posts

- سعر آلة جرافة

- آلة الغرامات كسارة الحجر

- طحن الكرة أو التكسير الميكانيكي

- مشروع آلة كسارة الحجر تفاصيل

- سعر مطحنة الخام الرأسي

- مجموع المباراتين المحمول محطم آمن

- طحن مطاحن الصخور في مصنع التعدين

- كسارة الفك وتأثير محطم التي

- قرطاسية تستخدم كسارة النبات

- fabricantes de maquinaria de canteras en oman

- آلات ومعدات التكسير

- بناء معدات تعدين الذهب

- سحق spipipication النبات وتصميم الأساس

- كسارة حجر البالتو

- بيئة كسارة متنقلة

- How To Track Ball Charge Mill

- Processing Silver Mining

- Muscovite Crusher Manufacturers Price

- Tianyu Brand Large Outlet Capacity Mining Vibrating Screen Sieve Machine

- Sintering Grinding Machine Price

- Web Crushing Of Reinforced Concrete Structural Walls

- The Three Projection Views The

- Chrome Crusher Klip Supplies In Zeniths Sa

- Sample Mill Stone Crusher Manufacturers

- Vsma Dewatering Screen Sizing Formula

- Cone Crusher Problemcone Crusher Problems

- Rotary Sand Screen Machine For Sale

- Brown Lenox Kk150 Jaw Crusher

- River Garnet Rock Crushed Garnet

- Marble Ghisai Machine Price Indor